TFP852

Page 6 of 6

1400 Pennbrook Parkway, Lansdale, PA 19446 | Tel1-215-362-0700

© 2020 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision date and are subject to change without notice.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indicate

the full product name and part number

(P/N).

Model TN-17 Horizontal

Spray Nozzle

Specify: Model TN-17 Horizontal Spray

Nozzle, K=16.8, (specify) Thread Con-

nection, P/N (specify):

ISO 7-R 3/4. . . . . . . . . . . . . . . . . . . 49-017-2-001

3/4 in. NPT . . . . . . . . . . . . . . . . . . . 49-017-2-002

ISO 7-R 3/4 w/ Dust Cap . . . . . . . . 49-017-3-001

3/4 in. NPT w/ Dust Cap . . . . . . . .49-017-3-002

Sprinkler Wrench

(separately ordered)

Specify: W-Type 21 Sprinkler Wrench,

P/N 56-001-0-686

Care and

Maintenance

The TYCO Model TN-17 K=16.8 Hori-

zontal Spray Nozzle must be main-

tained and serviced in accordance with

this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and notify all personnel who may be

affected by this action.

Nozzles which are exhibiting visible

signs of corrosion must be replaced.

Care must be exercised to avoid

damage to the nozzles before, during,

and after installation. Nozzles damaged

by dropping, striking, wrench twist/slip-

page, or the like, must be replaced. See

the Installation section for additional

information.

The Tunnel Operator is responsi-

ble for the inspection, testing, and

maintenance of their fire protection

system and devices in compliance

with this document, in addition to the

standards of any authorities having

jurisdiction. Contact the installing con-

tractor or product manufacturer with

any questions.

Fire protection systems are recom-

mended to be inspected, tested, and

maintained by a qualified Inspec-

tion Service in accordance with local

requirements and/or national codes.

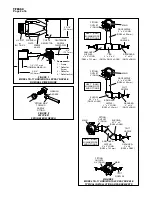

Installation

The TYCO Model TN-17 K=16.8 Hori-

zontal Spray Nozzle, as shown in

Figures 1 and 2, must be installed in

accordance with this section.

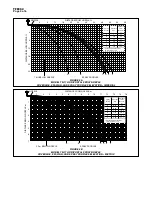

NOTICE

The Model TN-17 Nozzle must be

installed in accordance with the pipe

dimensions shown in Figure 3. Failure

to do so will impair the intended perfor-

mance of the system.

General Instructions

The Model TN-17 Nozzle is to be ori-

ented horizontally with the plane

created by its two frame arms paral-

lel with the ceiling or parallel with the

finished grade, in the case of a non-flat

ceiling.

Step 1.

Ensure all piping components

are properly assembled as shown in

Figure 3 prior to installing the Model

TN-17 Nozzle.

Step 2.

With pipe-thread sealant

applied to the nozzle threads, hand-

tighten the Model TN-17 Nozzle into

the Reducer.

Step 3.

The Model TN-17 Nozzle must

be tightened using only the W-Type 21

Sprinkler Wrench as shown in Figure 2.

Fully engage the nozzle wrench flats as

shown in Figure 1 and wrench tighten.

A leak-tight 3/4 in. NPT or ISO 7-R

3/4 sprinkler joint should be obtained

by applying a minimum-to-maximum

torque of 20 to 30 ft-lb (26,8 to 40,2

N

∙

m). Higher levels of torque can

distort the nozzle inlet with consequent

leakage or impairment of the nozzle.

Ensure the markings on the deflector

face towards the ceiling.