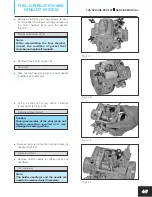

Fig. 4.24

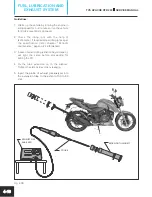

Fig. 4.25

l

After cleaning the carburettor pages properly

using the cleaner, blow the compressed air to

clean the passages throughly. (Fig. 4.24)

Caution:

Do not use wires to clean the jets.

R e m o v e a l l r u b b e r p a r t s f r o m t h e

carburettor assembly before cleaning it

with a cleaning solution. This will prevent

damage or deterioration of the rubber

parts.

D o n o t u s e c o m p r e s s e d a i r o n a n

assembled carburettor which may cause

damage to the float system.

INSPECTION

Needle valve assembly

l

Any foreign particles on float needle (needle

valve assembly) and its seating may cause

improper sealing resulting in over flow of

petrol. Similar kind of problem also occur in

case of float needle and its seating area are

worn-out.

l

Conversely if the float needle sticks, the petrol

does not flow into the float chamber.

l

If the float needle is worn-out as shown

(Fig. 4.25) replace it with a new one.

l

Inspect piston valve, needle jet, jet needle,

pilot jet, main jet, pilot screw and ‘O‘ rings for

any wear or abnormal damage. If any damage

is noticed, replace damaged parts with new

ones.

REASSEMBLY

l

Reassemble parts in the reverse order of

dismantling procedure while ensuring the

following.

l

Refer carburettor assembly exploded view on

page

for assembly details.

no. 4-4

Note:

Ensure that the pilot jet is not tightened

too much as this will cause damage to its

head. Removal from the mixing body

becomes very difficult.

4-9

TVS APACHE RTR 200

SERVICE MANUAL

FUEL, LUBRICATION AND

EXHAUST SYSTEM