Twin City Engineering Supplement ES-52

3

Additional.instructions.may.be.given.for.some.fan.models,.

components.and.accessories.in.the.appendix.

Fan Installation – Disassembled Units

A. unit. is. considered. “disassembled”. if. any. component.

required.for.proper.operation.is.shipped.or.supplied.sepa-

rately.or.in.pieces..Reference.earlier.instructions.concerning.

proper.handling.of.fan.components.

Instructions.for.Mounting.and.Assembly.of.Unit:

1..Move.lower.housing/framework.to.mounting.location.

2..If.vibration.pads.or.bases.are.used,.place.on.bolts.first..

Place.lower.housing.assembly.onto.bolts.

3..Level.and.shim.if.required..Bolt.into.place.

4..If.separated.pedestal.or.bearing.pedestal:

a..Bring.bearing.pedestal.to.desired.location.

b..Place. any. vibration. base. or. pads. into. place.. Set.

bearing.pedestal.on.bolts.

c..Never.distort.bearing.pedestal.by.forcing.it.to.align.

with.a.non-level.surface..Shim.beneath.the.pedestal.

as.required.

d..Check. bearing. centerline. height.. Change. centerline.

height. to. match. centerline. height. of. housing.. High.

temperature.units.may.require.the.housing.centerline.

to. be. lower. when. cold. so. that. it. will. be. centered.

when.hot.

e..Measure. from. housing. to. bearing. pedestal. to. bring.

bearing. pedestal. into. square. with. housing. (a. large.

square.may.also.suffice).

f... Bolt.into.position.

5..Shaft.and.wheel.assembly.preparation:

a..Clean. protective. coating. off. shaft. with. solvent.. Do..

not.touch.clean.areas.of.shaft.with.hands..Perspiration.

can.cause.rust.or.pitting.over.time.

b..Remove.keys.from.shaft.

c..Clean.inside.of.wheel.bore.with.solvent..Make.sure.

setscrews.will.not.interfere.when.inserting.shaft.into.

wheel.bore.

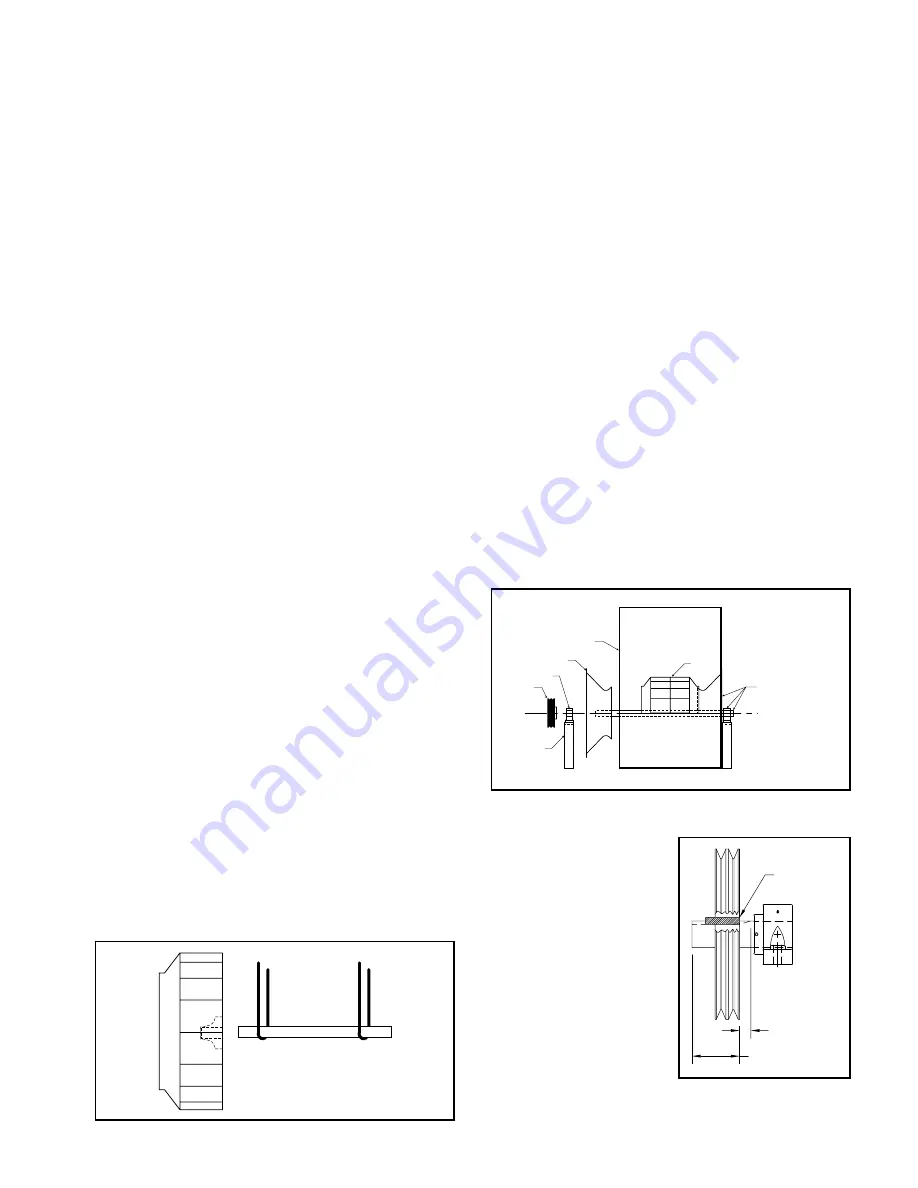

6..Arrangement. 1,. 9. or. 10:. Drive. Component. Assembly.

(See.Figure.3):

a..Insert.shaft.into.wheel.from.back.side.of.wheel.

b..When. shaft. is. flush. with. wheel. hub,. put. key. into..

keyway.and.tighten.wheel.setscrews.

c..Insert. shaft. through. opening. in. drive. side.. (If. split.

housed.unit,.lower.into.position.)

d..Install. bearings. onto. shaft.. Do. not. tighten. bearing.

setscrews. at. this. time.. The. bearing. housing. should.

be.perpendicular.and.the.bearing.base.parallel.to.the.

axis.of.the.shaft.to.prevent.loads.caused.by.misalign-

ment.

e..Mount.assembly,.bolt.bearings.to.drive.stand..Shaft.

Figure 3. Drive Component Assembly

must. be. parallel. with. side. of. bearing. pedestal..

Precision. shim. bearings. as. required.. After. aligning.

and.bolting.bearings.to.pedestal,.lock.bearings..Be.

sure. expansion. bearing. (if. supplied). is. set. to. allow.

for.growth..Continue.with.step.8.

7..Arrangement.3.(Split-housed).units.(See.Figure.4):

a..Parts.on.DWDI.units.are.assembled.in.the.following.

order. as. viewed. from. opposite. drive. side:. Bearing.

bar. assembly. and. opposite. bearing,. funnel,. (hous-

ing. side),. wheel,. (housing. side),. funnel,. drive. side.

bearing. bar. assembly,. drive. bearing. and. sheaves..

Mount. bearing. bar. assembly. to. housing.. Center.

wheel.in.funnels.

b..Parts.on.SWSI.units.are.assembled.in.the.following.

order. as. viewed. from. opposite. drive. side:. Bearing.

bar.assembly.and.opposite.bearing,.funnel,.(housing.

side),. wheel,. (housing. side),. drive. side. bearing. bar.

assembly,.drive.bearing.and.sheaves..Mount.bearing.

bar. assembly. to. housing.. (See. Figure. 7. for. wheel-

funnel.overlap.)

c..Assemble.parts.in.above.order.on.shaft.

d.. Move. assembly. into. position.. Lightly. bolt. bearings.

into.place.

e.. Shaft. should. be. parallel. with. discharge. of. housing..

Move.bearings.to.accommodate.

f... Level.shaft;.shim.bearings.if.required..Lock.bearings..

Be.sure.expansion.bearing.(if.supplied).is.set.to.allow.

for.shaft.growth.

8..Install. motor. on. base.. Carefully. align. shafts. for. drive.

installation.

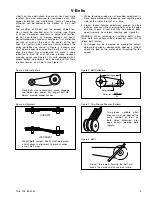

9..Mount.drives.as.follows:

a..Slip.(do.not.pound).

proper.sheave.

onto.correspond-

ing.shaft..CAUTION:.

PLACING.FAN.

SHEAVE.ON.MOTOR.

CAN.OVERSPEED.

WHEEL.AND.CAUSE.

STRUCTURAL.

FAILURE.

b..Position.

sheaves.

so. they. are. placed.

on. motor. shaft. and.

fan. shaft. as. close.

as. possible. to. the.

motor. and/or. bear-

ing.. Sheave. must. be.

placed. so. that. it. does. not. rub. on. the. bearing,.

motor.guard.or.other.structures..On.keyed.shafts,.

Shaft

Centerline

Bearing

Pedestal

Sheave

Bearing

Inlet Funnel

Housing Side

Wheel

Assembled Bearing,

Shaft, Funnel, and

Housing. Frame

Angles Not Shown.

Figure 4. Split-housed Drive Component Assembly

SHEAVE LINED

UP WITH END

OF KEYWAY

RUN OUT

RUN OUT OF

KEYWAY

KEYWAY LENGTH

Figure 5. Sheave Position