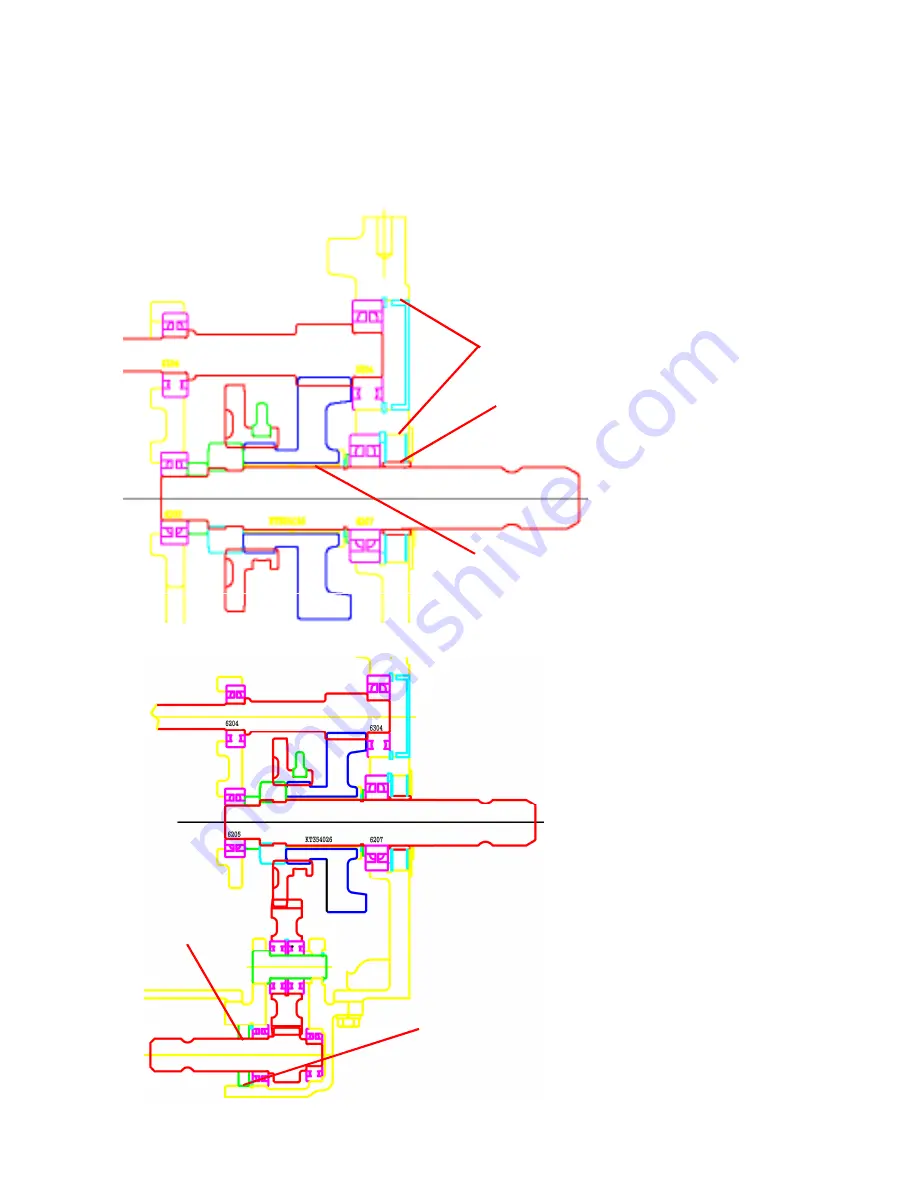

(2) PTO shaft and related parts.

a.Pushing the PTO counter gear end into the bearing until the stop on the gear is securely seated

against the bearing.The seal should be coated with an adhesive (THREE BOND TB1215) on the

circumference before installing.

b.Install the oil seal on the PTO shaft,paying attention to its installed direction.

c.After installation,the slide coupling should smoothly slide and mesh with the designated gears.

Fig.5-37

Apply grease

Apply adhesive

(TB1215)

Apply oil

(3) MID PTO shaft and related parts.

Fig.5-37

Fig.5-38

Apply grease

Apply grease

Apply adhesive

(TB1215)

Fig.5-35

Fig.5-36

5-23

Summary of Contents for T233 HST

Page 14: ...1 11...

Page 15: ...1 12...

Page 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Page 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Page 60: ...3 HST main pump case 4 5...

Page 64: ...6 Hydrostatic system schematic 4 8...

Page 100: ...3 Rear transmission case 5 15 Fig 5 23...

Page 121: ...Power Train Diagram Fig 5 60 5 36...

Page 210: ...SECTION 6 WIRING DIAGRAM 10 12...