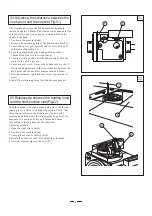

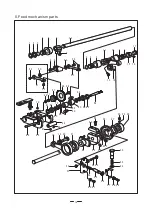

21.Position between the rotating hook and the needle

(Fig.18)

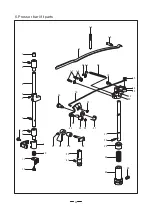

22.Adjusting the position of the needle bar(Fig.19)

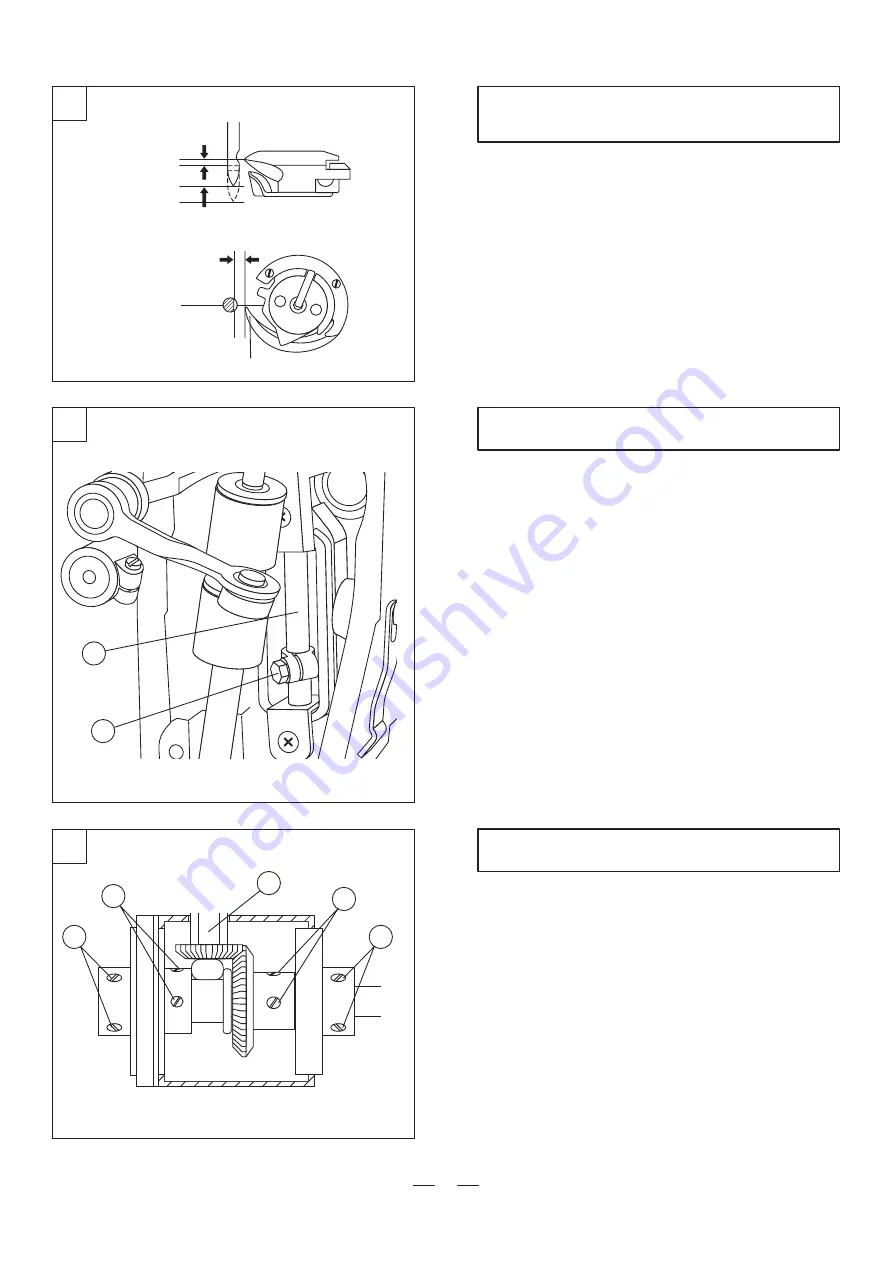

33.Adjusting the position of the hook point(Fig.20)

18

19

20

8

1.6mm

0.05mm

Hook point

Lowerend of

the needle

B

A

D

C

B

A

D

When the hook point is lifted by 1.8mm from its lowest

position, the position of the needle and the rotating hook is

as shown in Fig.18:

1.The upper end of the needle eye is

0.3mm lower than

the hook point 1;

2.The hook point aligns with the point hook groove

directly;

3.The clearance between the hook point and the needle

groove is approx 0-0.05mm.

When the needle bar is 1.8mm lifted from its lowest

position,adjust the position of the needle bar to make the

needle eye

0.3mm lower than the hook point 1.

1.Turn the balance wheel by hand until the needle bar is

1.8mm lifted form its lowest position;

2.Move the needle bar B up ward and downward as

required;

3.After adjustment, tighten the needle bar connecting

screw A.

1.Lay down the machine head;

2.Remove the front retaining plate of the bobbin case

bracket;

3.Loosen the bevel gear two screws B and the two set

screws A and D of the lower shaft;

4.Turn the balance wheel by hand until the needle is

1.8mm lifted from its lowest position;

5.Turn the hook shaft bevel gear C until the hook point

aligns with the center of the needle groove;

6.After adjustment, tighten the lower shaft bevel gear

screw B,and tighten the screw A and D until screw A,B,

and D run in one line;

7.Install the front retaining plate of the bobbin case

bracket.

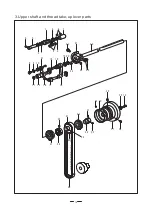

Upper end of

the needle eye

Up 2.0mm

Needle center

Hook point