CHECKS AND SERVICE

PRE-START CHECKS

To avoid problems it is recommended that a range of checks be carried out daily before starting the tractor.

For full details of the items and frequency please refer to the tables on page

60,61 and 62.

▶

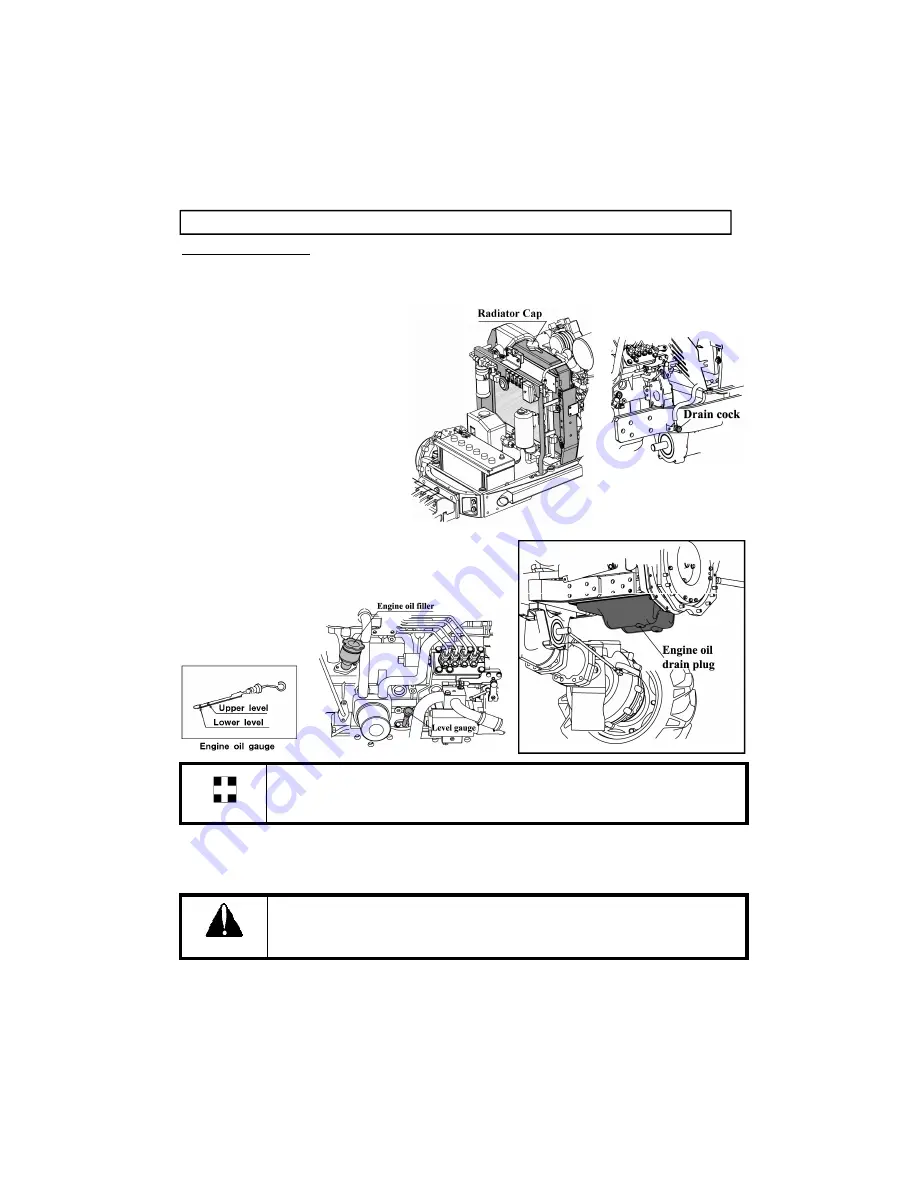

Engine coolant

Remove the radiator cap and ensure that the

coolant is up to the filler neck and that it is

clean with the correct anti-freeze or anti

corrosion inhibitor in it.

If the coolant is a rusty color, drain the

system completely and refill with the

correct mixture of water and anti-freeze or

corrosion inhibitor.

▶

Engine oil

Pull out the stick, wipe it and dip in the oil sump.

Ensure that oil level is between the upper and lower mark

near the upper mark. If too low add oil, but never excess

100hrs

of service intervals

.

58

100hrs

of service intervals

.

Do not overfill the crankcase with oil.

▶

Transmission oil

Check the level with the dipstick on top of the transmission in rear of the seat.

If the level is low add oil through the filler hole.

Always ensure that you use the correct oil for topping up or oil changes

Caution

important

Summary of Contents for T603

Page 2: ......

Page 34: ......

Page 82: ......

Page 105: ...T603 CABIN WIRING DIAGRAM A3 103 ...

Page 106: ......

Page 107: ...T603 ROPS WIRING DIAGRAM A3 105 ...

Page 108: ......

Page 109: ...T603 WIRING DIAGRAM FOR POWER SHUTTLE If equipped 105 ...

Page 110: ......

Page 111: ...WIRING DIAGRAM 107 ...

Page 112: ...CABIN WIRING DIAGRAM 108 ...

Page 113: ...CABIN WIRING DIAGRAM 109 ...

Page 115: ... T603 POWER TRAIN 111 ...

Page 116: ... T603 POWER TRAIN FOR POWER SHUTTLE If equipped 111 ...

Page 118: ...DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT SERVICE RECORD 113 ...

Page 120: ...PART REPLACEMENT RECORD DATE PART DESCRIPTION QTY COST DATE PART DESCRIPTION QTY COST 115 ...

Page 121: ...T603 Operator s Manual for Tractors Code No 1995 940 002 1 Printed on August 2008 3rd Edition ...