Installation & Service Manual

N7DNL, NHD

June, 2007

Page 17

TYPE OF CLEANING CLEANING AGENT* APPLICATION METHOD**

EFFECT ON FINISH

Liquid NuSteel

Rub with dry cloth. Use a

Use in direction of polish lines

small amount of cleaner.

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Paste NuSteel or DuBois

Rub with dry cloth. Use a

Use in direction of polish lines

Temp

small amount of cleaner.

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Cooper’s Stainless Steel

Apply with damp sponge or.

Use in direction of polish lines

Cleaner, Revere Stainless

cloth.

on No. 4 (polished) finish.

Steel Cleaner

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Grade F Italian pumice, Steel

Rub with a damp cloth.

Use in direction of polish lines

Bright, Lumin Cleaner, Zud or

on No. 4 (polished) finish.

Restoro

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Penny-Brite or Copper-Brite

Rub with a dry cloth. Use a

Use in direction of polish lines

small amount of cleaner.

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Heat tint or heavy

Penny-Brite or Copper-Brite

Rub with a dry cloth.

Use in direction of polish lines

discoloration

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Paste NuSteel or DuBois

Rub with dry cloth. Use a

Use in direction of polish lines

Temp

small amount of cleaner.

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Revere Stainless Steel

Apply with a damp sponge

Use in direction of polish lines

Cleaner

or cloth.

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Allen Polish, Steel Bright,

Rub with a damp cloth.

Use in direction of polish lines

Wyandotte or Zud

on No. 4 (polished) finish.

May scratch No. 2 (mill) and

No. 7 and 8 (polished) finishes.

Burnt-on foods and

Easy-Off, De-Grease-It, 4-6%

Apply generous coating.

Excellent removal, satisfactory

grease, fatty acids,

hot solution of such agents

Allow to stand for 10-15 min.

for use on all finishes.

milkstone (where swab-

as trisodium tripolyphospate, Repeated application may

bing or rubbing is not

or 5-15% caustic soda

be necessary.

practical)

solution

Tenacious deposits,

Oakite No. 33, Dilac, Texo 12, Swab and soak with clean

Satisfactory for use on all

rusty discolorations,

Texo N.Y., Flash-Klenz,

cloth. Let stand 15 minutes

finishes.

industrial atmospheric

Caddy Cleaner, Turco Scale

or more according to direc-

stains

4368 or Permag 57.

tions on package. Rinse

and dry.

Hard water spots

Vinegar

Swab or wipe with a cloth.

Satisfactory for use on all

and scale

Rinse with water and dry.

finishes.

5% oxalic acid, 5% sulamic

Swab or soak with a cloth.

Satisfactory for use on all

acid, 5-10% phospheric acid,

Let stand 10-15 minutes.

finshes. Effective on tenacious

or Dilac, Oakite No. 33,

Always follow with neutralizer deposites or where scale has

Texo 12 or Texo N.Y.

rinse, and dry.

built up.

Summary of Contents for N7DNL

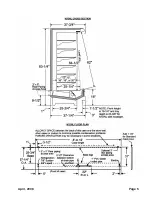

Page 5: ...April 2008 Page 5 ...

Page 6: ...Page 6 April 2008 NHD L M Extended Height Multi Shelf Medium Temp Merchandisers ...

Page 7: ...April 2008 Page 7 ...

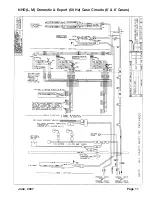

Page 10: ...June 2007 Page 10 N7DNL Domestic Export 50 Hz Case Circuits 12 Cases ...

Page 11: ...June 2007 Page 11 NHD L M Domestic Export 50 Hz Case Circuits 6 8 Cases ...

Page 12: ...Page 12 June 2007 ...

Page 13: ...June 2007 Page 13 NHD L M Domestic Export 50 Hz Case Circuits 12 Cases ...

Page 14: ...Page 14 June 2007 ...

Page 25: ...Installation Service Manual N7DNL NHD June 2007 Page 25 NHDM ILLUSTRATED ...