Twin City Engineering Supplement ES-52

7

bearings.with.split.pillow.block.housings..Observation.of.

the. condition. of. the. grease. expelled. from. unit. ball. or.

roller. bearings. at. the. time. of. relubrication. is. the. best.

guide.as.to.whether.regreasing.intervals.and.the.amount.

of.grease.added.should.be.altered..This.observation.is.

particularly.important.when.bearings.operate.continuous-

ly.over.160°F..Spherical.roller.bearings.with.split.pillow.

block.housing.should.be.lubricated.until.grease.purges.

or.overheating.may.result..Follow.the.lubrication.interval.

and.amount.noted.in.Figure.11..Spherical.roller.bearings.

with.split.pillow.block.housings.should.be.serviced.once.

per.year..Remove.cap,.clean.out.old.grease.and.replace,.

filling.the.bottom.half.of.the.housing.1/3.full.

. Greases. are. made. with. different. bases.. There. are.

synthetic.base.greases,.lithium.base,.sodium.base,.etc..

Avoid.mixing.greases.with.different.bases..They.could.be.

incompatible.and.result.in.rapid.deterioration.or.break-

down.of.the.grease.

. All.bearings.are.filled.with.grease.before.leaving.the.

factory.. When. the. fans. are. started,. the. bearings. may.

discharge. excess. grease. through. the. seals. for. a. short.

period. of. time.. Do. not. replace. the. initial. discharge.

because.leakage.will.cease.when.the.excess.grease.has.

worked.out..Sometimes.the.bearing.has.a.tendency.to.

run. hotter. during. this. period. and. one. should. not. get.

alarmed. unless. it. lasts. over. 48. hours. or. gets. above.

220ºF.. When. relubricating,. use. a. sufficient. amount. of.

grease.to.purge.the.seals..Rotate.bearings.during.relu-

brication.where.good.safety.practice.permits.

. For.bearings.with.oil.lubrication,.sight.gauges.are.installed.

so. that. a. proper. level. can. be. reviewed. and. maintained..

Sight.gauges.should.be.read.with.bearings.not.rotating.

Wheel and Shaft Maintenance

Periodically.inspect.the.shaft.and.wheel.for.dirt.buildup,.

corrosion,.and.signs.of.excess.stress.or.fatigue..Clean.

the.components.and,.when.appropriate,.apply.new.coat-

ings.. (Any. addition. of. coatings. or. weld. can. create. an.

imbalance.).Check.the.balance.of.the.assembly.

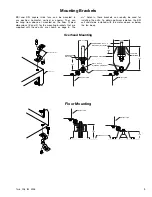

Structural Maintenance

All.structural.components.or.devices.used.to.support.or.

attach.the.fan.to.a.structure.should.be.checked.at.regu-

lar.intervals..Vibration.isolators,.bolts,.foundations,.etc.,.

are.subject.to.failure.from.corrosion,.erosion,.and.other.

causes..Improper.mounting.can.lead.to.poor.operation.

characteristics.or.fan.fatigue.and.failure.

. Check.metallic.components.for.corrosion,.cracks,.or.

other. signs. of. stress.. Concrete. should. be. checked. to.

ensure.the.structural.integrity.of.the.foundation.

Troubleshooting Guidelines

Use. current. safety. practices. when. investigating. fan. or.

system. performance. problems.. General. safe. practices.

and. performance. troubleshooting. guidelines. can. be.

found.in.AMCA.Publications.410.and.202,.respectively..

Fan. application.and. field.measurement.procedures.can.

be.found.in.AMCA.Publications.201.and.203.

Troubleshooting Performance Problems

The.lists.below.indicate.possible.areas.to.check.when.air.

or.sound.values.do.not.match.expectations..Most.fan.prob-

lems.can.be.pinpointed.to.one.of.these.common.causes.

Air Capacity Problems:

1..Resistance. of. system. not. at. design. rating.. If. resis-

tance. is. lower. than. expected,. both. airflow. and.

horsepower. may. be. up.. If. resistance. is. higher. than.

anticipated,.air.volume.will.be.down.

2..Fan.speed.is.not.at.design.speed.

3..Air.density.not.at.design.values..Also.check.air.per-

formance.measurement.techniques/procedures.

4..Devices. for. air. modulation. are. closed. or. plugged..

Also.check.filters.

5..Wheel.mounted.improperly.or.is.rotating.in.reverse..

6..Parts.of.system.or.fan.have.been.damaged.or.need.

cleaning.

Noise Problems:

1..Air.performance.is.incorrect.and.fan.is.not.at.design.

point. of. operation.. Fan. forced. to. operate. in. an.

unstable.flow.region.

2..Bearing.failure..Check.bearings.(lubrication).

3..Supply.voltage.high.or.inconsistent.supply.frequency..

Adjustable. frequency. controllers. can. generate. motor.

noise.

4..Objects. which. are. installed. in. a. high. velocity. air-

stream. can. generate. noise.. This. includes. flow. sen-

sors,.turning.vanes,.etc.

5..Poor.fan.inlet.conditions.

6..Acoustics.or.sound.measurement.procedure.incorrect.

Vibration Problems:

1..Misalignment.of.drive.components.

2..Poor.foundations.or.mounting.structure.(resonances).

3..Foreign.material.attached.to.rotating.components.

4..Damaged. rotating. components. (bearings,. shaft,. fan,.

wheel,.sheaves).

5..Broken,.loose.or.missing.setscrews.

6..Loose.bolts..

7..Vibration.transmitted.by.another.source.

8..Water.accumulating.in.airfoil.blades.

9..Fan.is.operating.in.stall.or.unstable.flow.region.

NOTE:

. All. fans. manufactured. by. Twin. City. Fan. &.

Blower.are.factory.balanced.prior.to.shipment..Handling.

and. movement. of. the. fan. during. shipment. may. cause.

the. rotating. assembly. to. shift.. Balance. should. be.

checked.once.the.fan.is.installed..If.a.final.trim.balance.

is.required,.it.is.the.end.user's.responsibility.to.bring.the.

fan.back.to.factory.specifications..Final.trim.balancing.is.

not.the.responsibility.of.Twin.City.Fan.&.Blower..Refer.

to.Figure.12.for.vibration.guidelines.

Motor Problems:

1..Incorrect.wiring.

2..Speed.of.fan.too.high.

3..Parts.improperly.installed.-.binding.

4..Bearings.improperly.lubricated.

5..WR

2

.capability.of.motor.too.low.for.application.

6..Protection.devices.may.be.improperly.sized.

Drive Problems:

1..Belts.improperly.tensioned.

2..Drive.alignment.is.poor.

Condition

Fan

Application

Category

Rigidly Mounted

mm/s (in./s)

Flexibly Mounted

mm/s (in./s)

Start-up

BV-3

6.4.(0.25)

8.8.(0.35)

BV-4

4.1.(0.16)

6.4.(0.25)

Alarm

BV-3

10.2.(0.40)

16.5.(0.65)

BV-4

6.4.(0.25)

10.2.(0.40)

Shutdown

BV-3

12.7.(0.50)

17.8.(0.70)

BV-4

10.2.(0.40)

15.2.(0.60)

Figure 12. Vibration Guidelines

Value.shown.are.peak.velocity,.mm/s.(inches/s),.Filter.out.

Table.taken.from.ANSI/AMCA.Standard.204-05,.Table.6.3..

AMCA.defines.BV-3.for.applications.up.to.400.HP;.BV-4.for.applica-

tions.over.400.HP.