signed to NFPA 13D or NFPA 13R

are given in Table A as a function of

temperature rating and the maximum

allowable coverage areas. The single

sprinkler flow rate is the minimum re-

quired discharge from the most hy-

draulically demanding single sprin-

kler and, the multiple sprinkler flow

rate is the minimum required dis-

charge from each of the total

number of “design sprinklers” as

specified in NFPA 13D or NFPA 13R.

TIA 99-1 (Tentative Interim Amend-

ment) with an effective date of May

22, 2000 states that the minimum re-

quired discharge from each of the

“design sprinklers” for systems de-

signed to NFPA 13 must be calcu-

lated based on delivering a minimum

design density of 0.1 gpm/sq. ft. for

each of the listed coverage areas

shown in Table A. Consult with the

Authority Having Jurisdiction regard-

ing the application of this TIA to the

currently adopted NFPA 13.

For systems designed to NFPA 13,

13D, or 13R, consult with the local

authority having jurisdiction with re-

gard to the number of “design sprin-

klers” for sloped ceilings having a

slope greater than a 2 inch rise for a

12 inch run.

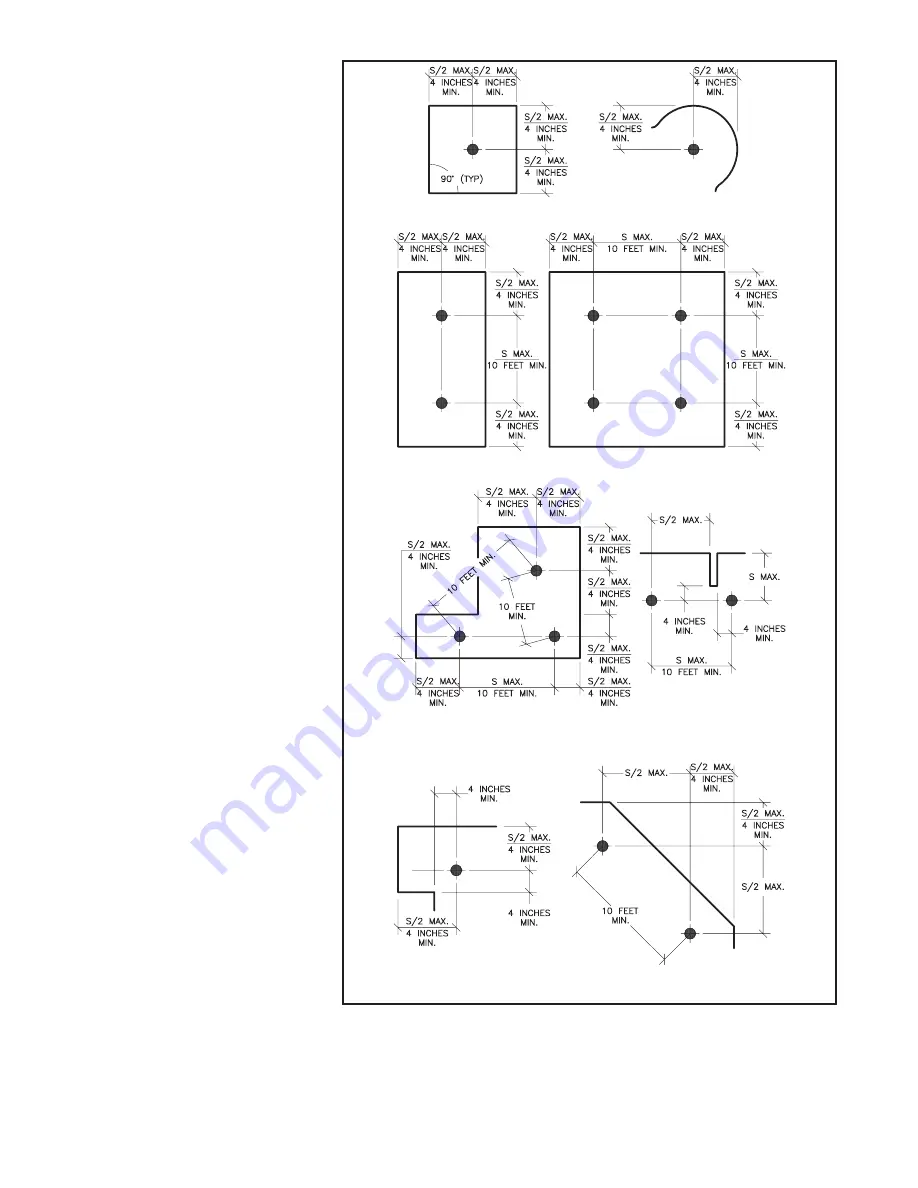

Spray Coverage Criteria.

Figure 2

and 3 provide spacing rules that

must be followed to assure that the

Model TFP1 Sprinklers will provide

their design distribution of water

spray.

Location of sprinklers with respect to

obstructions to water distribution are

to be in accordance with the obstruc-

tion rules for extended coverage pen-

dent sprinklers per the requirements

of NFPA 13.

Operational Sensitivity Criteria.

For proper operational sensitivity,

the Model TFP1 must be installed be-

neath a solid ceiling having a

smooth or textured surface.

The Model TFP1 must

NOT

be used

above or below open-gridded type

suspended ceilings; beneath soffits

or beams exceeding 3 inches in

height; or, with beams, joists, or

ducts having a height of more than 3

inches located within the sprinkler

coverage areas. Beams having a

height of more than 3 inches may be

located with their centerlines along

the boundaries separating adjacent

sprinkler coverage areas.

Cold Soldering Criteria.

Figures 2

and 3 provide the minimum spacing

requirements necessary for prevent-

ing the wetting (i.e., cold soldering)

of the heat responsive element of a

non-operated Model TFP1, which is

adjacent to one which has operated.

Heat Source Criteria.

Refer to

Figure 2-1 (Plan View)

Figure 2-2 (Plan View)

Figure 2-3 (Plan View)

Figure 2-4 (Plan View)

Figure 2-5 (Plan View)

Figure 2-6 (Plan View)

Figure 2-7 (Plan View)

Figure 2-8 (Plan View)

Figure 2

Spacing Rules Under Level Ceilings

S

=

THE LENGTH OF THE COVERAGE AREA BEING

HYDRAULICALLY CALCULATED (REF. TABLE A).

3

OBSOLETE