Instruction Sheet

408-78172

Rev. A

3 of 8

3. Instruction of cable connection and extraction

3-1 Cable Strip

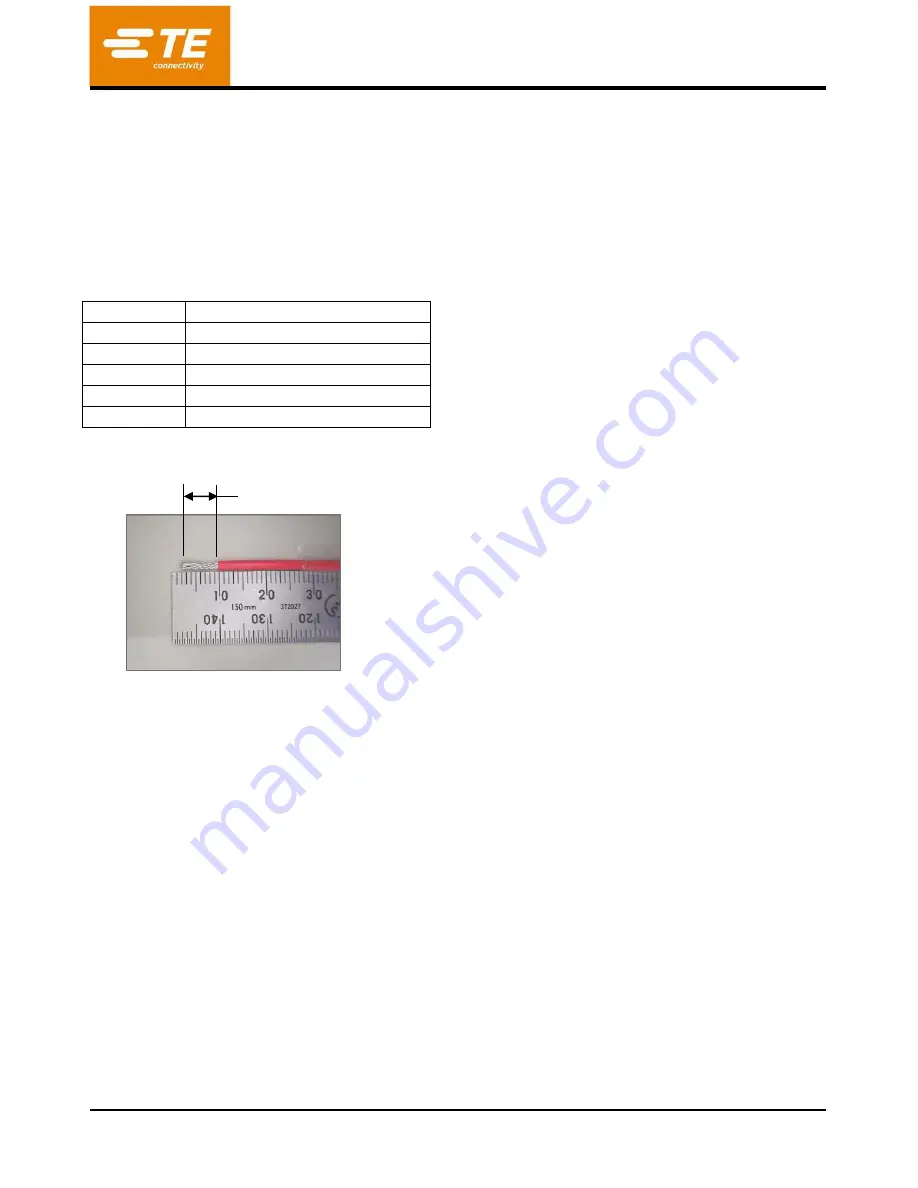

Use applicable size cable Fig2 . And strip the cable to 8±0.5mm. (Fig3)

If there is twist, bend or feazing. Please correct them. After correcting, check strip length. If there is

excessive deformation, do not use the cable.

Check the cut surface of conductor and insulation are flat.

AWG

Area of conductor [mm

2

]

AWG22

0.32

AWG20

0.52

AWG18

0.82

AWG16

1.3

AWG14

2.1

※

Insulation Diameter 3.8mm Max.

Fig. 2 Applicable Cable

Fig. 3 Strip Length

8

±

0.5