TFP800

Page 3 of 6

Main Pipeline Strainers

Main pipeline strainers per NFPA 15 are

required for systems utilizing nozzles

with a flow path less than 3/8 in. (9,5

mm) diameter, that is, K=1.4 (Table A),

and for any system where the water is

likely to contain obstructive material.

Installation

The TYCO Type EA-1 PROTECTO-

SPRAY Directional Spray Nozzles

must be installed in accordance with

this section.

NOTICE

Do not install an Type EA-1 Nozzle if

the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 3/32 in.

(2,4 mm) for the 135°F (57°C) to 1/4 in.

(6,4 mm) for the 500°F (260°C) temper-

ature ratings.

Obtain a leak-tight 1/2 in. NPT nozzle

joint by applying a minimum-to-maxi-

mum torque of 7 to 14 ft-lb (9,5 to 19,0

N

∙

m). Higher levels of torque can distort

the nozzle inlet and cause leakage or

impairment of the nozzle.

Step 1.

With pipe-thread sealant

applied to the pipe threads, hand-

tighten the nozzle into the nozzle fitting.

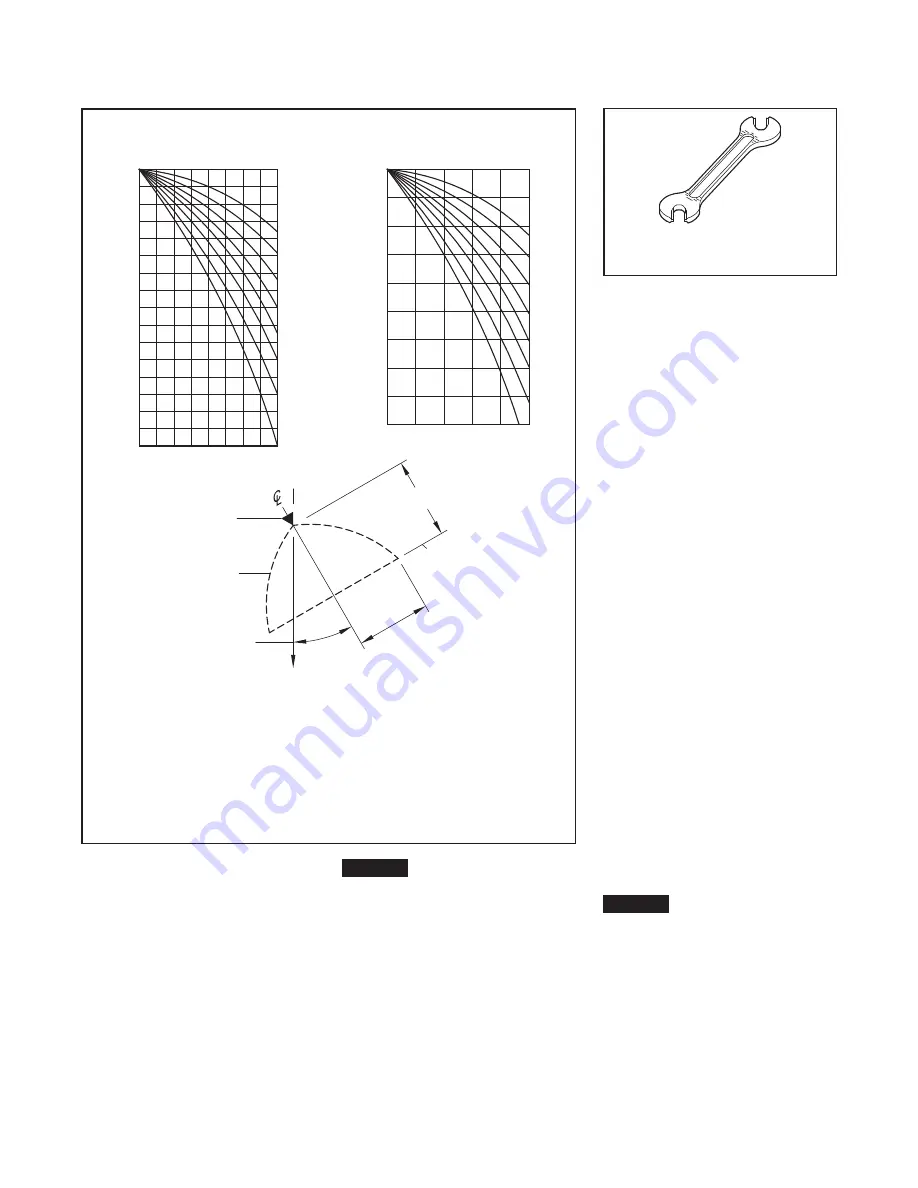

Step 2.

Tighten the nozzle into the

nozzle fitting using only the W-Type 11

Sprinkler Wrench (Figure 3), except that

an 8 in. or 10 in. adjustable crescent

wrench is to be used for wax-coated

nozzles. With reference to Figure 1,

the W-Type 11 Sprinkler Wrench or the

adjustable crescent wrench, as appli-

cable, is to be applied to the wrench-

ing area.

When installing wax-coated nozzles

with the adjustable crescent wrench,

exercise additional care to prevent

damage to the wax coating on the

nozzle wrenching area or frame

arms and, consequently, exposure of

bare metal to the corrosive environ-

ment. Sufficiently widen the jaws of

the wrench enough to pass over the

wrenching area without damaging the

wax coating. Before wrench-tighten-

ing the nozzle, adjust the jaws of the

wrench to contact the nozzle wrench-

ing area. After wrench-tightening the

nozzle, loosen the wrench jaws before

removing the wrench.

After installation, inspect the nozzle

wrenching area and frame arms and

retouch (repair) the wax coating wher-

ever the coating has been damaged

and bare metal is exposed. Retouch

the wax coating on the wrenching area

by gently applying a heated 1/8 in.

diameter steel rod to the areas of wax

that have been damaged, smoothing it

back over areas where bare metal is

exposed.

NOTICE

Only retouching of the wax coating

applied to the wrenching area and

frame arms is permitted, and the

retouching is to be performed only at

the time of the initial nozzle installation.

The steel rod should be heated only

to the point at which it can begin to

melt the wax, and appropriate precau-

tions need to be taken when handling

the heated rod in order to prevent the

installer from being burned.

NOTES:

1. Design data obtained from tests in still air.

2. Design data applies to a residual (flowing) pressure range at the nozzle inlet of 20 to 60 psi (1,4 to 4,1 bar). For

pressures up to 175 psi (12,1 bar) consult Johnson Controls Technical Services.

Refer to the authority having jurisdiction for their minimum required residual pressures.

3. The shapes of the Design Spray Profiles remain essentially unchanged over the maximum Axial Distances shown

in Tables E and F.

4. For axial distances of 2 feet (0,6 meters) and less and for nozzle spray angles of 65° to 140°, the Design Spray

Profile is the same as the nominal spray angle.

5. The maximum Axial Distances shown in Tables E and F are based on exposure protection.

95°

65°

80°

110°

125°

140°

160°

180°

0

16

14

12

10

8

6

4

2

0

2

4

6

8

RADIAL DISTANCE FROM

NOZZLE CENTERLINE, FEET

AXIAL DIST

ANCE FROM NOZZLE, FEET

125°

140°

160°

95°

80°

110°

65°

180°

AXIAL DIST

ANCE FROM NOZZLE, METRES

RADIAL DISTANCE FROM

NOZZLE CENTERLINE, METERS

2,5

2,0

1,5

1,0

0,5

0

4,5

4,0

3,5

3,0

2,5

2,0

1,5

1,0

0

0,5

RADIAL

DISTANCE

GRAVITY

FIXED ANGLE

SPRAY

PROFILE

(ORIENTATION)

PROTECTION

PLANE OF

NOZZLE

AXIAL DISTANCE

FIGURE 2

WATER DISTRIBUTION DESIGN DATA

FIGURE 3

W-TYPE 11

SPRINKLER WRENCH