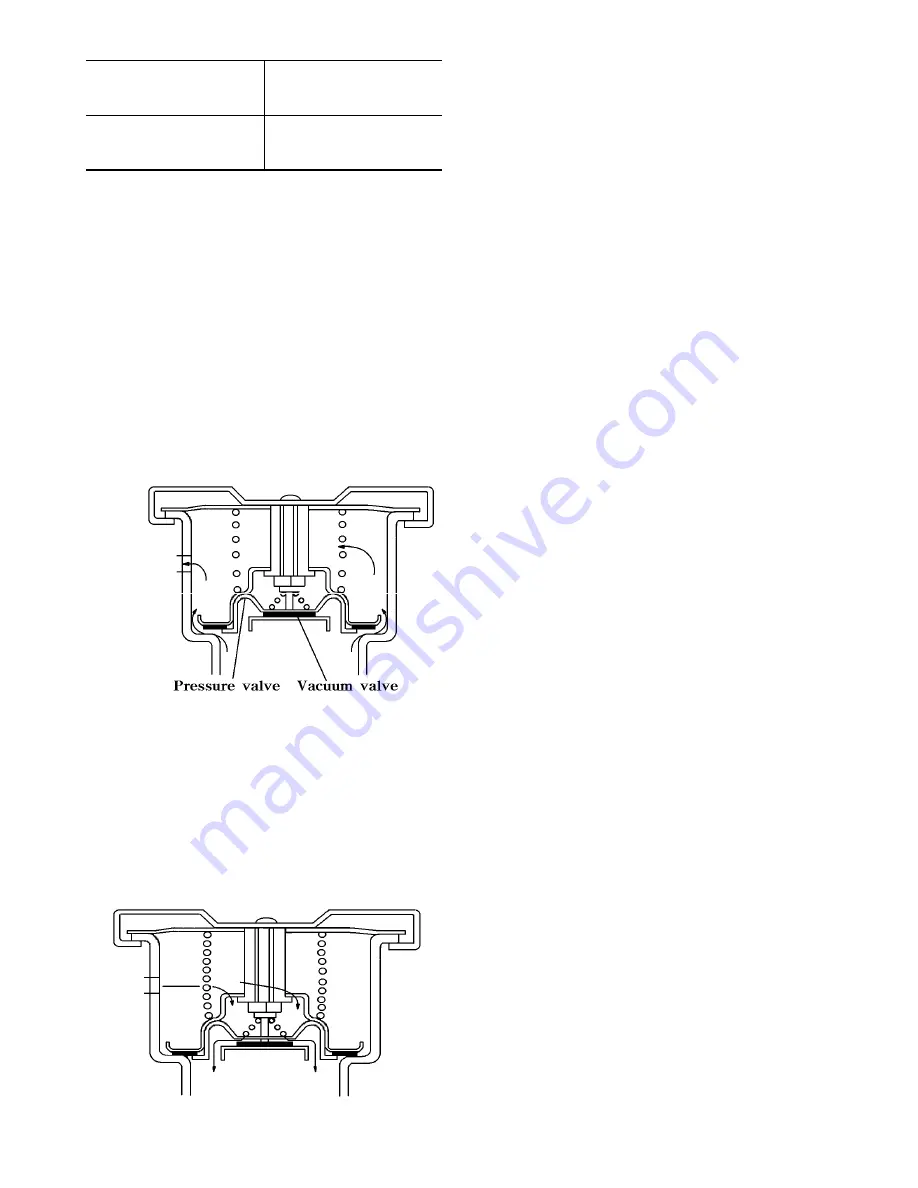

Pressure valve

Opening pressure

0.9 Kgf/

㎠

(12.79 psi)

Vacuum valve

Opening pressure

0.04-0.05 Kgf/

㎠

(0.57-0.71psi)

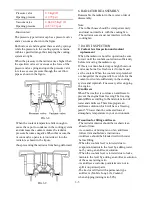

-Function test:

The pressure type radiator cap has a pressure valve

and a vacuum as shown in the figure.

Both valves are held against there seats by springs

while the pressure in the cooling system remains

within a specified range,thus keeping the cooling

system air-tight.

When the pressure in the radiator rises higher than

the specified valves,it overcomes the force of the

pressure valve spring and open the pressure valve

to release excess pressure through the overflow

pipe as shown in the figure.

6. RADIATOR REASSEMBLY

Reassemble the radiator in the reverse order of

disassembly.

Note:

- The rubber hoses should be clamped securely

and must not interfere with the cooling fan.

- The radiator cores must not interfere with the

cooling fan.

7. DAILY INSPECTION

1) Coolant level inspection and coolant

replacement

When the radiator is hot after operation,be sure

to wait until the coolant cools down sufficiently

before removing the radiator cap.

If this is not done,heated vapor might burst out

and cause burns.Use fresh water from a faucet

as the coolant. When the coolant is replenished

or changed,let the engine idle for a while for the

coolant to circulate sufficiently in the cooling

system and replenish if necessary after stopping

the engine.

2)Antifreeze

When The weather is cold,use an antifreeze to

prevent the engine from freezing.The freezing

point differs according to the mixture ration of

FIG.3-8

When the coolant temperature falls enough to

cause the vapor to condense in the cooling system

and decrease the coolant volume,the radiator

pressure becomes negative.When this occurs,the

vacuum valve opens to let outside air into the

radiator as shown in the figure,

thus preventing the radiator from being deformed.

FIG.3-9

point differs according to the mixture ration of

water and antifreeze.Therefore,prepare an

antifreeze solution which will have a freezing

point 5

℃

lower than the estimated lowest

atmospheric temperature in your environment.

Precaution for filling antifreeze.

- The radiator interior should be washed clean

ahead of time.

- As concerns of mixing ratio of an antifreeze,

follow its manufacture's instructions.

- Antifreeze should be blended well with water

before filling.

- When the coolant level is lowered due to

evaporation,maintain the level by adding water,

not by using an antifreeze solution.

- When the coolant level is lowered due to leaks,

maintain the level by adding an antifreeze solution

of the same mixing ratio.

- As antifreeze corrodes point,take care not to

spill it on painted parts.

-The tractor is filled with a permanent type

antifreeze (Mobile Long Life Coolant)

when shipping(mixing ratio:50%)

3- 5

Summary of Contents for T233 HST

Page 14: ...1 11...

Page 15: ...1 12...

Page 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Page 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Page 60: ...3 HST main pump case 4 5...

Page 64: ...6 Hydrostatic system schematic 4 8...

Page 100: ...3 Rear transmission case 5 15 Fig 5 23...

Page 121: ...Power Train Diagram Fig 5 60 5 36...

Page 210: ...SECTION 6 WIRING DIAGRAM 10 12...