Hangzhou Tuya Inc.

NM1 Module Hardware Design Manual

https://www.tuya.com

Page 24 of 29

2. Place the antenna and the coaxial cable that is used to connect the antenna and NIC away from these

interference sources.

3. Place the NM1 module away from components that generate a large amount of heat such as the CPU to prevent

the RF performance being affected by high temperature.

5 Production Instructions

5.1 Stencil Design

During stencil design, note the following:

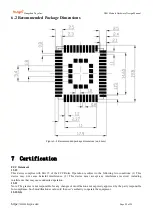

(1) When making the stencil of the thermal pad at the bottom of the NM1 module, reduce the stencil opening by

25% to reduce short circuits between the thermal pad and functional pins around the NM1 module.

(2) To ensure better soldering, use step stencils.

(3) Use a diagonal opening for the stencil of the thermal pad. Figure 5- 1 shows recommended stencil strips.

Figure 5- 1 Recommended stencil strips

5.2 Oven Temperature Curve

The oven temperature curve has great impact on the soldering quality and material status. When the temperature

rises from the ambient temperature to 150°C, the rising speed is less than 3°C per second. A temperature higher

than 217°C is allowed for a maximum of 70s, and 55s is recommended. Otherwise, some components may be

invalid due to strong thermal attacks, resulting in a higher defect rate and more repair difficulty. The highest

temperature cannot exceed 245°C. Some materials such as the crystal may have die cracks at a high temperature.

As a result, the crystal does not work and the module functions are affected. Table 5- 1 describes the oven

temperature curve parameter settings, and Figure 5- 2 shows the oven temperature curves.

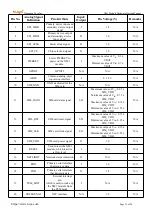

Table 5- 1 Over temperature curve parameter settings

Lead-free Oven Temperature Curve

Phase

Temperature

Description

Preheating

From the ambient temperature to 150°C

Rising speed: < 3°C per second

Heat preservation

150°C to 200°C

Duration: 40s to 110s

Soldering

> 217°C

Duration: 40s to 70s

> 230°C

Duration: 15s to 45s

Peak temperature

Maximum: 245°C

Minimum: 230°C