408–8547

CERTI–CRIMP II Straight Action Hand Tools

Rev B

4 of 4

4.5. CERTI–CRIMP Ratchet Inspection

The CERTI–CRIMP ratchet feature on these hand tools

should be checked to ensure that the ratchet does not

release prematurely, allowing the crimping dies to open

before they have fully bottomed. Obtain a 0.025–mm

[.001–in.] shim that is suitable for checking the clearance

between the bottoming surfaces of the crimping dies.

Proceed as follows:

1. Select the maximum size wire and strip it

according to dimensions listed in the drawing shipped

with the tool.

2. Select contact and crimp section corresponding to

the selected wire size (refer to the drawing shipped

with the tool).

3. Position the contact and wire in the crimping dies,

as described in the CRIMPING PROCEDURE

section.

4. Hold the wire in place and squeeze the handles

until the CERTI–CRIMP ratchet releases. Hold the

handles in this position, maintaining just enough

tension to keep the dies closed.

5. Check the clearance between the bottoming

surfaces of the wire crimper and the wire anvil. See

Figure 1. If the clearance is 0.025 mm [.001 in.] or

less (on at least two of the bottoming surfaces), the

ratchet is satisfactory. If clearance exceeds 0.025 mm

[.001 in.], the ratchet is out of adjustment and must be

repaired. See Section 5.

The insulation crimper does not bottom on the

insulation anvil

5. REPLACEMENT AND REPAIR

Replacement parts are listed in Figure 4. Parts other

than those listed in Figure 4 should be replaced by Tyco

Electronics to ensure quality and reliability of the tool.

Order replacement parts through your Tyco Electronics

representative, or call 1–800–526–5142, or refer to the

appropriate website:

S

toolrepair@tycoelectronics.com

S

asia.tool@tycoelectronics.com

S

jp_tool@tycoelectronics.com

S

uktoolingservicecentre@tycoelectronics.com

Tools may also be returned for evaluation and repair. For

tool repair service, contact a Tyco Electronics

representative at: 1–800–526–5136, or reference the

appropriate website above.

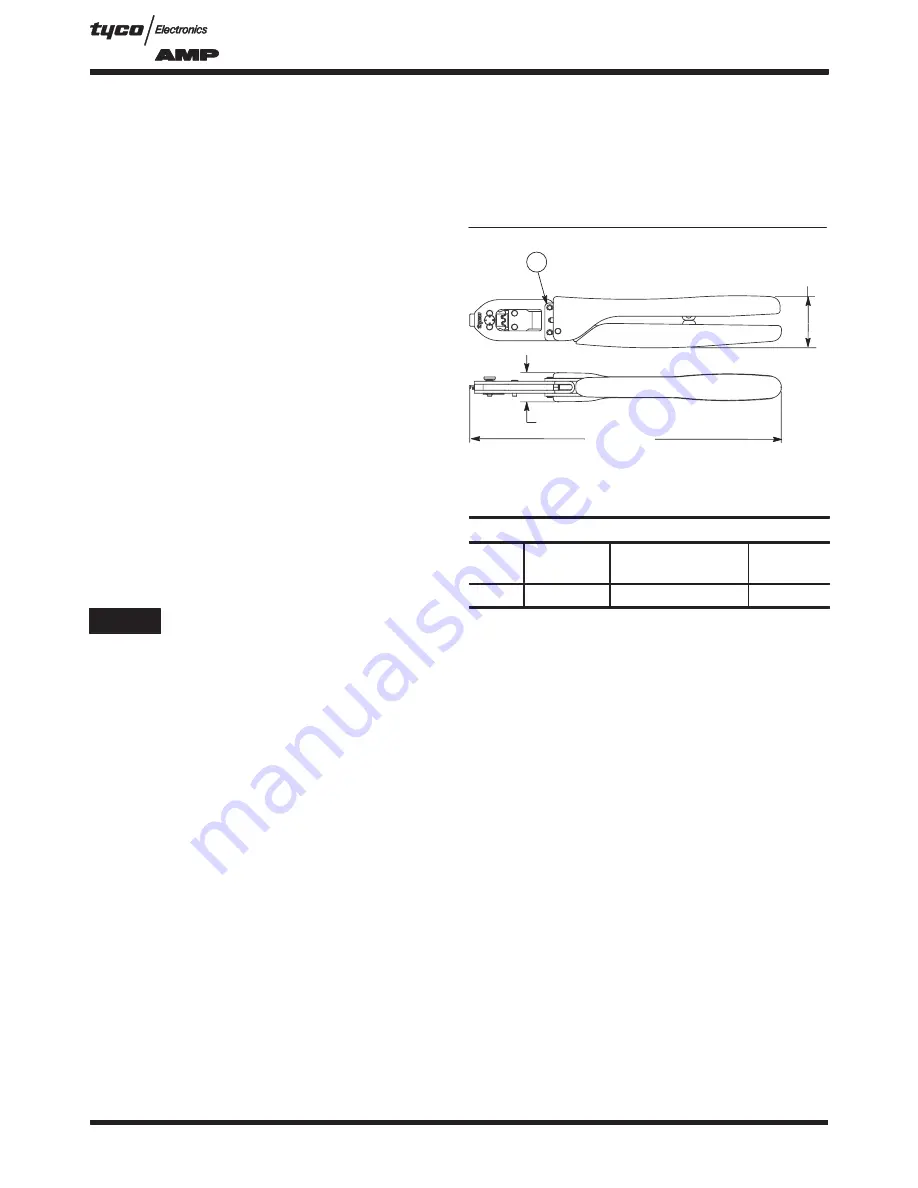

30 mm [1.2 In.]

303 mm

[11.9 In.]

52 mm

[2.1 In.]

(Closed)

1

Weight: Approx. 622.6 g [1 lb. 6 oz.]

REPLACEABLE PARTS

ITEM

PART

NUMBER

DESCRIPTION

QTY PER

TOOL

1

21045–3

RING, Retaining

4

Figure 4

6. REVISION SUMMARY

Per EC 0990–0449–02:

S

Revised website URL

S

Deleted second sentence in Section 1.,

INTRODUCTION

S

Updated format to current corporate requirements

NOTE