SERVICING THE AIR CLEANER

To remove the dust from the evacuator valve squeeze it between

thumb and fingers to let excess dust out and wipe around the

valve to keep it clean from outside.

To clean the main element, remove the right fan cover.

Remove the element by unloading the wing nut.

Remove dust by blowing it out of the element with

Compressed air.Check the element to ensure it is not

damaged.Reassemble the element.

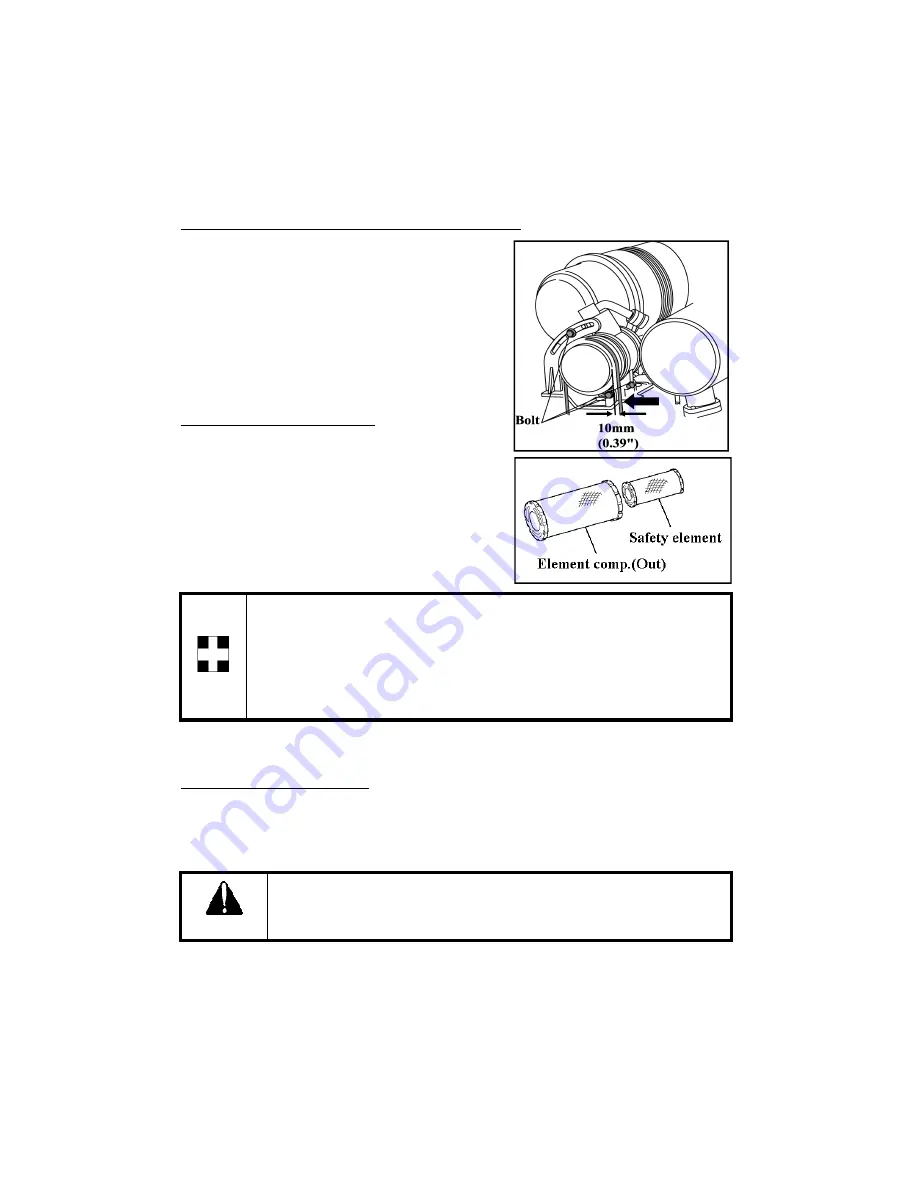

AIR CONDITIONER COMPRESSOR BELT ADJUSTMENT

Check the compressor belt tension regularly and adjust

If required.

The correct tension is if the center of the belt is

Pushed With a finger it moves in approx. 10 mm (0.39 in)

as shown in the picture.

To adjust the belt, loosen the top bolt on the alternator,

move the alternator to the desired position and tighten the

bolt.

Also ensure that the bottom alternator bolts are tighten

Never beat the element on a stone or concrete floor/wall to clean it Check all

connections and hoses especially on the clean side of the air cleaner to ensure no dusty

air can enter the engine.

Check the element for flaws by putting a light inside the element.

When reassembling make sure all surfaces seal correctly to keep dust out.

When working in dusty conditions increase the service frequency.

▶

Replace the element after cleaning it 5 times or it is damaged.

CHECKING HOSES AND LINES.

The fuel lines, radiator hoses, hydraulic and rubber hoses are consumables, which deteriorate by age

and use.

Check them regularly and replace if faulty.

Damaged fuel lines leak and cause fires.

Damaged radiator hoses can cause hot water burns and in severe cases seize the engine.

Caution

77

important

Summary of Contents for T603

Page 2: ......

Page 34: ......

Page 82: ......

Page 105: ...T603 CABIN WIRING DIAGRAM A3 103 ...

Page 106: ......

Page 107: ...T603 ROPS WIRING DIAGRAM A3 105 ...

Page 108: ......

Page 109: ...T603 WIRING DIAGRAM FOR POWER SHUTTLE If equipped 105 ...

Page 110: ......

Page 111: ...WIRING DIAGRAM 107 ...

Page 112: ...CABIN WIRING DIAGRAM 108 ...

Page 113: ...CABIN WIRING DIAGRAM 109 ...

Page 115: ... T603 POWER TRAIN 111 ...

Page 116: ... T603 POWER TRAIN FOR POWER SHUTTLE If equipped 111 ...

Page 118: ...DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT SERVICE RECORD 113 ...

Page 120: ...PART REPLACEMENT RECORD DATE PART DESCRIPTION QTY COST DATE PART DESCRIPTION QTY COST 115 ...

Page 121: ...T603 Operator s Manual for Tractors Code No 1995 940 002 1 Printed on August 2008 3rd Edition ...