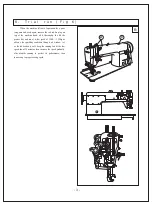

The position of the thread guide affects sewing

quality, so it must be adjusted according to the materials

to be sewn.

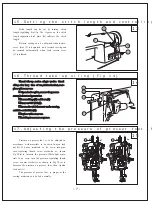

20.Adjusting the tension of needle thread & bobbin thread (Fig20

、

21 22)

、

21

-9-

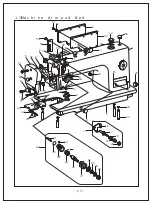

20

19

A

B

C

D

5-8mm

a

b

c

d

e

Fig.20 shows the various type of stitch forms.

Normal stitch form should be as shown in

Fig.20(a). When abnormal stitches occur with puck-

e ring or thread breakage, the tension of needle

thread and bobbin thread must be adjusted

accordingly

(a) The needle thread tension is too strong or

the bobbin thread tension is too weak. turn the ten-

sion regulating thumb nut counter clockwise to

make the needle thread get less tension or tignten

the bobbin case tension regulating screw with small

plastic screw driver to make the bobbin thread get

more tension(Fig.21).

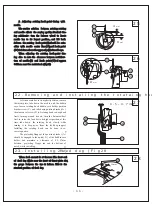

thread take-up spring(C) to zero, and to turn ten-

sion stud (B) clockwise until spring ( C ) just comes

into contact with the stop slot on the thread take-up

spring regulator, then to further turn tension stud

(B) counter-clockwise by 1/2 turn After adjustment,

tighten tension stud set screw (A).

2) Adjusting the sewing range of thread

take-up spring (Fig 19)

Loosen set screw (B), turn tension complete

( C ) clockwise to inerease the sewing range or turn

tension complete (C) counter clockwise to decrease

the sewing range.

Before delivery, the thread take-up spring is

properly adjusted, Readjustment is needle only in

the case of sewing special materials or with special

thread.

.

.

.

.

Thread guide

position

Material

Heavy

Medium

Light

Leftward

Center

Rightward