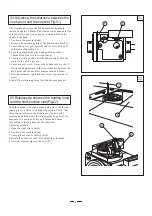

3. Preparation (Fig.1)

1. Brief introduction

2. Main technical specifications

1

1

Application

Max.sewing speed

Presser foot lift volume

Max.stitch length

Needle bar stroke

Needle

Rotating hook

Lubrication

Motor power

2 5 0 0 r . p . m

7 m m b y h a n d , 9 m m b y k n e e

5 m m

Medium and heavy duty materials

O i l i n g b y h a n d

3 7 0 W

3 8 m m

DP

5 14

20

~

#

#

H o r i z o n t a l h o o k

A

C

B

GC20616 adopts link thread take-up,driven roller poresser

foot, and timing feed of roller and needle. Vertical hooks

for threading looping forms lockstitch seam. The upper

shaft and rock shaft are driven by teeth-type synchronic

belt. In addition, the main working parts adopt needle or

ball bearing. Knob - type stitch length regulator makes the

operation easy.

This model is widely used in manufacturing arc products

as high-quality leather shoes, packing and gloves.

Before delivery, the machine parts are coated with rust preventive gerase, which may be hardened and contaminated by dust

during storage and shipment. The grease must be removed by clean cloth with gasoline.

Though every machine is confirmed by strict inspection and test before delivery, the machine parts may be loosened or

deformed after long distance transportation with jolt. A thorough examination must be performed after cleaning the machine.

Turn the balance wheel to see if there is running obstruction, parts collision, uneven resistance or abnormal noise. If these

exist, adjustment must be made accordingly before running.

1. Cleaning the machine

2. Inspection

4. Installing the machine head (Fig.1)

Put the cushion A and B into the table cutout, and set the

connecting hook C on the cushion B, then turn the machine

head freely till it is seated on the frame of table cutout.