TVS APACHE RTR 200

SERVICE MANUAL

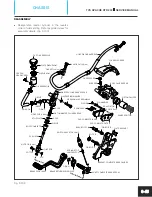

CHASSIS

6-31

l

Heat the drum rear sprocket on a hot plate to

approximately 125° C. (Fig. 6.91A)

Hot plate

l

Draw out ball bearing, from drum rear sprocket

along with the shaft rear sprocket. (Fig. 6.91B)

Drift

Nylon hammer

INSPECTION

Before inspection, clean all the components with

kerosene and lubricate the bearings immediately

after cleaning.

l

Inspect wheel bearings, axle complete rear

and alloy wheel rear (refer page no. 6-2 for

checking procedure).

l

Clean and inspect the drive chain as explained

in chapter ”Periodic maintenance” page 2-32.

Sprocket rear

l

Inspect sprocket rear teeth for wear. If they are

worn-out as illustrated (Fig. 6.92), replace the

sprocket with a new one.

Absorber rear wheel hub shock

l

Inspect the absorber rear wheel hub shock for

wear, deformation or damage and replace with

new if required. (Fig. 6.93)

Tyre inflation pressure

l

Tyre inflation pressure affects the tyre life to a

great extent. So it is necessary to maintain the

proper tyre pressure. (Fig. 6.94)

Tyre pressure gauge

Tyre pressure

2

Solo riding

2.00 kg/cm (28 PSI)

2

Dual riding

2.25 kg/cm (32 PSI)

Note:

Tyre pressure should be checked when the

tyre is cold. Low tyre pressure consumes

more fuel.

Fig. 6.91A

Fig. 6.91B

Fig. 6.92

NORMAL

WORN-OUT

Fig. 6.93

Fig. 6.94