2.2. SUPPLY CONDITIONS AND DISPOSAL OF PACKINGS

HE CUTTING MACHINE IS PACKED IN A STURDY CARDBOARD BOX WITH

HE EQUIPMENT INCLUDE:

AND MAINTENANCE

COMPONENTS (CARTON, FOAM, STRAPS, AND SO ON) CAN

3. INSTALLATION

T

INTERNAL SHAPED EDGES WHICH GUARANTEE THE PERFECT INTEGRITY OF THE

MACHINE DURING TRANSPORT.

T

g

INSTRUCTIONS FOR USE

g

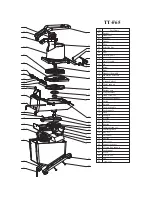

EJECTING DISC

ALL THE PACKING

EASILY BE DISPOSED OF AS HOUSEHOLD RUBBISH

3.1. SETTING THE MACHINE

HE MACHINE CONNECTION AND THE SETTING AT WORK MUST BE MADE BY

T

SKILLED PERSONNEL.

WARNING

: BOTH THE SYSTEM AND LOCATION WHERE THE EQUIPMENT HAS TO BE

RESPONSIBILITY FOR DIRECT

ED, DRY AND FIXED FACE, FAR FROM

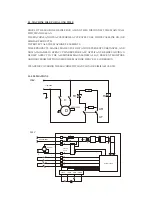

.2. ELECTRIC CONNECTIONS

SET MUST COMPLY WITH THE REGULATIONS FOR THE ACCIDENT PREVENTION

AND ELECTRICAL REGULATIONS IN FORCE.

THE MANUFACTURER DECLINES ANY AND ALL

OR INDIRECT DAMAGES WHICH MAY ENSUE FOR NON-COMPLIANCE WITH

THE ABOVE MENTIONED REGULATIONS.

SET THE EQUIPMENT ON A WIDE, LEVELL

HEAT SOURCES AND WATER SPRAYS.

3

HE EQUIPMENT IS SUPPLIED WITH AN ELECTRIC CABLE TO BE CONNECTED TO A

HE

HE MANUFACTURER DECLINES ANY AND ALL RESPONSIBILITY FOR DIRECT AND

MANUFACTURED INTO SINGLE-PHASE V.220/1/50 HZ OR

T

MAGNETO-THERMIC MAIN SWITCH WHICH STOPS THE MACHINE WHEN THE

OPERATOR COMES IN FORTUITOUS CONTACT WITH THE ROTATING ELEMENTS.

IT IS IMPERATIVE THAT THE EQUIPMENT IS WELL GROUNDED ACCORDING TO T

REGULATIONS IN FORCE.

T

INDIRECT DAMAGES WHICH MAY ENSUE FOR NON-COMPLIANCE WITH THE

REGULATIONS IN FORCE.

THE CUTTING MACHINE IS

V.115/1/60HZ. WHENEVER THE VOLTAGE DIFFERS FROM THE ABOVE MENTIONED,

PLEASE APPLY TO THE MANUFACTURER, OR THE AUTHORIZED DISTRIBUTOR.