FUEL SAVING TIPS

To save fuel & oil in your tractor, following things should always be kept in mind.

A) Air cleaning system

1) Clean the air cleaner regularly so that dust does not settle down.

2) For every 50 hours & everyday in sandy/dusty conditions.

(a) Clean the air cleaner filter element with compressed air.

(b) If the rubber ring is cut or expanded then change it with an appropriate one.

Fix the rubber at the proper location & check for leakages if any.

(c) If air is leaking through the hose connection, check & rectify other leakages, too.

Note: If air cleaning system is not properly maintained, it will lead to early wear of piston rings

& sleeves. This will lead to problems like loss of engine power,, excessive oil consumption

fuel consumption.

B) Engine

1) put the engine oil on load after the engine is heated & the water temperature gauge indicates

the needle to be in the green zone.

2) If excessive black smoke is visible, then the paper element of air cleaner, Fuel injection

Pump or nozzles should be checked.

3) Do not run the engine without load for more than 2 minutes. It is better to stop the engine

97

3) Do not run the engine without load for more than 2 minutes. It is better to stop the engine

rather than run it idle. This will help in saving of fuel.

C) Clutch & Brakes.

1) Do not reduce the power of the power of the engine by depressing the clutch halfway. Instead

use low gear.

2) If the Tractor has to be stopped for a long period, it is advisable to bring the transmission in

neutral position & release the clutch pedal.

3) Do not over ride the clutch & brake pedals.

4) While coming down from a slope, reduce the engine throttle & use low gear. Do not depend

only on the brakes for stoppage.

D) Fuel system

1) Always use filtered diesel for the fuel system

2) At the end of the day’s working, it is preferable to fill the diesel tank so that it may prevent

condensation.

3) Change the filter, if the system gets choked. Do not change both the filters at the same time.

If the above directives are not adhered to, the fuel injection pump & injection nozzle will lose

its life early. Also, it will lead to excessive black smoke & excessive diesel consumption.

Summary of Contents for T603

Page 2: ......

Page 34: ......

Page 82: ......

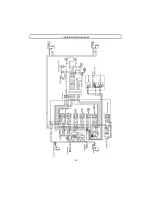

Page 105: ...T603 CABIN WIRING DIAGRAM A3 103 ...

Page 106: ......

Page 107: ...T603 ROPS WIRING DIAGRAM A3 105 ...

Page 108: ......

Page 109: ...T603 WIRING DIAGRAM FOR POWER SHUTTLE If equipped 105 ...

Page 110: ......

Page 111: ...WIRING DIAGRAM 107 ...

Page 112: ...CABIN WIRING DIAGRAM 108 ...

Page 113: ...CABIN WIRING DIAGRAM 109 ...

Page 115: ... T603 POWER TRAIN 111 ...

Page 116: ... T603 POWER TRAIN FOR POWER SHUTTLE If equipped 111 ...

Page 118: ...DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT SERVICE RECORD 113 ...

Page 120: ...PART REPLACEMENT RECORD DATE PART DESCRIPTION QTY COST DATE PART DESCRIPTION QTY COST 115 ...

Page 121: ...T603 Operator s Manual for Tractors Code No 1995 940 002 1 Printed on August 2008 3rd Edition ...