-

16

TWIN BUSCH GMBH

Technical changes, errors and printing mistakes are reserved. V01_NK_418_EN

Do not place any vehicle on the lift in the case of trial running.

3.

General Installation Steps

Step1: Choose installation site.

Use a fork lift to place the machine at installation site as required. See Annex 1 for space requirements on the installation site.

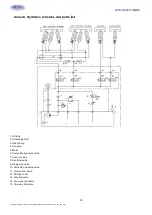

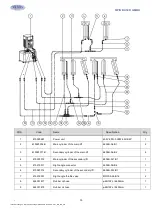

Step 2: Connect hydraulic oil hoses.

Connect the oil hose as per the scheme for oil hose connection. (This step is very important and it is quite necessary to

understand the diagram of oil hose connection before operation)

Step 3: Connect pneumatic hoses.

Connect the pneumatic release system by the scheme of pneumatic hose connection.

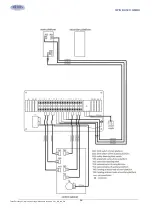

Step 4: Connect electrical wires.

Refer to the electrical connection scheme. Connect the power supply and the quick connecters for limit switch.

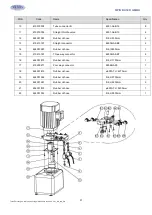

Step 5: Fill with hydraulic oil.

ONLY CLEAN AND FRESH OIL

ONLY

Attention:

Lift must be fully lowered before changing or adding hydraulic oil

Normally it needs 22 liters of hydraulic oil.

Initially, fill the tank full with about 18L of hydraulic oil . Run the main and the secondary lift for several cycles and add another

4L into the tank.

Note

:

As running speed of the lift is mainly decided by the density hydraulic oil, we suggest using NO.46 hydraulic oil when

average

Temperature of the location is above 18 degree Celsius and using NO.32 hydraulic oil when temperature is below 18 degree

Celsius.

Step 6: Leveling

Check the connection of the hydraulic and electrical system before leveling operation

Review operation instructions and get familiar with lift controls by running the lift through a few cycles before leveling operation.

Leveling platforms of the main lift

1)

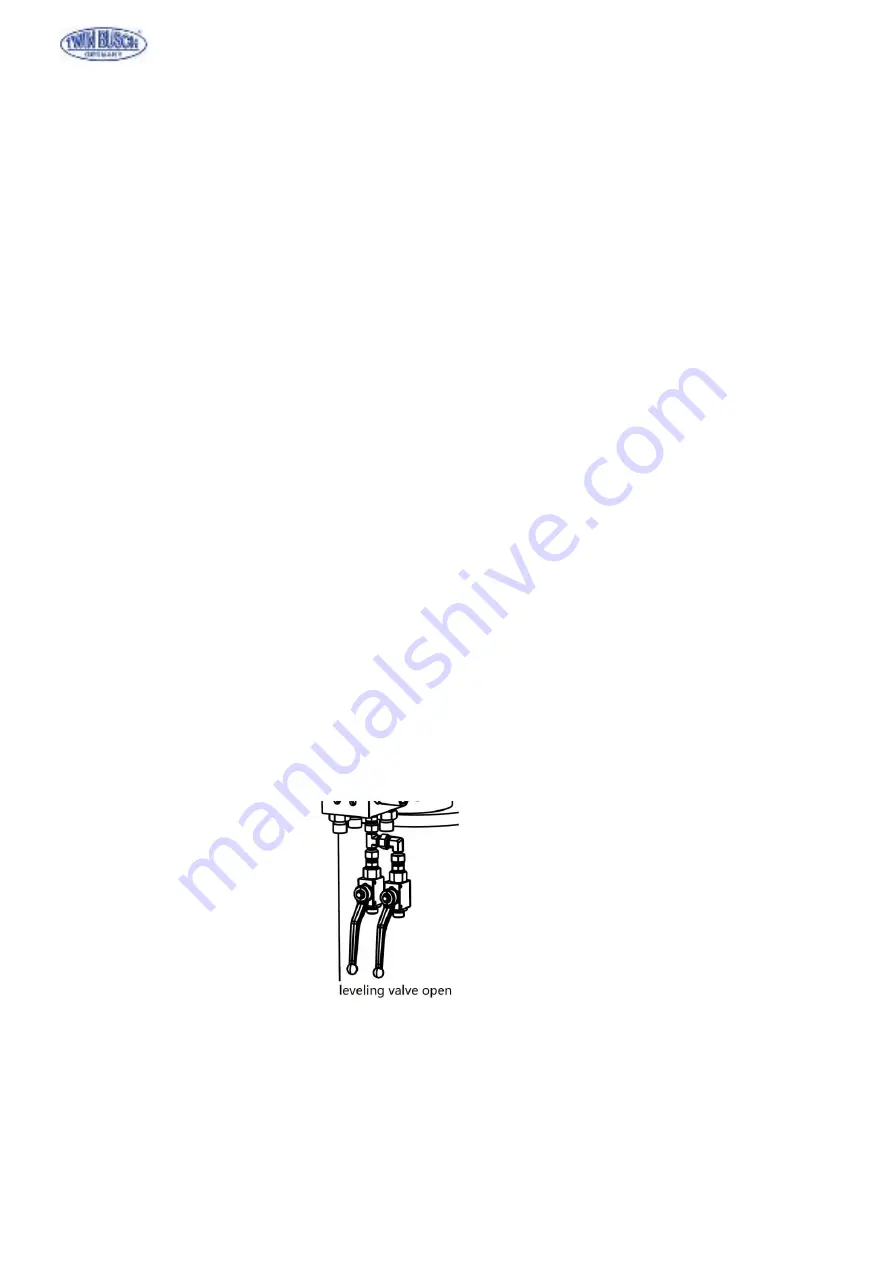

Turn on the main power switch and turn the selection switch SA2 to the main lift and SA1 to “Leveling” status. Turn the two

handles of leveling valve to the following status.

2) Push the UP button to raise the platforms to the max height and then lower to the minimum height. Repeat this for 3 cycles. Pay

attention to push the UP button very slightly and slowly when the platforms almost reach to the max height. After that, engage the

mechanical safety locks and push DOWN I and DOWN II to completely lower the platforms. This step may needs pretty long time

as there remained air in the oil cylinders and no load on the platforms.

3) Repeat the cycles of step 2 for two or three times. Turn off the two leveling valves when platforms are fully lowered. Turn the two

handles to the following status.

Summary of Contents for TW SA 42 U V2

Page 1: ......

Page 2: ...TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...

Page 23: ... 24 TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...

Page 24: ... 25 TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...

Page 25: ... 26 TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...

Page 40: ... 41 TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...

Page 47: ... 48 TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...

Page 48: ... 49 TWIN BUSCH GMBH Technical changes errors and printing mistakes are reserved V01_NK_418_EN ...