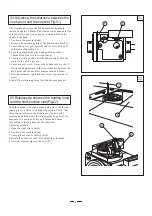

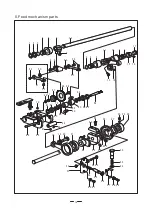

17.Adjusting the tension of bobbin thread and needle

thread(Fig.14)

Normal stitch form should be as shown in Fig.14 A.

When abnormal stitches occur with puckering or thread

breakage,the tension of bobbin thread and needle thread

should be adjusted accordingly.

1.If the stiches are as shown I Fig.14 B,which means

that the tension of the needle thread is too strong or

the tension of the bobbin thread is too weak,turn the

tension regulating thumb nut counter clockwise to

weaken the tension of the needle thread, or tighten the

bobbin case tension regulating screw with small

screwdriver to strengthen the tension of the bobbin

thread.

2.If the tension of the needle thread is too weak or the

tension of the bobbin thread is too strong as shown in

Fig.C,turn the tension regulating thumb nut clockwise

to strengthen the tension of the needle thread,or loosen

the bobbin case regulating screw with small screwdriver

to weaken the tension of the bobbin thread.

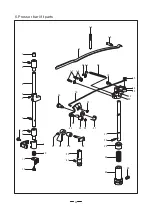

18.Adjusting the swing range and the tension of the

thread take-up spring(Fig.15)

14

15

6

L o o s e n

T i g h t e n

S t r e n g t h e n

W e a k e n

T e n s i o n o f

n e e d l e t h r e a d

B

A

B

A

C

B

Generally,before delivery,the thread take-up spring should

have been adjusted properly.

Therefore, it should be

re-adjusted only when sewing with special material or

special thread.

Loosen the thread take-up spring shaft adjusting nut B,

then turn the thread take-up spring shaft A to adjust its

tension. Turn the thread take-up spring shaft couter

clockwise to strengthen the tension of the thread take-up;

on the contrary,to weaken the tension of the thread take-up.

Tighten the adjusting nut B.

Loosen the position plate screw, turn the thread take-up

position plate counter clockwise to widen the range of the

thread take-up spring;on the contrary,to narrow the range

of the thread take-up spring. After adjustment,tighten the

position plate screw.