LARA-R2 series - System Integration Manual

UBX-16010573 - R02

Objective Specification

Design-in

Page 72 of 148

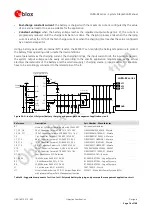

2.2.1.6

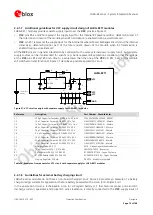

Additional guidelines for VCC supply circuit design

To reduce voltage drops, use a low impedance power source. The series resistance of the power supply lines

(connected to the

VCC

and

GND

pins of the module) on the application board and battery pack should also be

considered and minimized: cabling and routing must be as short as possible to minimize power losses.

Three pins are allocated for

VCC

supply. Several pins are designated for

GND

connection. It is recommended to

properly connect all of them to supply the module to minimize series resistance losses.

In case of modules supporting 2G radio access technology, to avoid voltage drop undershoot and overshoot at

the start and end of a transmit burst during a GSM call (when current consumption on the

VCC

supply can rise

up as specified in the

LARA-R2 series

Data Sheet

[1]), place a bypass capacitor with large capacitance (at least

100 µF) and low ESR near the

VCC

pins, for example:

330 µF capacitance, 45 m

ESR (e.g. KEMET T520D337M006ATE045, Tantalum Capacitor)

To reduce voltage ripple and noise, improving RF performance especially if the application device integrates an

internal antenna, place the following bypass capacitors near the

VCC

pins:

68 pF capacitor with Self-Resonant Frequency in 800/900 MHz range (e.g. Murata GRM1555C1E560J)

15 pF capacitor with Self-Resonant Frequency in 1800/1900 MHz range (e.g. Murata GRM1555C1E150J)

8.2 pF capacitor with Self-Resonant Frequency in 2500/2600 MHz range (e.g. Murata GRM1555C1H8R2D)

10 nF capacitor (e.g. Murata GRM155R71C103K) to filter digital logic noise from clocks and data sources

100 nF capacitor (e.g Murata GRM155R61C104K) to filter digital logic noise from clocks and data sources

A suitable series ferrite bead can be properly placed on the

VCC

line for additional noise filtering if required by

the specific application according to the whole application board design.

C2

GND

C3

C4

LARA-R2 series

52

VCC

53

VCC

51

VCC

C1

C6

3V8

+

Recommended for

cellular modules

supporting 2G

C5

Recommended for

cellular modules

supporting LTE band-7

Figure 30: Suggested schematic for the VCC bypass capacitors to reduce ripple / noise on supply voltage profile

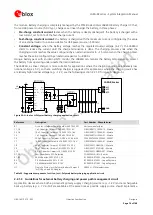

Reference

Description

Part Number - Manufacturer

C1

8.2 pF Capacitor Ceramic C0G 0402 5% 50 V

GRM1555C1H8R2DZ01 - Murata

C2

15 pF Capacitor Ceramic C0G 0402 5% 50 V

GRM1555C1H150JA01 - Murata

C3

68 pF Capacitor Ceramic C0G 0402 5% 50 V

GRM1555C1H680JA01 - Murata

C4

10 nF Capacitor Ceramic X7R 0402 10% 16 V

GRM155R71C103KA01 - Murata

C5

100 nF Capacitor Ceramic X7R 0402 10% 16 V

GRM155R71C104KA01 - Murata

C6

330 µF Capacitor Tantalum D_SIZE 6.3 V 45 m

T520D337M006ATE045 - KEMET

Table 23: Suggested components to reduce ripple / noise on VCC

The necessity of each part depends on the specific design, but it is recommended to provide all the bypass

capacitors described in Figure 30 / Table 23 if the application device integrates an internal antenna.

ESD sensitivity rating of the

VCC

supply pins is 1 kV (Human Body Model according to JESD22-A114).

Higher protection level can be required if the line is externally accessible on the application board, e.g. if

accessible battery connector is directly connected to

VCC

pins. Higher protection level can be achieved by

mounting an ESD protection (e.g. EPCOS CA05P4S14THSG varistor array) close to accessible point.