LILY-W1 series - System integration manual

UBX-15027600 - R09

Product testing

Page 53 of 64

C1 - Public

6

Product testing

6.1

u-blox in-series production test

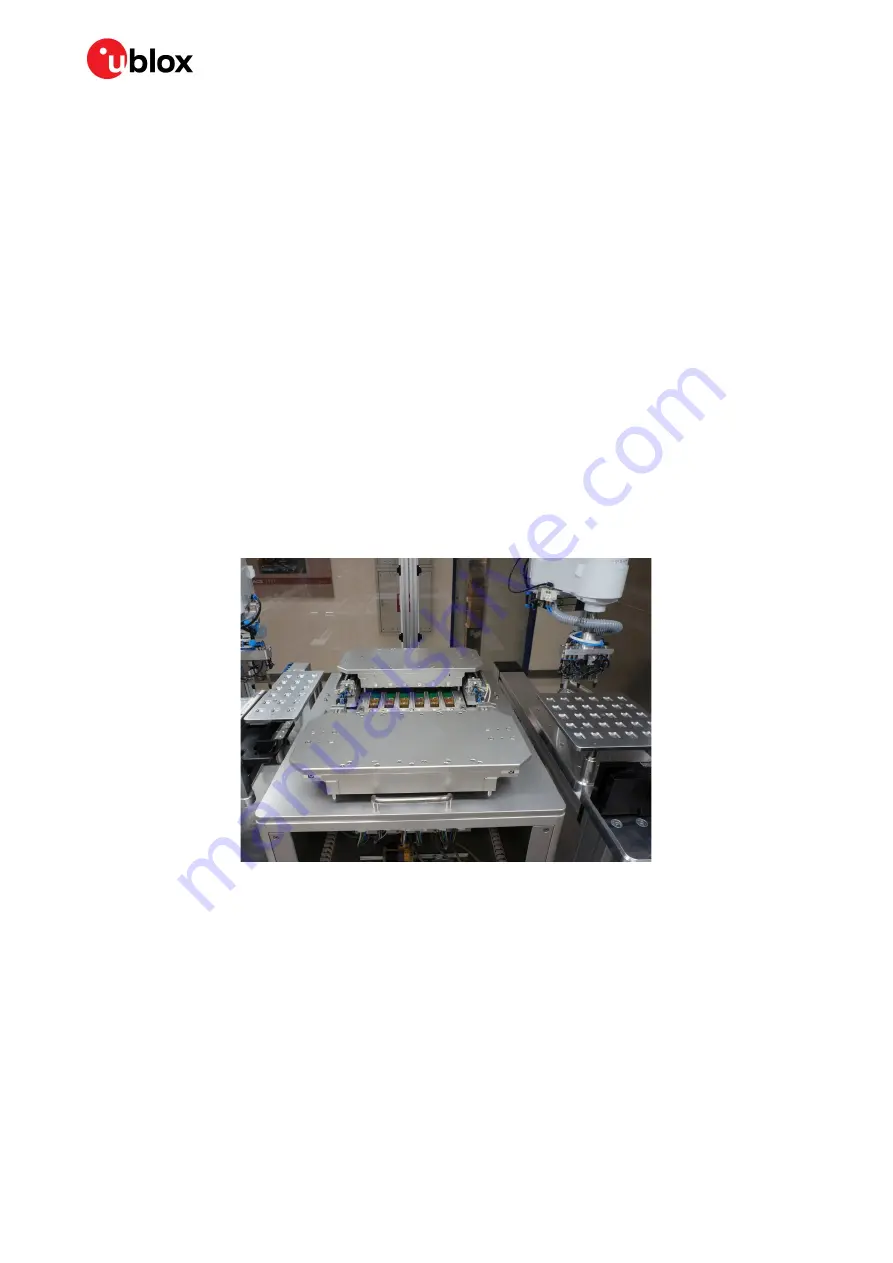

u-blox focuses on high quality for its products. All units produced are fully tested automatically in

production line. Stringent quality control process has been implemented in the production line.

Defective units are analyzed in detail to improve the production quality.

This is achieved with automatic test equipment (ATE) in production line, which logs all production and

measurement data. A detailed test report for each unit can be generated from the system. Figure 14

illustrates typical automatic test equipment (ATE) in a production line.

The following typical tests are among the production tests:

•

Digital self-test (firmware download, MAC address programming)

•

Measurement of voltages and currents

•

Functional tests (SDIO and USB 2.0 interface communication)

•

Digital I/O tests

•

Measurement and calibration of RF characteristics in all supported bands (such as frequency

tuning of reference clock, calibration of transmitter power levels, etc.)

•

Verification of RF characteristics after calibration (that is, modulation accuracy, power levels,

spectrum etc. are checked to ensure they are all within tolerances when calibration parameters

are applied).

Figure 14: Automatic test equipment for module test

6.2

OEM manufacturer production test

As the testing is already done by u-blox, an OEM manufacturer does not need to repeat firmware tests

or measurements of the module RF performance or tests over analog and digital interfaces in their

production test.

However, an OEM manufacturer should focus on:

•

Module assembly on the device; it should be verified that:

o

Soldering and handling process did not damage the module components

o

All module pins are well soldered on device board

o

There are no short circuits between pins

•

Component assembly on the device; it should be verified that:

o

Communication with host controller can be established