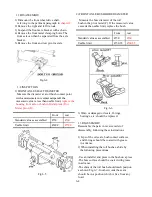

Fig.6-16

3) DIF CASE AND BEVEL PINION

1.shim

2.shim

3.shim

4.Parallel pin

1) Each friction surface should be coated

with grease in advance.

2) The bevel pinion and the ring gear make

a distinct pair after a mesh adjustment

performed at the factory. Consequently,

when reassembling the pair,be sure to

pair parts with a same reference number.

3) When installing the TRB’s from the

bevel pinion,Be sure the calking of the

lock nut and the bearings.

4) Install the snap ring and the bevel pinion

can then be installed together with the

TRB’s (Fig.6-17)

Fig.6-17

Note: Discard the removed straight pin and oil

seal and install a new pin and Oil seal

when reassembled,because this pin and oil

seal is apt to be damaged when removed.

5) Install the bearings from the Axle housing

And the ring gear,and then the ring gear can

be assembled from the Axle housing.

6) Install the straight pin(4) which retains the

axle housing.

7) When any of the bevel pinion,ring gear, TRB,

collar, etc. has been replaced,inspect the bevel

pinion assembly for thrust play in the front

axle housing through drain plug hole.

Specified thrust play

mm(in)

0.1-0.2

(0.004-0.008 in)

6-9

Summary of Contents for T233 HST

Page 14: ...1 11...

Page 15: ...1 12...

Page 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Page 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Page 60: ...3 HST main pump case 4 5...

Page 64: ...6 Hydrostatic system schematic 4 8...

Page 100: ...3 Rear transmission case 5 15 Fig 5 23...

Page 121: ...Power Train Diagram Fig 5 60 5 36...

Page 210: ...SECTION 6 WIRING DIAGRAM 10 12...