TOBY-L4 series - System Integration Manual

UBX-16024839 - R04

Design-in

Page 116 of 143

2.13

Module footprint and paste mask

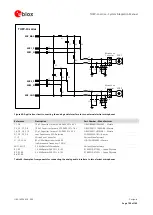

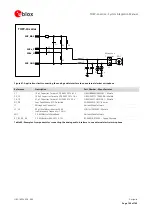

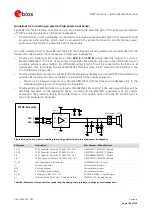

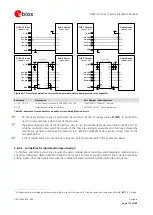

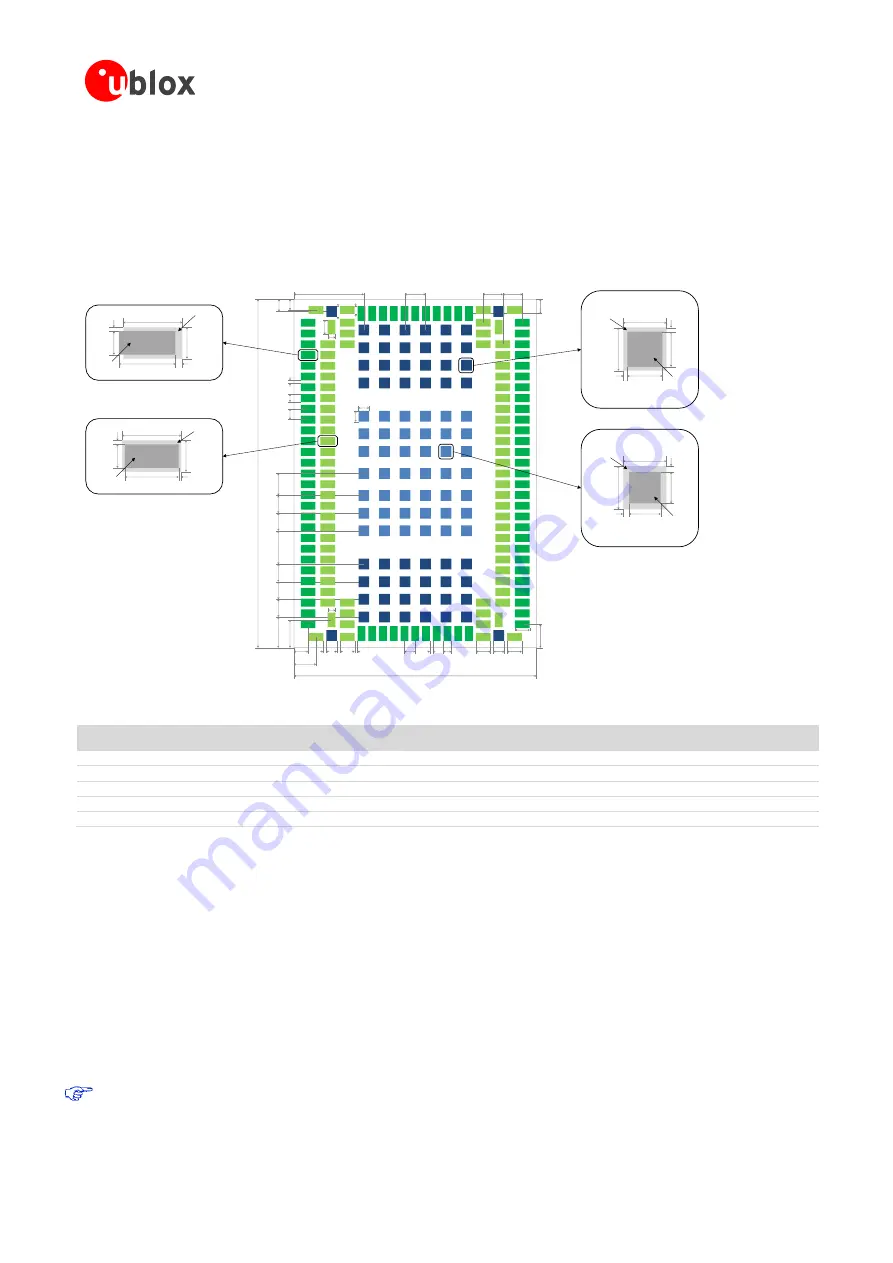

Figure 68 and Table 51 describe the suggested footprint (i.e. copper mask) and the paste mask (i.e. stencil)

layout for TOBY-L4 series modules, to be implemented on the application PCB.

The proposed land pattern layout (i.e. the footprint, the application board top-layer copper mask) reflects the

modules’ pads layout, with the pads on the application board designed as the LGA pads of the module.

I

A

D

F

K

M1

M1

M2

P2

B

G1

H

J

L

N

M1

M1

M3

I

I

O

J

J

J

E

P3

F

P1

H

O

M1

H

G2

G2

G1

H

J

I

H

O

O

0.80

1.50

1.45

0.60

0.10

0.17

Copper

Paste

1.10

1.10

1.00

1.00

0.05

0.05

Paste

Copper

1.10

1.10

0.90

0.90

0.10

0.10

Paste

Copper

0.80

1.50

1.38

0.60

0.10

0.06

Paste

Copper

Figure 68: Suggested footprint and stencil design for TOBY-L4 series modules, to be implemented on application PCB (top view)

Parameter

Value

Parameter

Value

Parameter

Value

Parameter

Value

A

35.6 mm

G1

1.10 mm

K

3.15 mm

N

2.10 mm

B

24.8 mm

G2

2.00 mm

L

7.15 mm

O

1.10 mm

D

2.40 mm

H

0.80 mm

M1

1.80 mm

P1

1.10 mm

E

2.25 mm

I

1.50 mm

M2

3.40 mm

P2

1.25 mm

F

1.45 mm

J

0.30 mm

M3

2.25 mm

P3

2.85 mm

Table 51: Suggested footprint design dimensions for TOBY-L4 series modules, to be implemented on application PCB

The Non Solder Mask Defined (NSMD) pad type is recommended over the Solder Mask Defined (SMD) pad type,

implementing the solder mask opening 50 µm larger per side than the corresponding copper pad.

The suggested paste mask (i.e. stencil) layout to mount TOBY-L4 series modules on the application PCB is also

illustrated in Figure 68. Different stencil apertures layout for any specific pad is recommended:

Green marked pads: Paste layout enlarged on the lateral side and reduced on other sides (see Figure 68)

Light-Green marked pads: Paste layout reduced circumferentially to Copper layout (see Figure 68)

Blue marked pads: Paste layout reduced circumferentially 0.05 mm to Copper layout (see Figure 68)

Light-Blue marked pads: Paste layout reduced circumferentially 0.1 mm to Copper layout (see Figure 68)

The recommended solder paste thickness is 150 µm, according to application production process requirements.

These are recommendations only and not specifications. The exact mask geometries, distances and stencil

thicknesses must be adapted to the specific production processes (e.g. soldering) of the customer.