15

A

A

a

b

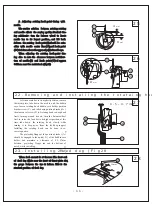

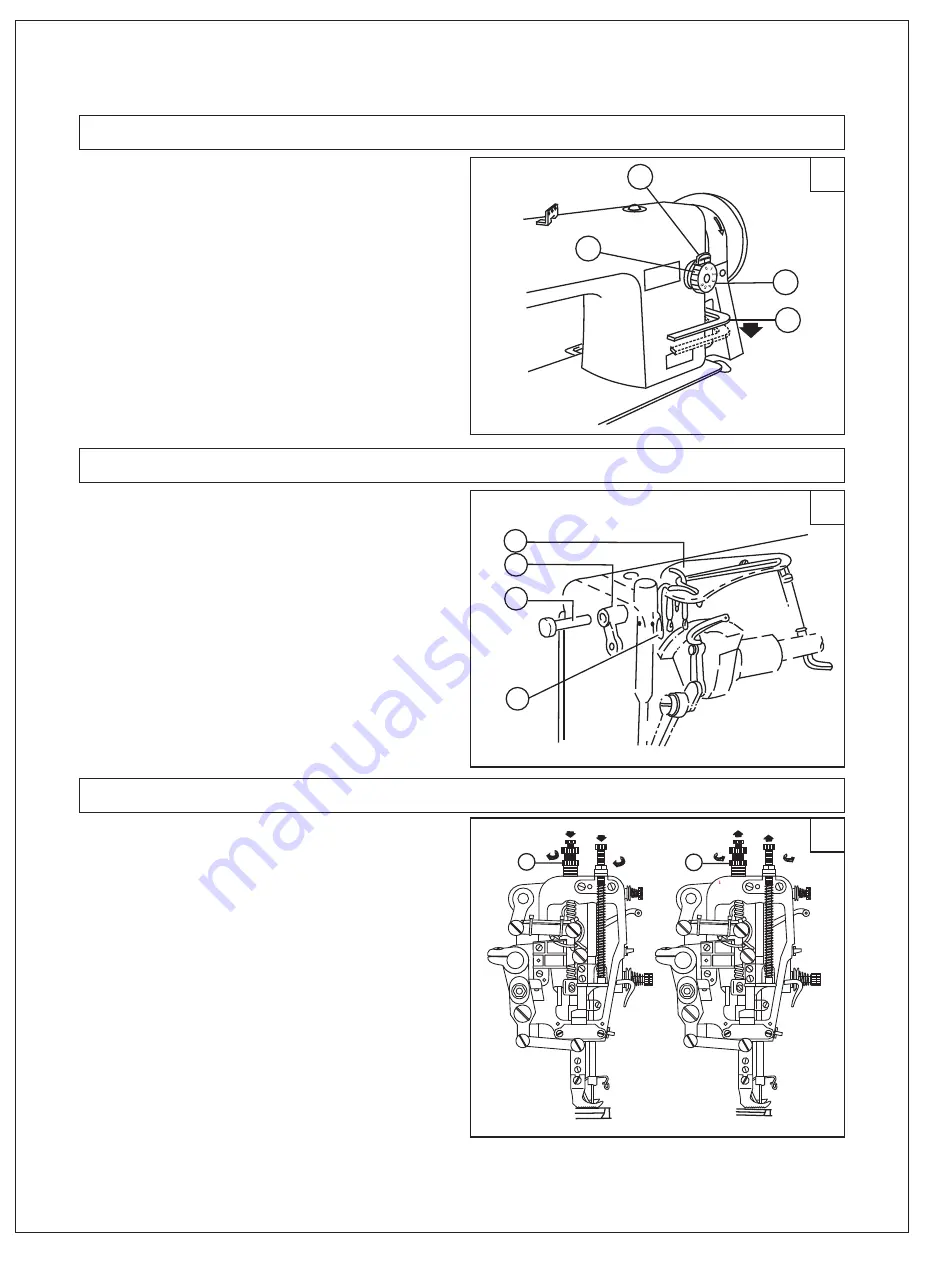

Pressure on presser foot is to be adjusted in

accordance with materials to be sewn. Loosen lock

nut (A). If heavy materials to be sewn, turn pres-

sure regulating thumb screw clockwise as shown

Fig.20 (a) to increase the pressure .While light mate-

rials to be sewn, turn the pressure regulating thumb

screw counter clockwise as shown in Fig. 20 (b) to

decrease the pressure on presser foot, then tighten

lock nut (A).

The pressure of presser foot is proper as the

sewing materials can be fed normally.

.

.

17.Adjusting the pressure of presser foot (Fig 15.)

15.Setting the stitch length and controlling the reverse sewing (Fig 13)

13

-7-

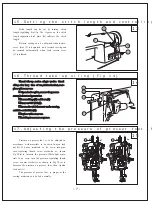

Thread take-up section adopts woolen thread

oiling. after long time of use, its function lost, so re-

place with a new one.

Open the face plate, remove the pressure

①

screw, lock nut and presser bar.

Renove Hinge(A) and Lever(B)

②

Draw out Oil Wick(C).

③

Loosen the wick fix screw on the arm top,

④

and take out Set Plate(D).

Replace with a new one.

⑤

Installing is a reverse sequence.

⑥

16.Thread take-up oiling (Fig 14)

14

C

A

B

D

A

B

C

D

Stitch length can be set by turning stitch

length regulating dial(A). The figures on the stitch

length regulation dial plate (B) indicate the stitch

length.

Reverse sewing can be obtained when feed re-

verse lever (C) is depressed and forward sewing can

be restored automatically when feed reverse lever

(C) is released.

.

.