409-10016

ELT Machine 1338600-[

Rev H

18 of 34

Tyco Electronics Corporation

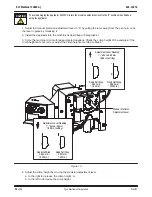

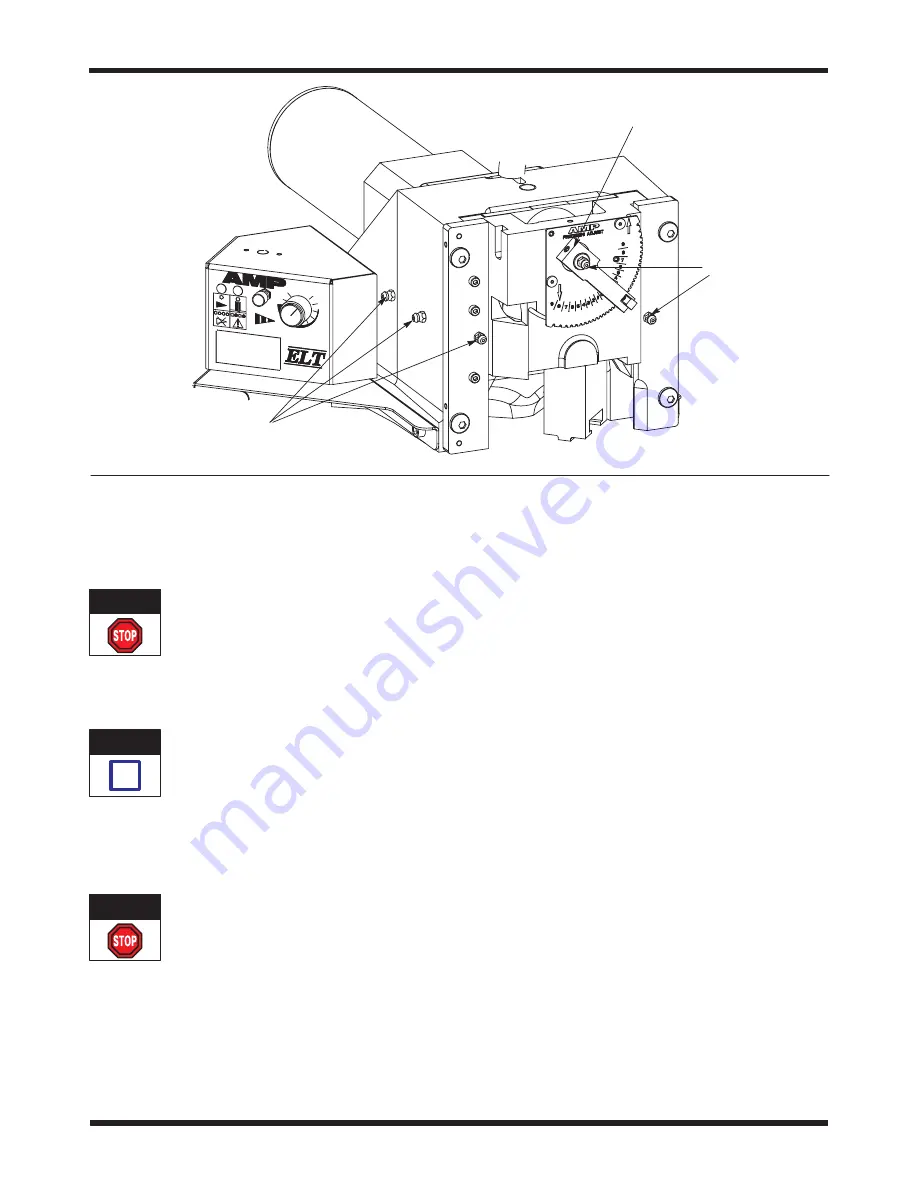

Figure 12

Lubrication Points

Lubrication Points

Shown with Optional Precision Crimp

Height Adjustment Mechanism

6. ADJUSTMENTS

The following adjustments are necessary to maintain the machine in operating condition, and to set up the

machine after replacing parts.

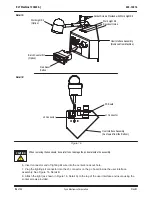

To avoid personal injury, ALWAYS disconnect electrical and air supplies before performing adjustments.

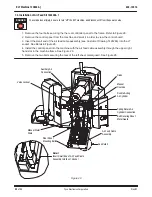

6.1. Measuring the Shut Height

The shut height is the distance between the bottom surface of the ram post adaptor and the top surface of the

machine base plate as shown in Figure 13.

Shut Height Gage 679655-2 is recommended for measuring shut height (refer to 408-8535 for instructions on use of

the gage).

1. If installed, adjust the manual precision adjustment lever to the “0” setting.

2. Remove the access cover (Figure 7) on the end of the motor.

3. Insert a 6–mm hex wrench into the end of the motor until it completely engages the hex key in the

end of the motor. Use the hex wrench to manually rotate the motor.

Be sure to remove the hex wrench before operating the machine.

4. Follow the procedure for measuring the shut height as described in 408–8535.

5. Install the access cover onto the end of the motor.

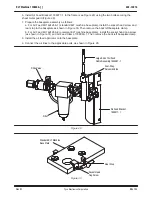

6.2. Shut-Height Adjustment

The shut height is pre–set at the factory and should not require further adjustment unless it is necessary to

replace parts. Before you make any changes to the machine, contact your local Field Service Engineer, or call

the Tooling Assistance Center at 1–800–722–1111.

DANGER

NOTE

i

DANGER