Defrost Information

See “General-UL/NSF I&S Manual” for oper-

ational descriptions for each type of defrost

control.

Defrost Control Chart

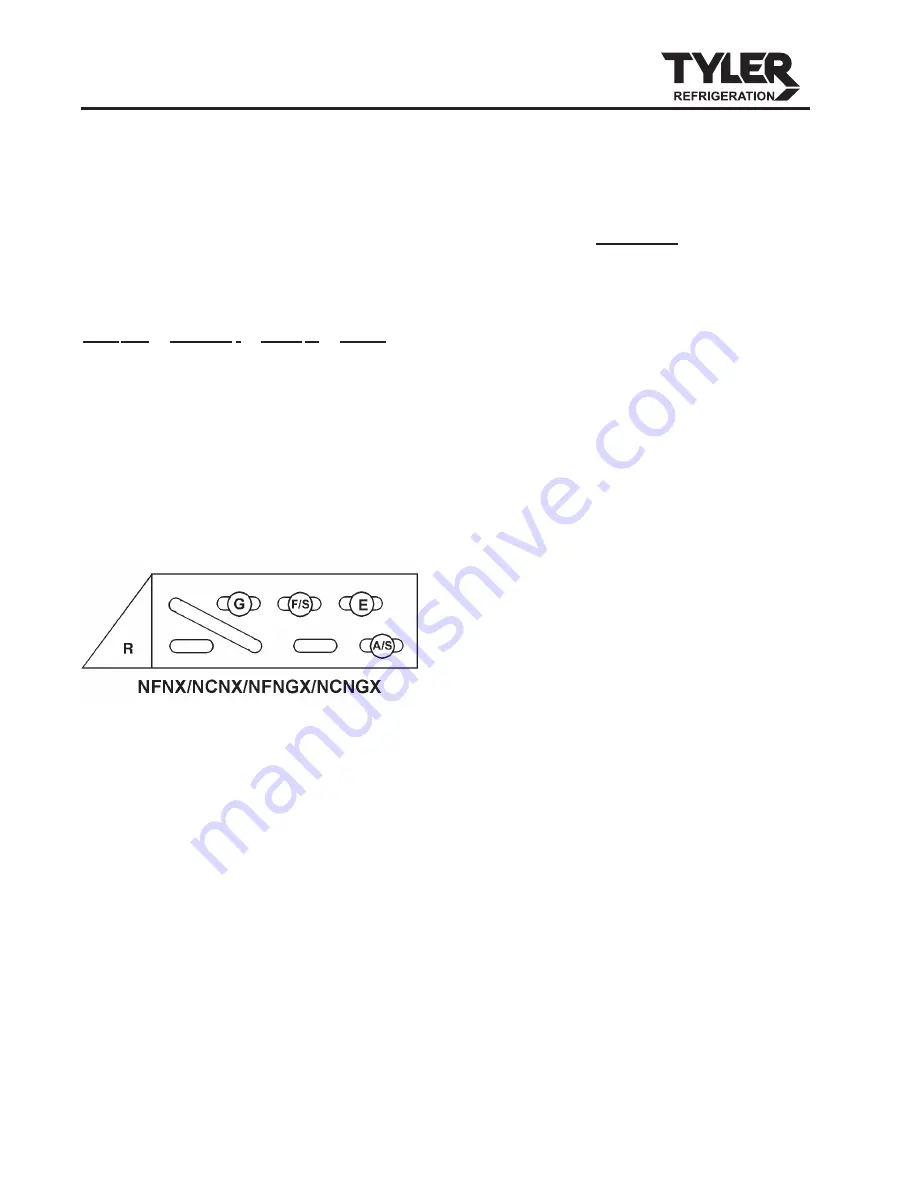

NFNX/NCNX/NFNGX/NCNGX

Defrost

Defrost

Defrosts

Duration

Term.

Type

Per Day

(Min)

Temp.

Electric/FF

1

60

50°F

Electric/IC

1

36

50°F

Electric/MED

1

36

50°F

Gas/FF

2-3

20-25

55°F

Gas/IC

1

25-30

55°F

Gas/MED

2-3

16-20

55°F

E = Electric Defrost Termination

F/S = Electric Defrost Failsafe (Opt.)

G = Gas Defrost Fan Delay (Dual Temp)

A/S = Glass Anti-Sweat (Dual Temp)

Most klixons are located on the end of the

evaporator coil. The diagram shows the

location for each defrost type that uses a

klixon.

NOTE

The defrost termination klixon for gas

defrost is located at the bypass check

valve.

CAUTION

If electronic sensors are used in place of

the klixons, the sensors must be located in

the same location as the klixons for that

defrost type. Any other locations will

effect the refrigeration efficiency of the

case.

WIRING DIAGRAMS

ELECTRICIAN NOTE - OVERCURRENT

PROTECTION

120V circuits should be protected by 15 or 20 Amp

devices per the requirements noted on the cabinet

nameplate or the National Electrical Code, Canadian

Electrical Code - Part 1, Section 28. 208V defrost

circuits employ No. 12 AWG field wire leads for field

connections. On remote cases intended for end to

end line-ups, bonding for ground may rely upon the

pull-up bolts.

The following wiring diagrams on pages 9

thru 12 will cover the NFN(G)X/NCN(G)X

case circuits and dual temp circuits with

electric and hot gas defrost options.

November, 2007

Page 8

NFNX, NCNX, NFGNX,

NCNGX

Summary of Contents for Advantage NFNX

Page 5: ...Installation Service Manual NFNX NCNX NFNGX NCNGX March 2008 Page 5 ...

Page 9: ...NF G NX NC G NX Domestic Export 50 Hz Case Circuits Page 9 November 2007 ...

Page 10: ...November 2007 Page 10 ...

Page 11: ...Page 11 November 2007 Dual Temperature Control Circuits ...

Page 12: ...November 2007 Page 12 ...

Page 19: ...NFNX NCNX NFNGX NCNGX Installation Service Manual Page 19 November 2007 ...

Page 21: ...NFNX NCNX NFNGX NCNGX Installation Service Manual Page 21 November 2007 ...