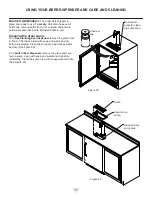

8

"A"

"B"

"C"

"D"

"D"

"E"

"E"

"H"

"G"

"F"

"J"

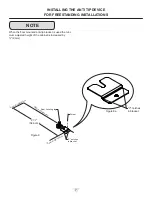

If necessary to gain clearance inside the rough-in

opening a hole can be cut through the adjacent cabi-

net and the power cord routed through this hole to a

power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this applica-

tion as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application, (see Figure 11).

Figure 11

ROUGH-IN OPENING DIMENSIONS

CABINET DIMENSIONS

MODEL

"A"

"B"

"C"

"D"

"E"

"F"

"G"

"H"

"J"

TEBK24-F

TEBK242-F

24"

(61 cm)

**34" to 35"

(86.4 to 88.9 cm)

*

23

7

⁄

8

"

(60.7 cm)

33

3

⁄

4

" to 34

3

⁄

4

"

(85.7 to 88.3 cm)

23

23

⁄

32

"

(60.2 cm)

26

5

⁄

16

"

(66.8 cm)

46

13

⁄

32

"

(117.9 cm)

26

5

⁄

16

"

(66.8 cm)

PRODUCT DATA

MODEL

ELECTRICAL

REQUIREMENTS#

PRODUCT

WEIGHT

TEBK24-F

TEBK242-F

115V/60Hz/15A

140 lbs

(63.6 kg)

Figure 10

21

1

⁄

2

"

(54.6 cm)

12

1

⁄

4

"

(31.1 cm)

11

15

⁄

16

"

(30.3 cm)

11"

(27.9 cm)

Figure 9

* Depth dimension of rough-in opening may vary depend-

ing on each individual installation. To recess entire door "F"

dimension plus 1" (2.5 cm) for thickness of power cord plug

is required.

** Minimum rough-in opening required is to be larger than

the adjusted height of the cabinet.

# A grounded 15 amp dedicated circuit is required. Follow

all local building codes when installing electrical and appli-

ance.

PRODUCT DIMENSIONS

Figure 9a