Twin City IM-4050

7

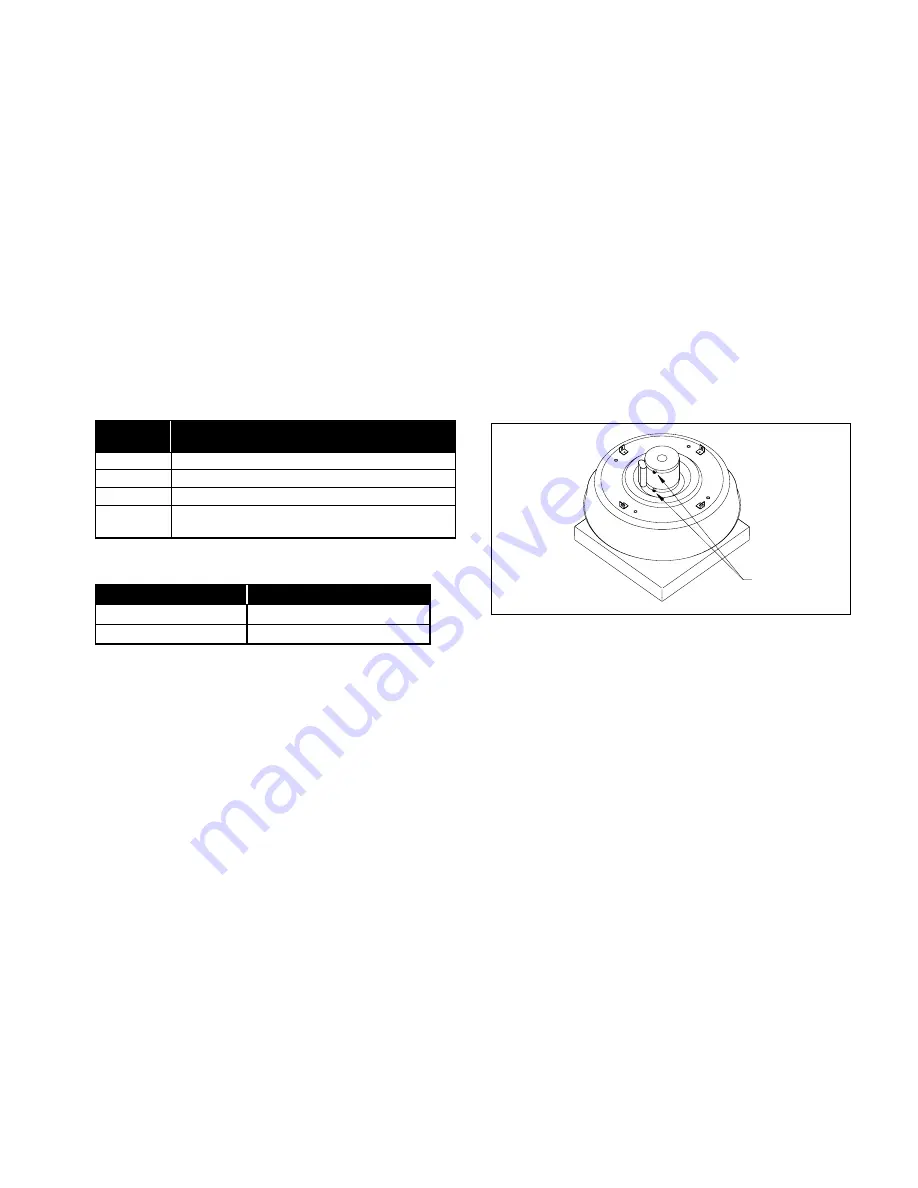

OIL TUBES

Figure 10. Sleeve Bearing Motor Oil Tube Location

Storage

If fans are stored for any length of time, they should be stored in a clean, dry location to prevent rust and corro-

sion. Outdoor storage is not recommended. When outdoor storage is necessary, fans should be protected from the

elements as completely as possible. Cover the fan inlet and outlet and keep motors dry and clean.

For extended storage (more than 3 months) motor shafts and bearings should be rotated monthly. If stored longer

than 6 months, bearing grease in motor and fan should be purged and replaced with compatible grease. Belts should

be rechecked for proper tension. Storage records should be kept to assure proper maintenance. The factory can

advise warranty centers to provide motor and bearing service if needed.

Table 5. Suggested Fan Bearing Greasing Intervals

INTERVAL

TYPE OF SERVICE

(MONTHS)

12 to 18

Infrequent operation or light duty in clean atmosphere.

6 to 12

8 to 16 hrs./day in clean, relatively dry atmosphere.

3 to 6

12 to 24 hrs./day, heavy duty, or if moisture is present.

1 to 3

Heavy duty in dirty, dusty locations; high ambient

temperatures; moisture laden atmosphere; vibration.

Table 6. Grease Manufacturers

MANUFACTURER

GREASE (NLGI #2)

Shell

Gadus S2 V100 2 or equivalent

Exxon/Mobil

Ronex MP

12. The standard pillow block bearings on belt driven

ventilators are factory lubricated and are provided with

external grease fittings. Lubrication annually is recom-

mended, or more frequently if needed (see Table 5).

It is recommended to add fresh grease at start-

up, but do not over-grease. Use only 1 or 2 shots

of a recommended lubricant with a hand gun in

most cases (see Table 6). Maximum hand gun rating

40 P.S.I. Rotate bearings during lubrication where

good safety practice permits.

CAUTION:

Greases of different soap bases

(lithium, sodium, etc.) may not be compatible when

mixed. Prevent such intermixing by completely purg-

ing the bearing of old greases.

The most frequent causes of bearing failure are

not greasing often enough, using an excessive

quantity of grease, or using incompatible greases.

Excessive vibration, especially if the bearing is not

rotating, will also cause bearings to fail. Bearings

must also be protected from water and moisture to

avoid internal corrosion.

13. During the first few months of operation it is rec-

ommended that the bearing setscrews be checked

periodically to ensure that they are tight.

14. The rotating wheel requires particular attention since

materials in the air being handled can build up on

the blades to cause destructive vibration or weaken

the structure of the wheel by corroding and/or erod-

ing the blade metal. Regular inspection and correc-

tive action at intervals determined by the severity of

each application are essential to good service life

and safety.

Motor Lubrication

Motors which contain ball bearings are permanently

lubricated from the factory. No additional maintenance

is required.

Motors which contain sleeve bearings require lubrication

every six (6) months. Use SAE-20W lubricant and add

five (5) drops to each location shown in Figure 10. DO

NOT OVER LUBRICATE.