■

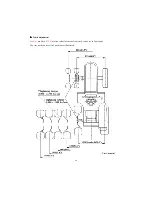

FUEL FILTER

The fuel filter/water separator (if equipped) is

not usually supplied by Perkins. The following

test describes a typical fuel filter/water separator.

Refer to the OEM information for further

information in the fuel filter/water separator.

Turn the fuel supply valve (if equipped) to the

OFF position before performing this

maintenance. Place a tray under the fuel filter in

order to catch any fuel that might spill. Clean up

any spilled fuel immediately.

1. Close the fuel supply valve (if equipped).

2. Clean the outside of the fuel filter assembly.

Note: If the fuel filter element is mot equipped with a drain, remove cap. Remove the nylon insert in order

to reduce the lever of fuel in the fuel filter element. A reduction in the level of fuel in the fuel filter

69

to reduce the lever of fuel in the fuel filter element. A reduction in the level of fuel in the fuel filter

element will help prevent fuel from being spilled when the element is removed.

Notice: Do not use a tool in order to remove the fuel filter. Attempting to remove the fuel filter with a

filter wrench or a filter strap could damage the locking ring.

3. Hold fuel filter and rotate quick release collar counterclockwise. Removed and discarded.

Note: If the element is equipped with a sediment bowl, remove the sediment bowl from the element.

Thoroughly clean the sediment bowl. Inspect the O-ring seals. Install new O-ring seals, if necessary.

Install the sediment bowl to the new element. Hand tighten the sediment bowl. Hand tighten the

sediment bowl. Hand tightening is the only method that should be used.

Notice: Do not fill fuel filters with fuel before installing them. Contaminated fuel will cause accelerated

wear to fuel system parts.

4. Ensure that the fuel filter base is clean. Push a new fuel filter fully into the fuel filler base.

5. Hold the fuel filter in place. Fit locking ring into position. Rotate the locking ring clockwise in order to

fasten the fuel filter to the fuel filter base.

6. Open the fuel supply valve (If equipped)

Summary of Contents for T603

Page 2: ......

Page 34: ......

Page 82: ......

Page 105: ...T603 CABIN WIRING DIAGRAM A3 103 ...

Page 106: ......

Page 107: ...T603 ROPS WIRING DIAGRAM A3 105 ...

Page 108: ......

Page 109: ...T603 WIRING DIAGRAM FOR POWER SHUTTLE If equipped 105 ...

Page 110: ......

Page 111: ...WIRING DIAGRAM 107 ...

Page 112: ...CABIN WIRING DIAGRAM 108 ...

Page 113: ...CABIN WIRING DIAGRAM 109 ...

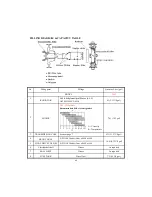

Page 115: ... T603 POWER TRAIN 111 ...

Page 116: ... T603 POWER TRAIN FOR POWER SHUTTLE If equipped 111 ...

Page 118: ...DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT SERVICE RECORD 113 ...

Page 120: ...PART REPLACEMENT RECORD DATE PART DESCRIPTION QTY COST DATE PART DESCRIPTION QTY COST 115 ...

Page 121: ...T603 Operator s Manual for Tractors Code No 1995 940 002 1 Printed on August 2008 3rd Edition ...