LILY-W1 series - System integration manual

UBX-15027600 - R09

Design-in

Page 16 of 64

C1 - Public

Therefore, module integrators must either follow exactly one of the antenna reference design used

in the module’s FCC type approval and detailed in Annex B or certify their own designs.

2.2.1

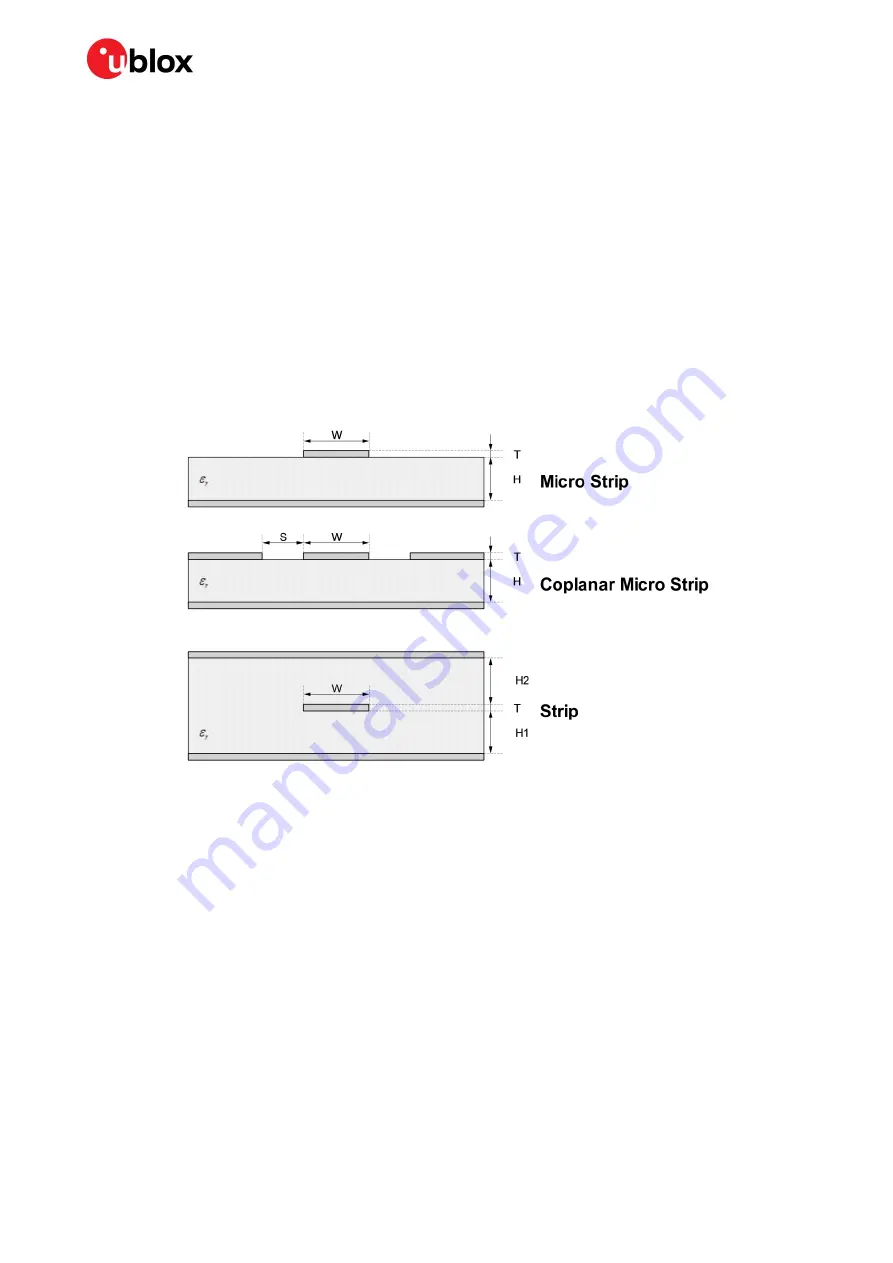

RF transmission line design (LILY-W131 only)

RF transmission lines such as the one from the

ANT

pin up to the related antenna connectors must

be designed so that the characteristic impedance is as close as possible to 50

Ω

. Figure 4 illustrates

the design options and the main parameters to be taken into account when implementing a

transmission line on a PCB:

•

The micro strip (a track coupled to a single ground plane, separated by dielectric material),

•

The coplanar micro strip (a track coupled to ground plane and side conductors, separated by

dielectric material).

•

The strip line (a track sandwiched between two parallel ground planes, separated by dielectric

material).

The coplanar micro strip is the most common configuration for a printed circuit board (PCB).

Figure 4: Transmission line trace design

To properly design a 50

Ω

transmission line, the following remarks should be taken into account:

•

The designer should provide enough clearance from surrounding traces and ground in the same

layer; in general a trace to ground clearance of at least two times the trace width should be

considered and the transmission line should be ”guarded” by ground plane area on each side.

•

The characteristic impedance can be calculated as first iteration using tools provided by the layout

software. It is advisable to ask the PCB manufacturer to provide the final values that are usually

calculated using dedicated software and available stack-ups from production. It could also be

possible to request an impedance coupon on panel’s side to measure the real impedance of the

traces.

•

FR-4 dielectric material, although its high losses at high frequencies can be considered in RF

designs providing that :

o

RF trace length must be minimized to reduce dielectric losses.

o

If traces longer than few centimeters are needed, it is recommended to use a coaxial

connector and cable to reduce losses.

o

Stack-up should allow for wide 50

Ω

traces and at least 200 µm trace width is

recommended to assure good impedance control over the PCB manufacturing process.