Easy Travel

– Service Manual

Rev. 0401

46

Figure 47

4.

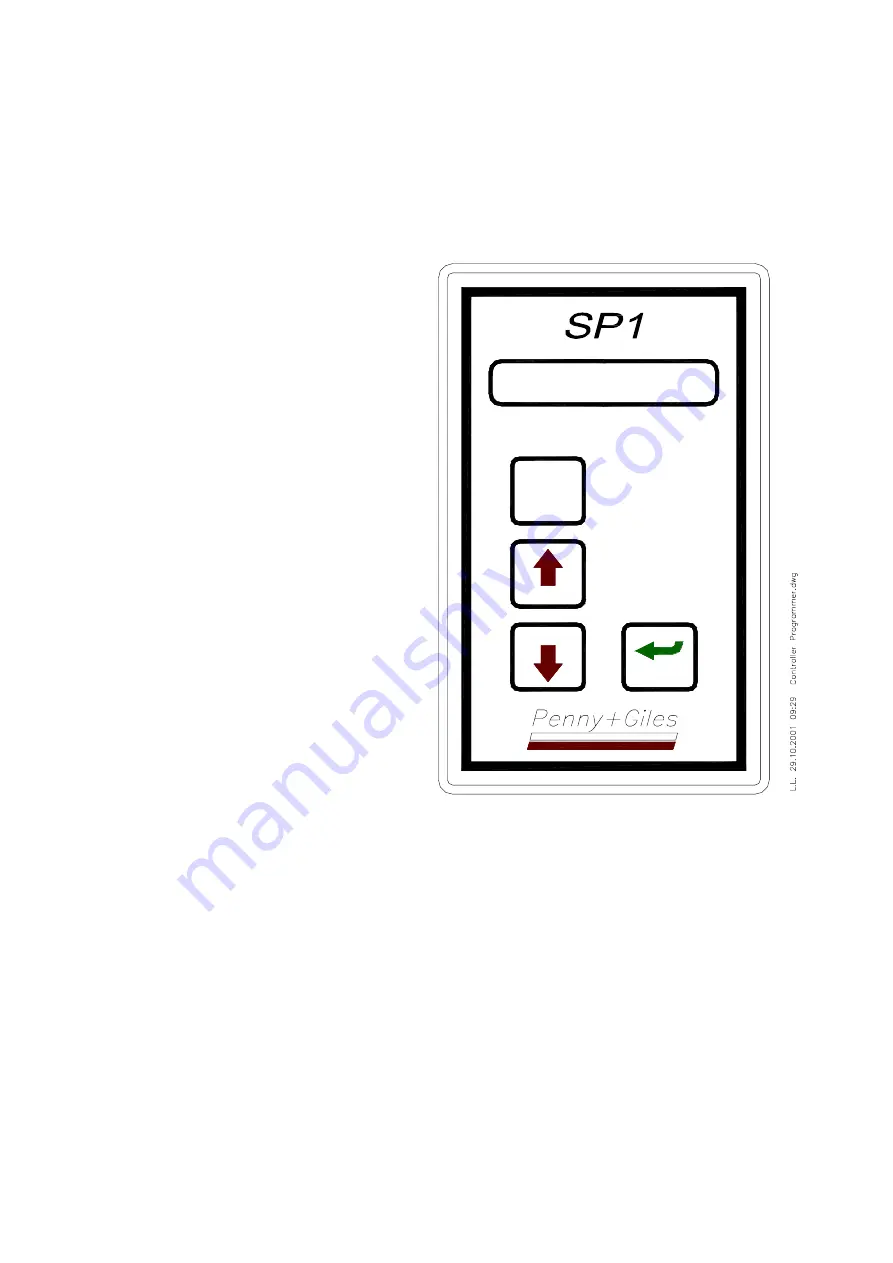

PROGRAMMING OF THE SOLO CONTROLLER

4.1 Introduction

The

EasyTravel

electric system is operated by the Solo Controller manufactured by Penny & Giles Tech-

nologies Ltd. (UK).

4.2 The

SP1

Programmer

The SP1 is a handheld programmer for use

with the Solo controller.

The programmer is a menu-driven device,

which plugs directly into the controller.

The SP1b Programmer (Engineering

Version) can set all of the key controller

speed, acceleration and braking characteris-

tics, and allows different settings to be tried

out while the programmer is still plugged

into the controller. A context-sensitive help

function is available to guide users through

the menus and the SP1b can also display

error messages from the controller. This

allows any problems with the vehicle

electrical system to be identified and

corrected quickly.

WARNING

Programming should only be conducted by competent personnel with in-depth knowledge of Penny

& Giles electronic controllers. Incorrect programming could result in an unsafe set-up of a vehicle for

a user. Tzora Active Systems accepts no liability for losses of any kind if the programming of the

controller is altered from factory pre-set values.

Yes

No

Enter

?

Summary of Contents for Easy Travel Elite

Page 1: ...Service Manual...