408-8473

Universal Rack Mount Enclosure 1435040-1

Rev A

2 of 5

Tyco Electronics Corporation

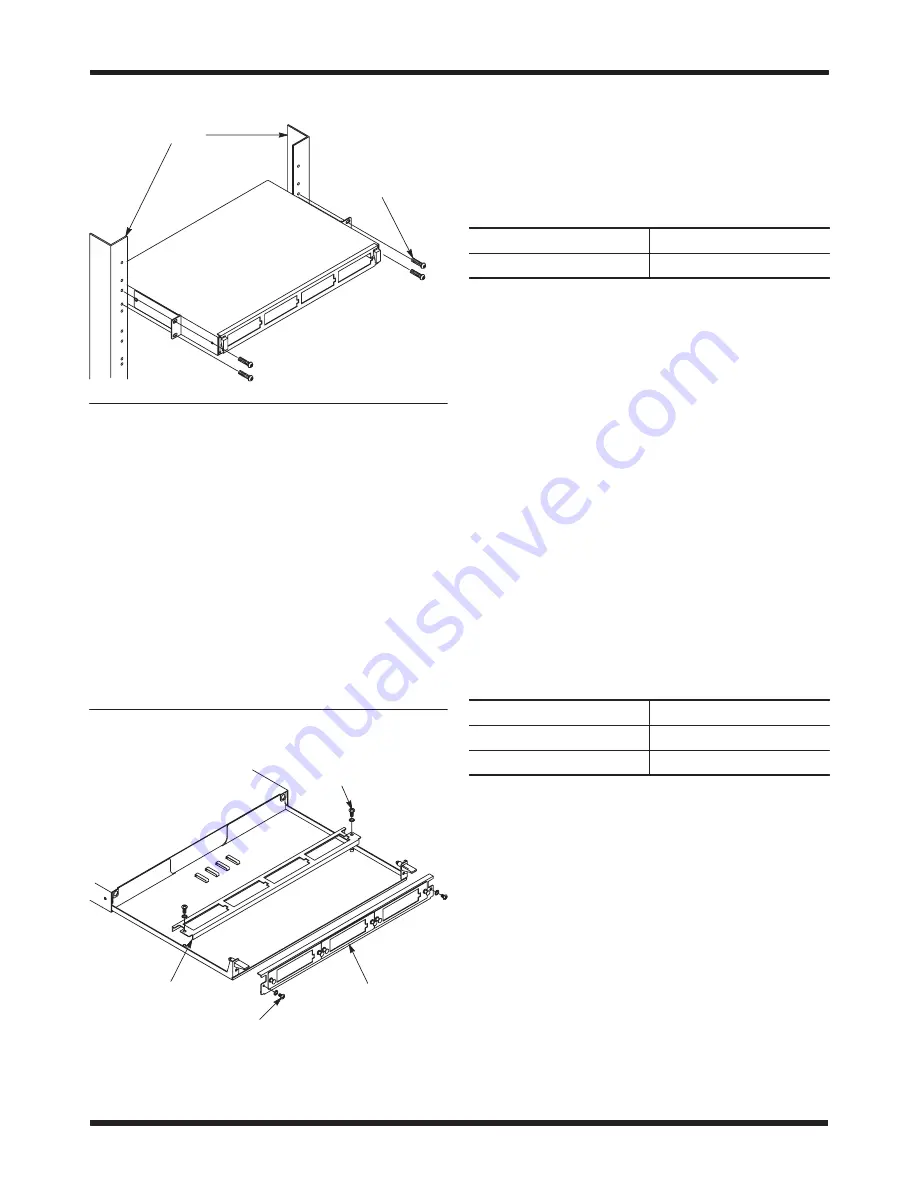

Figure 2

Mounting the Enclosure

Rack

Front of

Enclosure

Pan Head Screw

(4 Places)

3.2. Install the Faceplate

If the faceplate required for your application is not

installed onto the front of the tray, refer to Figure 3,

and proceed as follows:

1. Unscrew the two screws securing the faceplate

onto the base of the tray. Lift the faceplate away

from the tray. Retain these long screws and the

washers.

2. Unscrew the two screws securing the faceplate

onto the front of the tray. Pull the faceplate away

from the tray. Retain these short screws and the

washers.

Figure 3

Installing the Faceplate

Long Screw and

Washer (2 Places)

Short Screw and

Washer (2 Places)

4-Position

Faceplate

3-Position

Faceplate

3. Secure the faceplate to be used onto the front of

the tray using the two short screws (and washers),

and secure the other faceplate onto the base of the

tray using the two long screws (and washers).

DO NOT OVER–TIGHTEN the screws.

3.3. Install Accessories

A. Cassette

APPLICATION

FACEPLATE

UTP Fiber/OpticalFiber

3-Position

To install a cassette, proceed as follows:

1. Choose the opening (position) in the faceplate to

install the cassette. Pull the lock pins of the

adapter plate until the adapter plate releases from

the faceplate. See Figure 4, Detail A. Retain the

adapter plate.

If necessary, to install an adapter plate onto the

faceplate, refer to Paragraph 4.1.

2. Position the cassette over the front of the

opening in the faceplate. Orient the cassette so

that the split end of the lock pins align with the

holes in the faceplate and the network connectors

(connectors at the back of the cassette) face the

cutout in the tray. Feed the cassette through the

opening, and push the lock pins into the holes until

the cassette is flat against the faceplate and

secure (there will be an audible “click”). See Figure

4, Detail B.

If necessary, to remove a cassette from the

faceplate, refer to Paragraph 4.2.

B. PC Board Assembly or Adapter Block

APPLICATION

FACEPLATE

UTP Fiber/OpticalFiber

3-Position

UTP Fiber

4-Position

To install a pc board assembly or adapter block,

proceed as follows:

1. Choose the opening (position) in the faceplate to

install the patch panel or module. For the

3–position faceplate, the adapter plate must be

installed onto the faceplate. If necessary, to install

the adapter plate onto the faceplate, refer to

Paragraph 4.1.

2. If assembled, remove the pc board assembly

from the interface housing. Refer to Paragraph 4.3.

3. Install the interface housing according to the

following. Refer to Figure 5.

a. Position the interface housing over the back

of the opening in the faceplate. Orient the

housing so that the relief aligns with the notch in

the opening.