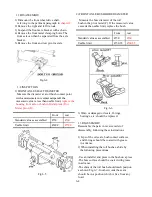

7) Sub change counter shaft

8) Differential gears.

Note:

1.Apply grease when installing Needle bearing.

2.After installation, be sure to slide smoothly.

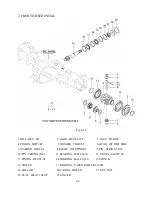

1.C-RING , SHAFT

2.GEAR , SPUR 21T

19.BEARING , BALL/HL1

(6206)

20.GEAR , SPUR 19-28T

21.BEARING , NEEDLE.

ROLLER (KT252913)

22.GEAR , SPUR 28T

23.WASHER , 20X34X3

24.BEARING,

BALL/HL1(6304)

13.C-RING , HOLE 14.SHIM , 0.5 (3)

15.SHIM , 0.2 (4) 16.SHIM , 0.1 (3)

17.DIFF ASSY , RR

18.PINION , DRIVE 9T

19.GEAR , BEVEL 55T 20.CASE , DIFF

21.PINION , DIFF 12T

29 28 25 26 19

27

25

22 21 24 23

20 31 30

13

14 15 16

32 33

34 35

Fig.5-53

Note:

1.When assembling without replacing the pinion gear and ring gear with new ones, provide the

same shimming thickness as that provided before disassembly.

2.Backlash between diff-pinion and diff-side gear should be within as range of 0.1 to 0.2mm

(0.004-0.008 in) and these parts should turn smoothly.

3.When reassembling the used pinion and ring gear, reinstall the same thickness of shims as was

installed before disassembly in each shimming position.

4.Backlash adjustment between the drive pinion and the ring pair(Fig5-34).As the drive pinion

and the ring gear make a pair,be sure not to mate them with other parts from differential

tractors.

5.Adjust the shimming to backlash of 0.1-0.2 mm (0.004-0.008 in). The standard shimming is

2.6mm (0.102 in

) on right side and

1.1mm (0.043in)

on left side.

5-32

21.PINION , DIFF 12T

22.COLLAR , PINION THRUST

23.SHAFT , DIFF PINION 24.PIN , SPRING

25.WASHER, THRUST 34X46X1

26.GEAR , BEVEL RH 20T

27.GEAR , BEVEL LH 20T

28.CLUTCH COMP , DIFF LOCK

29.BEARING , BALL 30.BOLT , HEX/S

31.BEARING , BALL

32.SHIM , 0.2 (8) 33.SHIM , 0.1 (6)

34.METAL , DIFF CASE

35.BOLT , HEX/S

Fig.5-54

20 31 30

18

Summary of Contents for T233 HST

Page 14: ...1 11...

Page 15: ...1 12...

Page 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Page 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Page 60: ...3 HST main pump case 4 5...

Page 64: ...6 Hydrostatic system schematic 4 8...

Page 100: ...3 Rear transmission case 5 15 Fig 5 23...

Page 121: ...Power Train Diagram Fig 5 60 5 36...

Page 210: ...SECTION 6 WIRING DIAGRAM 10 12...