12

If you want to stop the boiler for a longer period then you MUST empty the burner tube

from glows to avoid a burn-back into the fuel store.

The risk of burn-back is varying from one fuel to the next. Wood chips are more likely to

cause back-burn than grains or pellets. The glows might due out by the selves, but you

cannot be sure, this happens

If the boiler is stopped e.g. during summer, then please open the combustion room

door to prevent moisture from condensing in boiler or chimney.

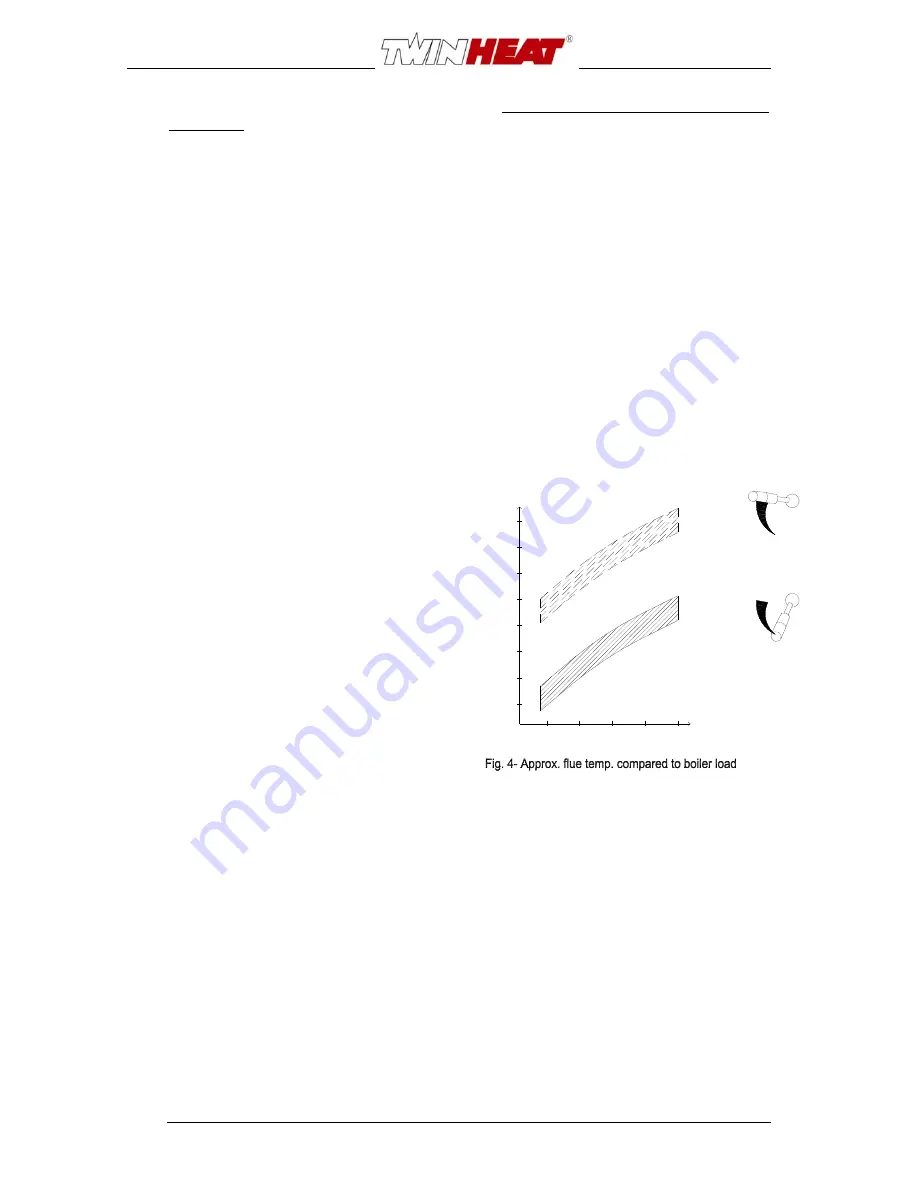

2.8 Bypass (flue temperature damper)

The very effective flue cooling in the boiler means that the flue is only 140 – 150 ºC by

100% load, when leaving the flue outlet. The flue temperature is closely connected to

the boiler output, means lower load = lower flue temp.

The handle on top of the boiler (the bypass) is used to adapt the flue temperature in

relation to boiler output. By fully opened damper only a part of the flue is passing the

flue cooler. By fully closed damper the flue is cooled to maximum (see fig 4)

Section 2 – Start up and normal use

If the boiler load is less than 40 – 50 %,

as is the case in large parts of the year,

you should open the bypass to increase

flue temperature, that the flue does not

condense on its way up through the

chimney. If in doubt about how to place

the damper, please consult your

installer.

(see section 2.6, pause)

20

40

60

80

80

100

120

140

100

160

180

200

220

Flue temp. °C

Open Bypass

Closed Bypass

Boiler load %