37

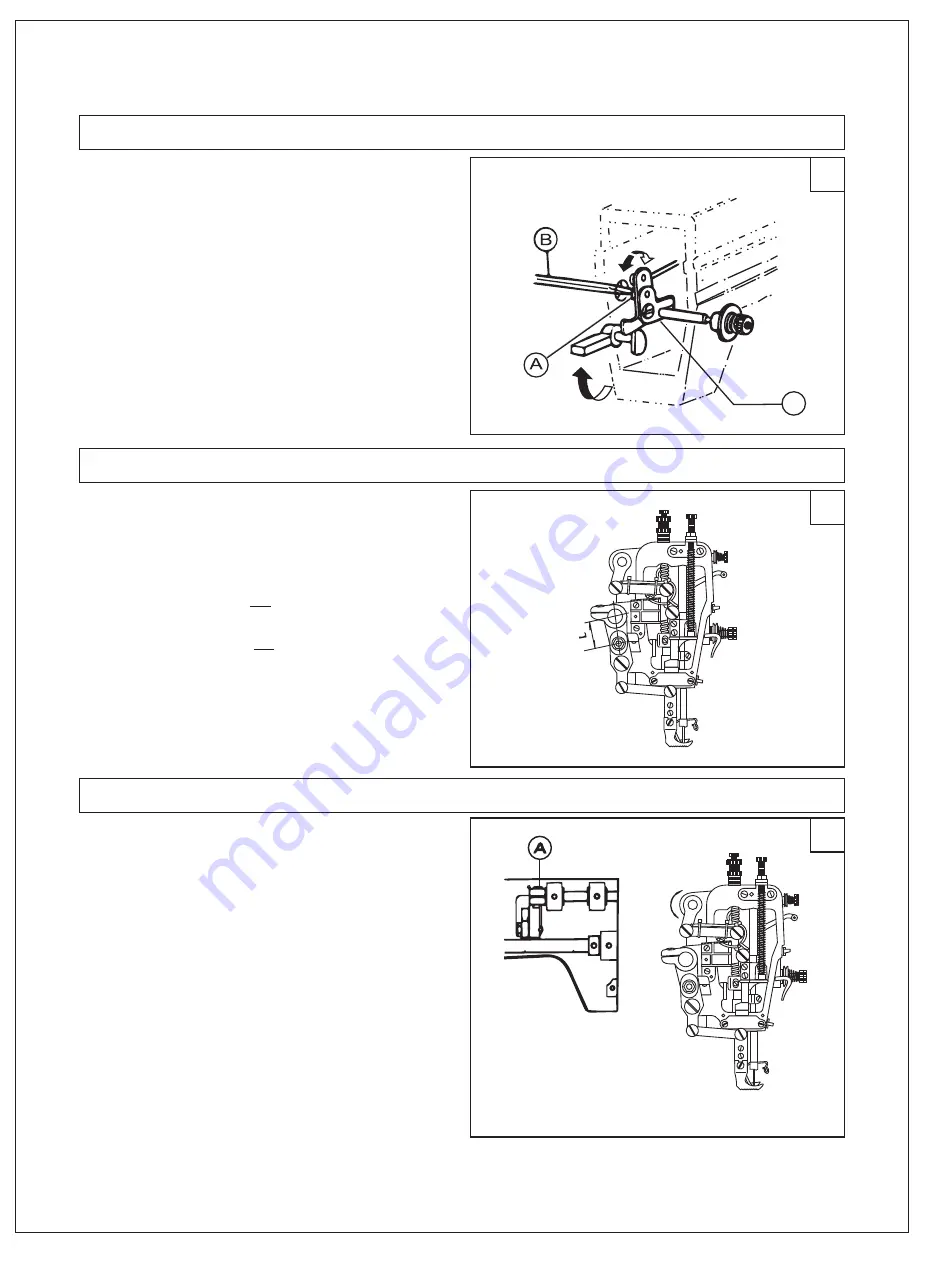

The

tension discs should be pushed apart to open

when the presser foot is lifted. But the open timing of the

tension discs can be adjusted as follows: Remove face

plate and the rubber plug at rear side of arm and loosen

screw (A) of the knee lifting lever (left), then the tension

releasing cam can be moved leftward or rightward when

the cam is moved rightward, it is later to open, otherwise

it is earlier to open.

.

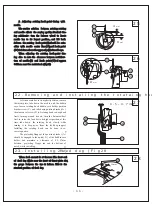

29. Adjusting presser foot alternate lift mechanism (Fig 37)

27. Adjusting the tension releasing mechanism (Fig 35)

35

-14-

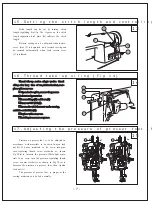

28. Upper feed adjustment (Fig 36)

36

Right

D

During the sewing, the center gauge (L) between

the walking foot sliding block and its shaft can be adjusted

according to the differences of the friction coefficients of

the friction coefficients of materials and the sewing pro-

cess.

Method: Increase L the upper feed amount

enlarged

reduce L the upper feed amount

shorten

For special sewing requirements, for example, the

upper layer of material needs more amount than the lower

layer does, in this case, adjustment can be done in the

range of above theory for operation.

.

.

.

.

During the sewing, the alternate lift amount can

be adjusted accoding to the nature of material. In general

sewing, the amount of walking foot is 5.5mm, and the

presser foot lift amount is 3.5mm.

Method: loosen the screw A. turn presser foot

front crank upward to increase the amount of walking

foot; turn it downward to reduce the presser foot amount,

the range of adjusting amount is not too large. After

adjustment, tighten the screw.

.

.

Left

Above

Under