409-10016

ELT Machine 1338600-[

Rev H

10 of 34

Tyco Electronics Corporation

Install the lift ring carefully. A 19.05-mm [.75-in.] thread length engagement is required for the lift ring to support the

machine.

Attach a suitable hoist to the lift ring, lift the machine, and place it in the selected operating location.

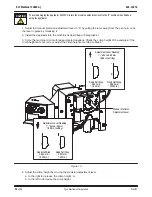

Insert the reel support post into the appropriate hole on top of the machine (Figure 7) until the roll pin engages

a groove in the machine frame.

Attach the terminal strip guide included with the machine with the two thumbscrews supplied. Mount the guide

on the left guard for side–feed applicators. Mount the guide on the right guard for end–feed applicators.

Connect the power cord to a suitable electrical supply.

The machine will automatically detect the supply voltage and adjust the controller accordingly.

Machines exported to Europe will be installed by Tyco Electronics service engineers. These engineers will verify that

the electrical and pneumatic connections are correct. Both pneumatic and electrical connections must be installed in a

way that provides a lockable isolation switch for hard-wired or direct piped machines. This is necessary to interrupt

power to the machine for setup or maintenance.

3.3. Considerations Affecting Placement of BenchMachines

The location of the machine in relation to the operator’s position is extremely important in terms of both safety

and maximum efficiency. Studies have repeatedly shown that operator fatigue will be reduced, and greater

efficiency achieved, if:

1. the bench is of appropriate height, preferably with sound–deadening rubber mounts;

2. the machine is properly located on the bench with ample work areas on both sides to facilitate work

flow;

3. the operator uses a swivel chair with padded seat and back rest which are independently adjustable;

and

4. the foot switch, on machines so equipped, is placed on a rubber mat to maintain its movability, while

preventing it from sliding unintentionally.

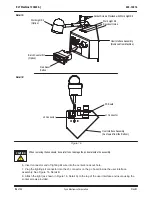

Figure 9 illustrates proper machine location and operator position and the following:

A.

Bench

The bench to be used should be of sturdy construction, preferably with rubber mounts to minimize noise. A

height of 762 to 812.8 mm [30 to 32 in.] is the most suitable for operator comfort and convenience. This

height allows the operator to rest both feet on the floor, thereby providing for the shifting of weight and leg

position.

B.

Machine Location on Bench

The machine should be located near the front of the bench with the “target area” (tooling area where the

product is applied) not more than 152.4 to 203.2 mm [6 to 8 in.] from the front edge. This location will

eliminate unnecessary operator motion and help to avoid back strain and fatigue.

Orientation of the machine should be such that the “target area” is facing the front of the bench and is

parallel to the front edge (access to the back of the machine MUST also be provided).

Machines have provisions for being bolted to the bench.

C.

Operator's Chair

The operator’s chair should swivel, and should have independent seat height and back rest adjustments.

The seat and back rest should be padded, and the back rest should be large enough to provide support

both above and below the waist line.

CAUTION

!

NOTE

i

NOTE

i

NOTE

i