l

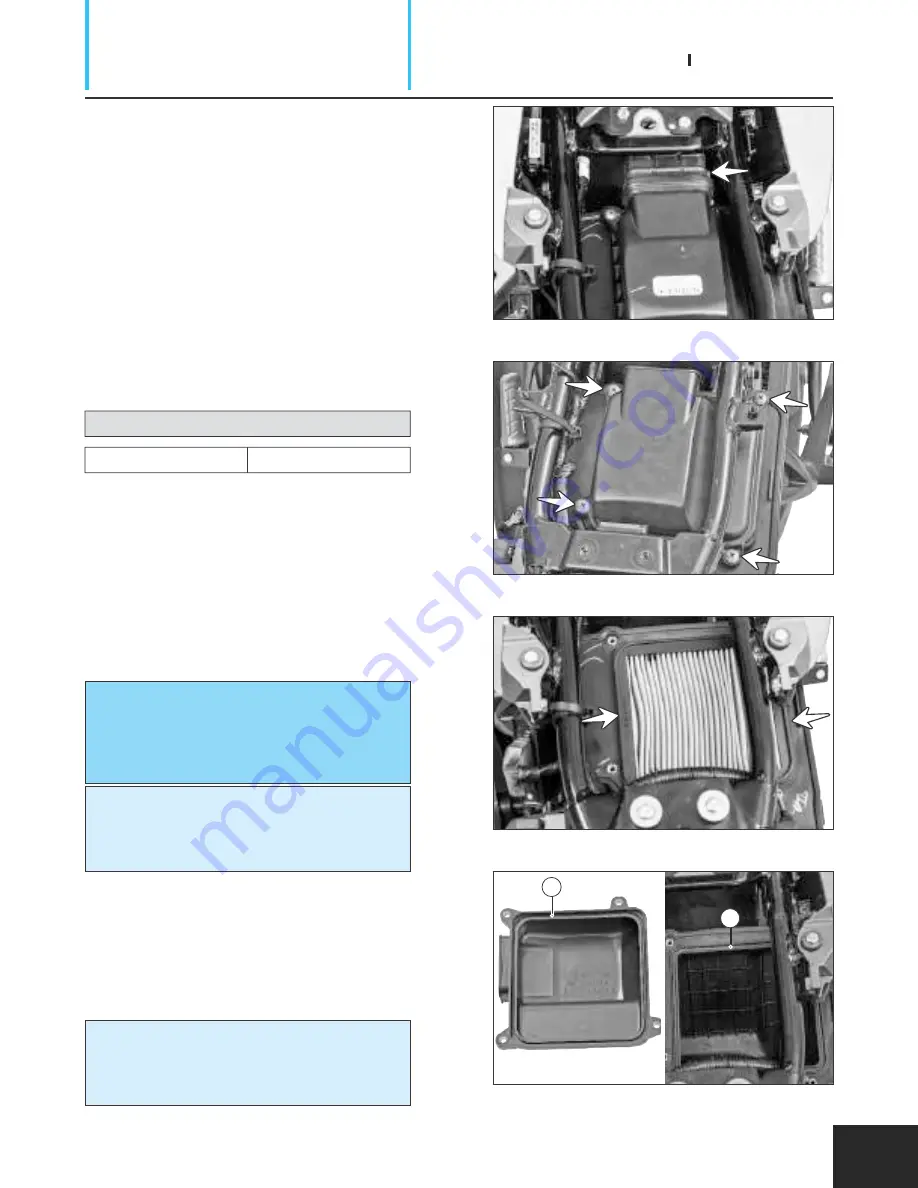

Disconnect the tube inlet from the cover filter

element. (Fig. 2.40)

l

Remove the CRR pan head screw (M5x16 -

4 nos.) from the cover filter element. (Fig. 2.41)

Phillips head screw driver

Tightening torque

2 ± 0.2 Nm

l

Take out the cover filter element from the

case air cleaner complete.

l

Remove and inspect the air cleaner element

for any blockage / abnormality. Replace the

element if any block or damage is found.

(Fig. 2.42)

Caution:

Do not wash or clean the air cleaner

element. It needs only replacement.

However the air cleaner element must be

replaced at every 12000 km.

Note:

While removing / reassembling the air

cleaner element do not hold the paper

element portion. Hold only at the sides.

l

Inspect and ensure that the cover air cleaner

and case air cleaner assembly is clear from any

dust, dirt and foreign particles. (Fig. 2.43)

l

Before reassembling the air cleaner element,

clean the case air cleaner and cover air cleaner

using a cloth and cleaning solvent.

Note:

Before reassembling the cover, ensure the

availability and the intactness of seal

cleaner (A & B) in both cover and the case.

TVS APACHE RTR 200

SERVICE MANUAL

PERIODIC MAINTENANCE

2-17

Fig. 2.40

Fig. 2.41

Fig. 2.42

Fig. 2.43

A

B