50

CHAPTER 6 TECHNICAL MAINTENANCE OF TRACTOR

6.1 Technical Maintenance per Shift

The following maintenance work should be made before and after each shift.

(1) Fill fuel, lubricating oil and grease according to the instructions of oil chart and table.

(2) Check the water lever of the radiator and replenish it if necessary.

(3) Inspect whether there is dirt or water in the fuel sediment cup. Clean it and expel the air from the

fuel line.

(4) Inspect and remove any leakage of oil, water and air from the fittings.

(5) Check and tighten fasteners of all fittings.

(6) Check the tire and its inflation pressure.

(7) Check and bring along all the necessary tools.

(8) Clean the dust on the surface of the batteries and the rust of the battery terminals. Check the

electrolyte lever in the batteries (18 ~ 23 mm above the separator), add distilled water if it is

insufficient. Check should be done every 60 hours when working in winter or in wet area.

6.2 1st Technical Maintenance

The following maintenance work should be made after every 100 hours of working.

(1) Complete all the maintenance items in technical maintenance per shift.

(2) Change the oil in the oil sump.

(3) Wash the fuel tank and its inlet screen.

(4) Wash the oil filter and change the element if necessary.

(5) Wash the cleaner and change the oil or clean the dust of air cleaner element.

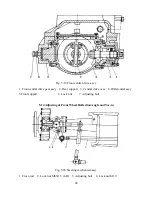

(6) Check the tension of the fan belt by pressing with thumb nearly midway on its straight portion,

if the belt deflects about 15 mm the tension is correct.

(7) Turn off the plugs on each side of transmission brakes and the plug under the flywheel housing.

Check and drain any oil that may leak out.

Summary of Contents for ET350 ECONO

Page 69: ...62 8 3 Electrical system wiring diagram...

Page 73: ...66 ET 350 ECONO 4WD TRACTOR ENGINE PARTS CATALOGUE...

Page 74: ...67 1 INTAKE AND EXHAUST PIPE ASSEMBLY...

Page 76: ...69 2 CYLINDER HEAD ASSEMBLY...

Page 80: ...73 3 CYLINDER BLOCK ASSEMBLY...

Page 84: ...77 4 CAMSHAFT ASSEMBLY...

Page 86: ...79 5 CRANKSHAFT FLYWHEELASSEMBLY...

Page 88: ...81 6 PISTON CONNECTING ROD ASSEMBLY...

Page 90: ...83 7 FUEL SYSTEM ASSEMBLY...

Page 92: ...85 8 COOLING SYSTEM...

Page 95: ...88 9 LUBRICATION SYSTEM ASSY...

Page 97: ...90...

Page 98: ...91 Electric EGR Illustration Diagram...

Page 100: ...93 ET 350 ECONO 4WD TRACTOR Chassis PARTS CATALOGUE...

Page 102: ...95 1 DRY AIR FILTER...

Page 104: ...97 2 ENGINE CONTROL MECHANISM ASSY...

Page 107: ...100 3 CLUTCH...

Page 110: ...103 4 INTERMEDIATE HOSE ASSY...

Page 113: ...106 5 TRANSMISSION HOUSING...

Page 116: ...6 PRIMARY SHAFT 109...

Page 118: ...7 MAIN SHAFT 111...

Page 120: ...8 TRANSMISSION COVER ASSY 113...

Page 122: ...9 DIFFERENTIAL 115...

Page 124: ...10 PTO SHAFT ASSY 117...

Page 126: ...11 BRAKE ASSY 119...

Page 129: ...122 12 REAR DRIVING WHEEL ASSY...

Page 131: ...124 13 FINAL DRIVE ASSY...

Page 134: ...14 FUEL TANK BRACKET 127...

Page 136: ...15 SUSPENSION LINKAGE ASSY 129...

Page 139: ...16 FRONT DRIVING AXLE ASSY A 132...

Page 142: ...17 FRONT DRIVING AXLE ASSY B 135...

Page 145: ...138 18 FRONT DRIVING AXLE ASSY C...

Page 147: ...140 19 FRONT DRIVING AXLE ASSY D...

Page 150: ...143 20 FRONT DRIVING WHEELASSY...

Page 152: ...145 21 STEERING MECHANISM...

Page 154: ...147 22 TRANSFER CASE ASSY...

Page 157: ...150 23 HYDRAULIC POWER LIFT...

Page 160: ...153 24 POWER LIFT CONTROL MECHANISM...

Page 163: ...156 25 CYLINDER DISTRIBUTOR ASSY...

Page 166: ...159 26 FENDER FLOOR BOARD TOOL BOX...

Page 168: ...161 27 BONNET 1...

Page 171: ...164 28 BONNET 2...

Page 173: ...166 29 SIDE COVER...

Page 175: ...ET350 ECONO OPERATOR S MANUAL FOR TRACTORS CODE NO Printed on June 2006 2 nd EDITION...