NFPA 13D or NFPA 13R for the re-

quirements relating to preventing the

possible release of a Model TFP1

heat responsive element, due to ex-

posure to heat sources other than

abnormal fire.

Installation

The Model TFP1 must be installed in

accordance with the following instruc-

tions:

NOTES

The Protective Cap is to remain

on the sprinkler during installa-

tion and until the ceiling installa-

tion is complete. The Protective

Cap must be removed to place the

sprinkler in service.

A leak tight 1/2 inch NPT sprinkler

joint should be obtained with a

torque of 7 to 14 ft.lbs. (9,5 to 19,0

Nm). A maximum of 21 ft.lbs. (28,5

Nm) of torque is to be used to in-

stall sprinklers. Higher levels of

torque may distort the sprinkler in-

let with consequent leakage or im-

pairment of the sprinkler.

Do not attempt to compensate for

insufficient adjustment in an Es-

cutcheon Plate by under- or over-

tightening the Sprinkler. Readjust

the position of the sprinkler fitting

to suit.

Step 1.

The Sprinkler must be in-

stalled only in the pendent position

and with the Sprinkler waterway cen-

terline perpendicular to the mounting

surface.

Step 2.

Install the sprinkler fitting so

that the distance from the face of the

fitting to the mounting surface will be

nominally 29/32 inches (23,0 mm) as

shown in Figure 1A.

Step 3.

With pipe thread sealant ap-

plied to the pipe threads, hand

tighten the Sprinkler into the sprin-

kler fitting.

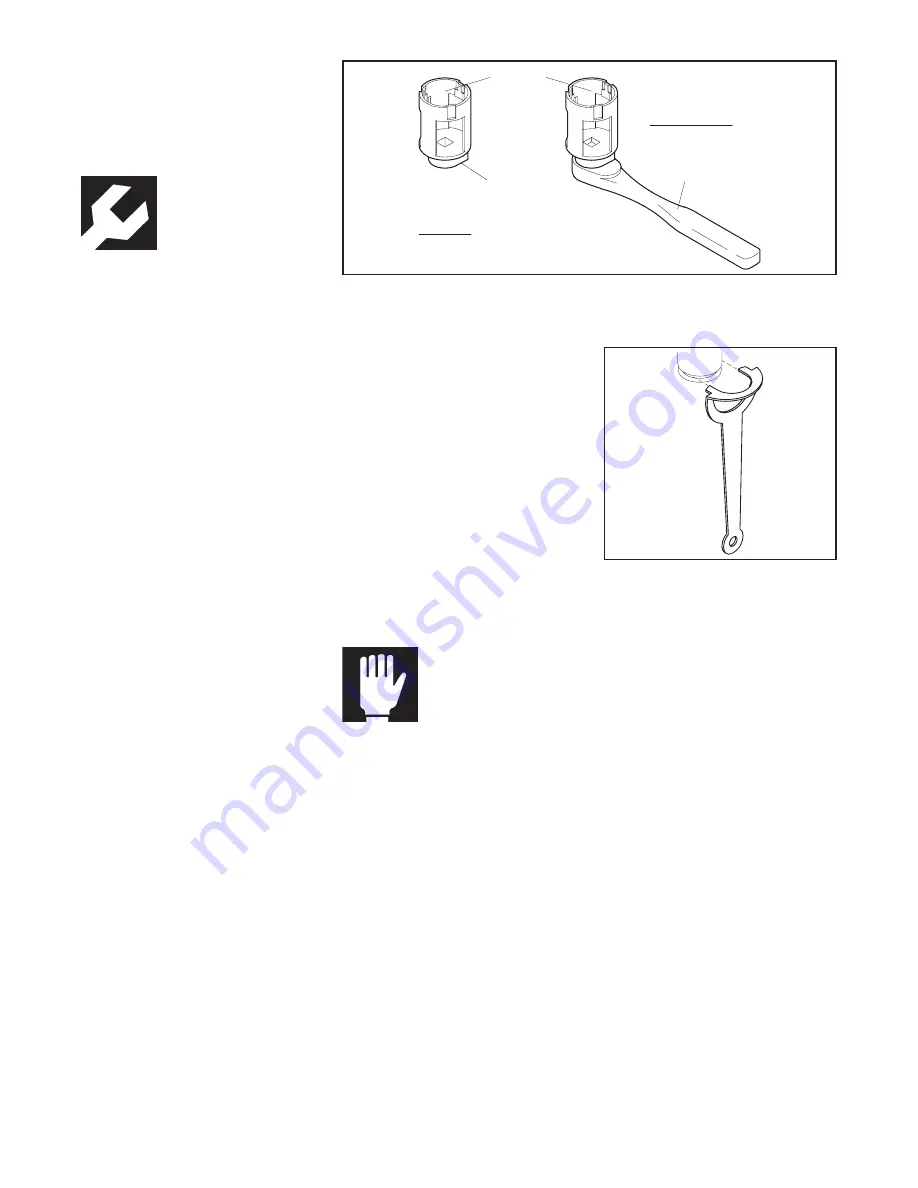

Step 4.

Wrench tighten the Sprinkler

using only the Sprinkler Socket or

Wrench & Socket Combination (Ref.

Figure 4). The wrench recess of the

Socket is to be applied to the sprin-

kler wrenching area (Ref. Figure 1A).

Step 5.

Use the “ceiling level toler-

ance limit” indicator on the Protec-

tive Cap to check for proper installa-

tion height. Relocate the sprinkler

fitting as necessary. If desired the

Protective Cap may also be used to

locate the center of the clearance

hole by gently pushing the ceiling

material against the center point of

the Cap.

Step 6.

After the ceiling has been

completed with the 2 inch (50 mm)

diameter clearance hole, use the

Protective Cap Removal Tool (Ref.

Figure 5) to remove the Protective

Cap and then push on the Escutch-

eon until its flange just comes in con-

tact with the ceiling. Do not continue

to push on the Escutcheon such that

it lifts a ceiling panel out of its nor-

mal position. If the Escutcheon can-

not be engaged with the Sprinkler, or

the the Escutcheon cannot be en-

gaged sufficiently to contact the ceil-

ing, relocate the sprinkler fitting as

necessary.

Care and

Maintenance

The Model TFP1 must be maintained

and serviced in accordance with the

following instructions:

NOTES

It is the responsibility of the in-

stalling contractor to provide a

copy of this document to the

owner or his representative, and

in turn, it is the obligation of the

owner to provide a copy of this

document to a succeeding owner.

Wet pipe sprinkler systems must

be maintained at a minimum tem-

perature of 40°F/4°C to prevent

freezing and bursting of the pipe

and/or sprinklers.

Automatic sprinklers are not to be

tested with a heat source. Opera-

tion of the heat responsive ele-

ment can result.

Absence of an Escutcheon Plate

may delay the time to sprinkler op-

eration in a fire situation.

Before closing a fire protection

system main control valve for

maintenance work on the fire pro-

tection system which it controls,

permission to shut down the af-

fected fire protection system must

be obtained from the proper

authorities and all personnel who

may be affected by this action

must be notified.

Do NOT enclose sprinklers within

drapes, curtains, or valances.

Do NOT hang anything from the

sprinklers.

Do NOT cleanse the sprinklers

with soap and water, detergents,

ammonia, cleaning fluids, or other

chemicals. Remove dust, lint, cob-

webs, cocoons, insects, and lar-

vae by gently brushing with a

feather duster or gently vacuum-

ing with a soft bristle (i.e., dust-

ing) brush attachment.

Exercise suitable safety precau-

tions in the use and storage of

highly flammable materials. The

rapid rate of fire development and

spread of which can be caused by

such materials can reduce the abil-

ity of the sprinkler system to aid

in the control of a fire in which

they are involved.

Figure 4

TFP1 Sprinkler Socket

TFP1 Wrench & Socket Combination

DRIVE

3/8" SOCKET

ACCEPTS

WRENCH

RECESS

WRENCH

COMBINATION

WRENCH & SOCKET

#4948

#4947

SOCKET

Figure 5

TFP1 Protective Cap

Removal Tool

5

OBSOLETE