6

SAFETY AND OPERATING INSTRUCTIONS

89200016

Lock Collar

Spring Washer

Snap Ring

4. Slide the Stainless Steel Sleeve onto the conductor tube end.

5. Align the set screw with the threaded hole in the conductor tube and tighten

until the screw bottoms out. Do not overtighten.

The conductor tube Stainless Steel Sleeve replacement is complete. Trim the

conduit and install the consumables.

5.04

REPLACE CONDUCTOR TUBE

The conductor tube is attached to the MIG Gun handle by two set screws on the side of the

handle. To remove:

1. Remove the front end consumables from the conductor tube.

Loosen the conduit liner set screw with a 5/64" hex wrench supplied and then

loosen the socket head cap screw securing the conductor tube in place inside

the handle with a 5/32" hex wrench. Refer to the figure below.

2. Remove conductor tube.

Conductor Tube set screw

3. Mount the conductor tube O-ring on the end of the conductor tube.

Slide the tube over the liner and insert into the brass connection within the

handle. Tighten the socket head cap screw wrench tight using the 5/32" hex

wrench.

4. Tighten the conduit set screw down against the liner. Do not overtighten to

avoid damages the liner.

5. Check the length of conduit extending from the conductor tube front end and

adjust if necessary.

There are two methods of trimming the conduit. See "Conduit Installation" on

page 5.

SECTION 6: CABLEHOZ® REPAIR

6.01

CABLEHOZ® REPAIR

If you should find it necessary to repair Cablehoz connection(s), repair instructions can be

found at

www.Tweco.com

our website.

RED

WHITE

BLACK

BLACK

RED

WHITE

BLACK

BLACK

TRIGGER

NOT USED

NOT USED

BLUE

BROWN

CONTROL WIRE

CABLEHOZ

{

SECTION 7: TROUBLESHOOTING

Contact tips and nozzles should be cleaned frequently. Spatter buildup may cause bridging

between nozzle and tip. This could cause electrical shorting between the nozzle and work

piece as well as poor or improper gas flow. Regularly inspect the conductor tube, handle,

cable, and other parts of the MIG Gun for abrasion, cuts, or undue wear. Replace or repair

any parts found deficient. Refer to

www.Tweco.com

for MIG Gun troubleshooting chart(s).

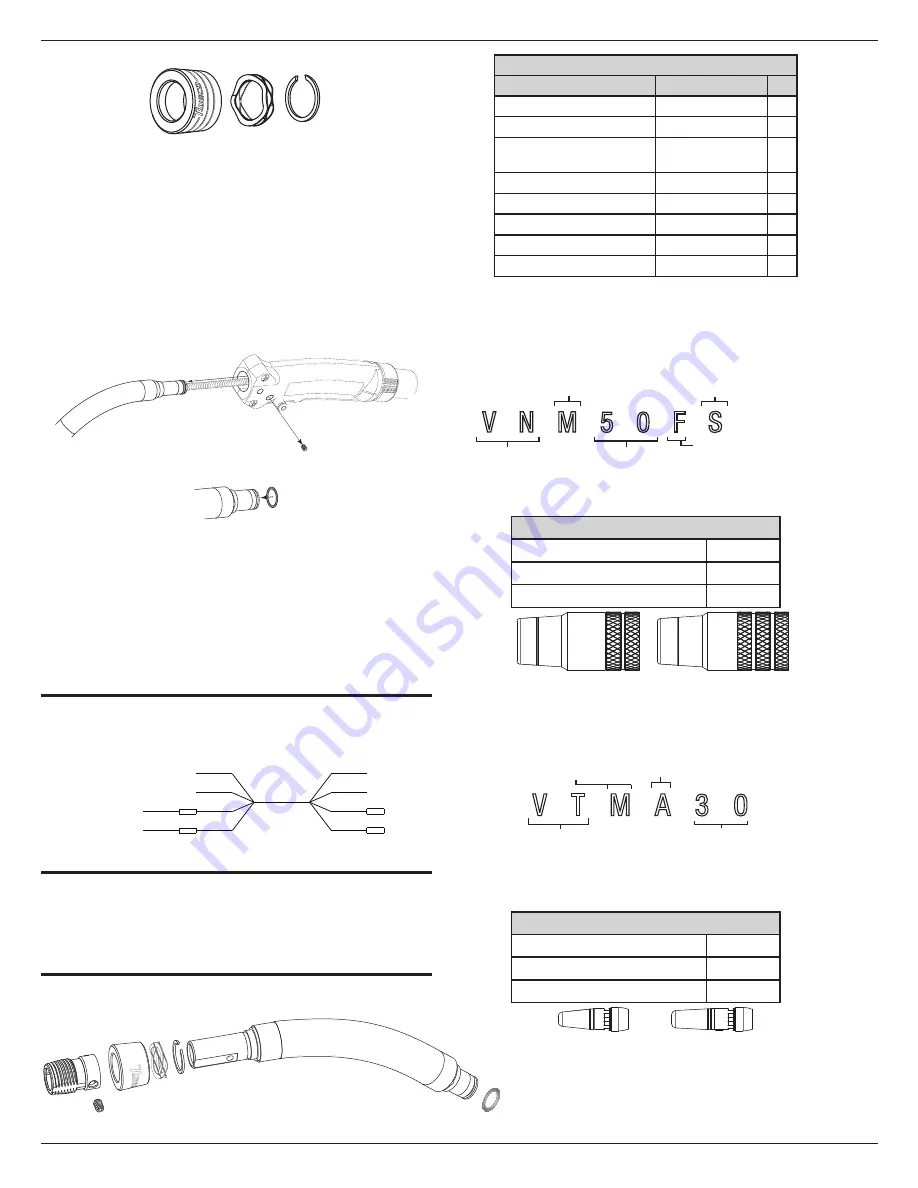

SECTION 8: CONSUMABLES

8.01

REPLACEMENT KITS

Conductor Tube

O-ring

Set Screw

Retaining Ring

Wave Spring

Stainless

Steel Sleeve

Lock Collar

Spray Master Replacement

Kit Parts List

Description

Part No.

Qty

Conductor Tube Assy.

SMVCT60

1

Set Screw* (Sleeve)

V41CS

1

Set Screw (5/64" hex

wrench drive)

41CS

1

Retaining Ring

PMA64RS

1

Wave Spring

VCTLSPR

4

Lock Collar

VCTLSLK

1

Stainless Steel Sleeve

VCTLSL

1

O-Ring

94-710-036S

1

* Not Shown

8.02

TIPS AND NOZZLES

Velocity Nozzle Identification

V N M 5 0 F S

Velocity

Nozzle

Blank=Std Recess

F=Flush

P=Protrude

R= Recess ¼” (6.35mm)

FAS=Spot Weld

FC=Flux Core

S=Light Duty

M=Medium Duty

H=Heavy Duty

ET=Extended Taper

Orifice Opening Size:

37

=3/8”

62

=5/8”

50

=1/2”

75

=3/4”

Blank= Fixed Threaded

S=Adjustable Slip

Nozzle Convention

2 Knurl Rings

VNM

3 Knurl Rings

VNH

4 Knurl Rings

VNET

Medium Duty Heavy Duty

Velocity Contact Tip Identification

V T M A 3 0

Velocity

Tip

S=Light Duty

M=Medium Duty

H=Heavy Duty

ET=Extended Taper

A=Alum

Blank=Other

Wire Size:

364

=3/64”

23

=0.023”

116

=1/16”

30

=0.030”

564

=5/64”

35

=0.035”

332

=3/32”

40

=0.040”

764

=7/64”

45

=0.045”

18

=1/8”

Contact Tip Convention

2 Rings

VTM

3 Rings

VTH

4 Rings

VTET

Medium Duty Heavy Duty