SARA-G3 series - System Integration Manual

UBX-13000995 - R06

Objective Specification

Design-in

Page 153 of 218

2.10

Module footprint and paste mask

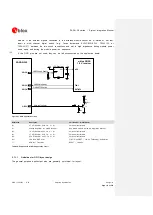

describe the suggested footprint (i.e. copper mask) and paste

mask layout for SARA-G3 modules: the proposed land pattern layout reflects the modules’ pads layout,

while the proposed stencil apertures layout is slightly different (see the F’’, H’’, I’’, J’’, O’’ parameters

compared to the F’, H’, I’, J’, O’ ones).

The Non Solder Mask Defined (NSMD) pad type is recommended over the Solder Mask Defined (SMD)

pad type, implementing the solder mask opening 50 µm larger per side than the corresponding copper

pad.

The recommended solder paste thickness is 150 µm, according to application production process

requirements.

K

M1

M1

M2

E

G

H’

J’

E

ANT pin

B

Pin 1

K

G

H’

J’

A

D

D

O’

O’

L

N

L

I’

F’

F’

K

M1

M1

M2

E

G

H’’

J’’

E

ANT pin

B

Pin 1

K

G

H’’

J’’

A

D

D

O’’

O’’

L

N

L

I’’

F’’

F’’

Stencil: 150

µm

Figure 63: SARA-G3 series modules suggested footprint and paste mask (application board top view)

Parameter

Value

Parameter

Value

Parameter

Value

A

26.0 mm

G

1.10 mm

K

2.75 mm

B

16.0 mm

H’

0.80 mm

L

2.75 mm

C

3.00 mm

H’’

0.75 mm

M1

1.80 mm

D

2.00 mm

I’

1.50 mm

M2

3.60 mm

E

2.50 mm

I’’

1.55 mm

N

2.10 mm

F’

1.05 mm

J’

0.30 mm

O’

1.10 mm

F’’

1.00 mm

J’’

0.35 mm

O’’

1.05 mm

Table 37: SARA-G3 series modules suggested footprint and paste mask dimensions