2

Twin City IM-4050

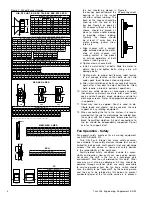

Wall Fan Installation

1. Your wall fan is shipped with a wall mounting brack-

et. Refer to the wall fan dimensional drawing on

page 4 for mounting hole locations. Consideration

should be taken when choosing wall fan location

with regard to other buildings, parking lots, etc.

2. After drilling pilot holes, bolt the wall mounting

bracket to the wall through the holes provided on

the bracket flange using eight (8) lag bolts.

3. Position fan with the motor compartment breather

tube facing downward.

NOTE:

On Models BCRWR

and DCRWR, the breather tube can be facing

downward or towards either side. Do not install with

breather tube facing up.

4. Run wires through conduit to switch. Leave some

slack in the wire in the motor compartment so that

the motor and wheel assembly can be lifted for

inspection and cleaning. If fan has an external dis-

connect switch (standard on restaurant units) bring

power to switch.

5. Bolt the fan base to the wall bracket using hardware

provided.

6. Make connection to the disconnect switch per

above electrical instructions.

7. Restaurant fan installation must be in compliance

with local codes and the National Fire Protection

Association’s NFPA-96.

8. Models DCLH, DCLP, DCRD, DCRU, DCRUR,

BCLH, BCLP, BCRD, BCRD-E, BCRU, BCRUR and

BCRUSH are not designed to be mounted to a wall.

Electrical Connection

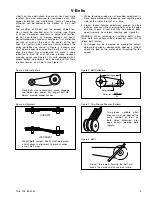

1. Connect supply wiring to the disconnect switch

(non-fused standard). Check the wiring diagrams on

the motor for connections.

2. The motor is factory set at the voltage marked on

the fan nameplate. Check the line voltage with the

nameplate voltage and wiring diagrams.

3. The main power wiring should be sized for the

ampacity shown on the dataplate. Size wires in

accordance with the ampacity tables in Article 310

of the National Electrical Code. If long wires are

required, it may be necessary to increase wire size

to prevent excessive voltage drop. Wires should be

sized for a maximum of 3% voltage drop.

CAUTION:

Use copper conductors only.

CAUTION:

Protect wiring from sharp edges. Leave

some slack in the line to prevent damage.

4. Disconnect switches are not fused. The power leads

must be protected at the point of distribution in

accordance with the fan dataplate.

5. On fans without a thermal protector integral to the

motor (refer to unit or motor dataplate to determine

if protector is present) a separate overload device

is required. Refer to Sections 430-32 of the N.E.C.

for sizing.

6. All units must be electrically grounded in accordance

with local codes or, in the absence of local codes,

with the latest edition of the National Electrical

Code (ANSI/NFPA 70). A ground lug is provided as

standard in the unit terminal box. Size grounding

conductor in accordance with Table 250-95 of the

National Electrical Code.

DO NOT

use the ground

lug for connecting a neutral conductor.

7. Supply voltage to the power ventilator should not

vary by more than 10% of the value indicated

on the unit dataplate. Phase unbalance must not

exceed 2%.

WARNING:

Failure of motor due to operation on

improper line voltage or with excessive phase unbal-

ance constitutes product abuse and may cause

severe damage to the unit’s electrical components.

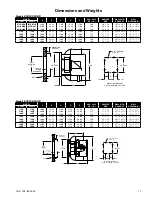

SIZE

SHIP MOTOR LOOSE

070D – 160D

100HP – 160HP

• Motor HP larger than shown on TCF&B Price

List P-4105

180D – 240D

180HP – 210HP

• 143T and larger – ODP/TE Cast iron frames

• 145T and larger – ODP/TE Rolled frames

• 143T and larger – Explosion-proof motors

300D – 360D

240HP – 300HP

• 182T and larger – ODP/TE Cast iron frames

• 184T and larger – ODP/TE Rolled frames

• 182T and larger – Explosion-proof motors

420D – 480D

360HP, 540

• 184T and larger – ODP/TE Cast iron frames

• 213T and larger – ODP/TE Rolled frames

• 184T and larger – Explosion-proof motors

BCRD, BCRD-E, BCLH, BCLP

Larger motors will ship loose in order to prevent shipping damage, per the following charts.

SIZE

SHIP MOTOR LOOSE

110B – 160B

140HP – 160HP

• 143T and larger – ODP/TE Cast iron frames

• 145T and larger – ODP/TE Rolled frames

• 143T and larger – Explosion-proof motors

180B – 240B

180HP

• 145T and larger – ODP/TE Cast iron frames

• 182T and larger – ODP/TE Rolled frames

• 145T and larger – Explosion-proof motors

300B – 360B

210HP – 300HP

• 182T and larger – ODP/TE Cast iron frames

• 184T and larger – ODP/TE Rolled frames

• 182T and larger – Explosion-proof motors

420B – 480B

360HP

• 184T and larger – ODP/TE Cast iron frames

• 213T and larger – ODP/TE Rolled frames

• 184T and larger – Explosion-proof motors

BCRU, BCRUR, BCRUSH, BCRW, BCRWR

Shipment of Motors