TYCROP Manufacturing Ltd.

ProPass 180 Top Dresser Operator’s Manual

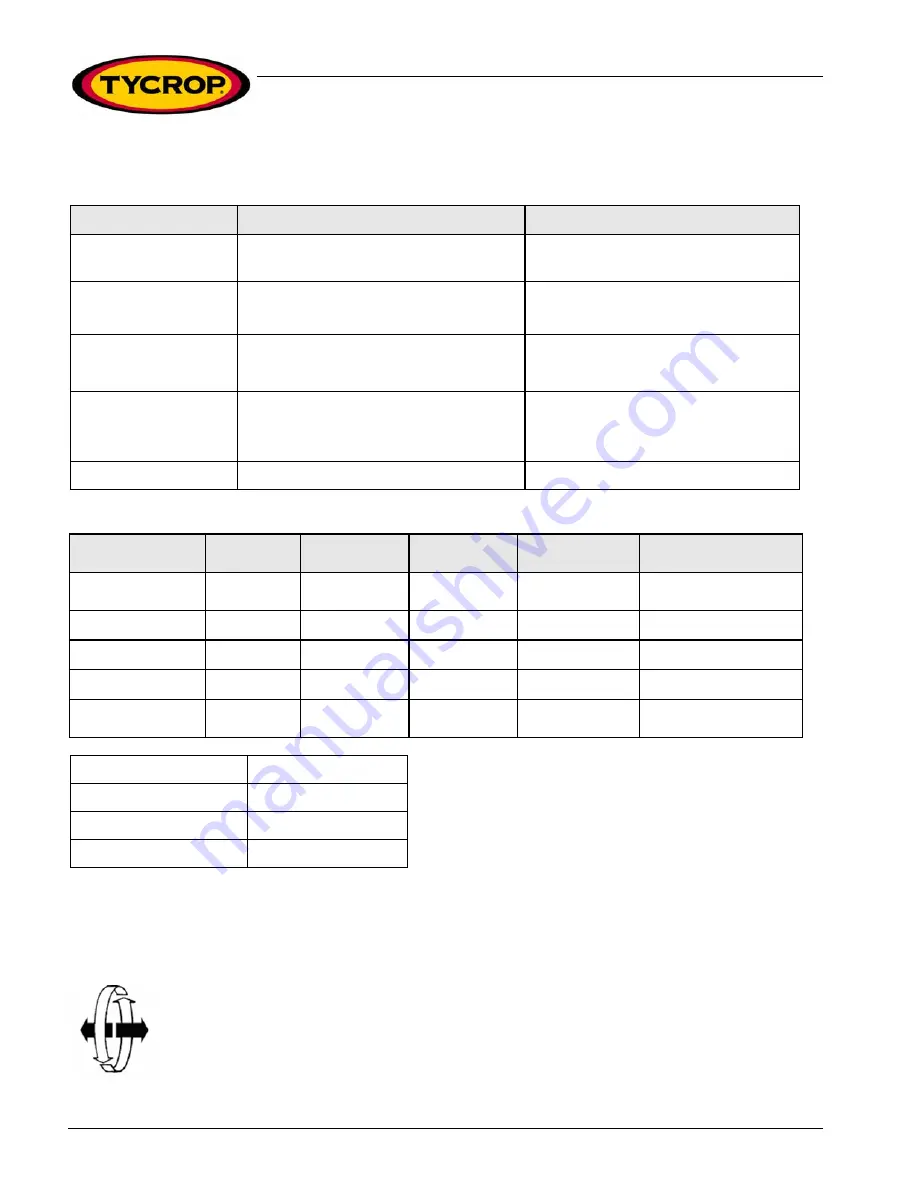

ProPass Factory-Recommended Settings Guide

ProPass

Settings for Best Performance

Additional Performance

Hitch position

Level

Use the multi-position hitch to raise or lower

the ProPass for maximum performance.

Twin Spinner settings

Paddle position: factory setting

Test the spread pattern in a neutral area,

then make very small adjustments.

On/off pendant

Twin Spinner: Leave on during top dressing.

Conveyor belt: Turn on and off for each pass.

At the start of each new load, it takes 1 to 3

seconds for material to reach the Twin

Spinner and begin discharging.

Tow vehicle r/min

Full throttle

An engine at full r/min provides the

maximum hydraulic flow. Always warm up

the engine and the hydraulic system before

use.

Ground speed

4 to 5 mi/h

Travel at about the speed of a fast walk

ProPass Twin Spinner Suggested Spreading Application Guide

Application

Twin Spinner

Floor Control

Rear Gate

Base and Disk

Settings

Comments

Ultra Light

10

7

10 mm (3/8”)

Wide

No dragging or no

watering in

Light

10

10

10 mm (3/8”)

Wide

Water in

Medium Light

10

10

25 mm (1”)

Wide

Water in

Medium

3-3.5

10

50 mm (1.5”)

Medium

Drag or water in

Heavy

2.5-3

10

79 mm (3.13”)

Narrow

After quarantining or

aerification

Maximum pressure input

190 bar (2,800 psi)

Minimum pressure input

138 bar (2,000 psi)

Maximum flow input

37.9 L/m (10 U.S. gal/m)

Minimum flow input

22.7 L/m (6 U.S. gal/m)

Note

: Different materials vary in the size of their particles, causing variations in the spread pattern. Before top dressing the

required area, test new materials by spreading them in an open area away from bystanders.

Figure 19: Handle Operations

Page 26

Operating Instructions