TOBY-L4 series - System Integration Manual

UBX-16024839 - R04

Design-in

Page 54 of 143

typical choice when the charging source has a relatively low nominal voltage (~5 V). If both a permanent primary

supply / charging source (e.g. ~12 V) and a rechargeable back-up battery (e.g. 3.7 V Li-Pol) are available at the

same time as possible supply source, then a suitable charger / regulator with integrated power path

management function can be selected to supply the module while simultaneously and independently charging

the battery. See sections 2.2.1.7, 2.2.1.8, and 2.2.1.4, 2.2.1.6, 2.2.1.10, 2.2.1.11 for specific design-in.

An appropriate primary (not rechargeable) battery can be selected taking into account the maximum current

specified in the

TOBY-L4 series Data Sheet

[1] during connected mode, considering that primary cells might have

weak power capability. See sections 2.2.1.5, and 2.2.1.6, 2.2.1.10, 2.2.1.11 for specific design-in.

The usage of more than one DC supply at the same time should be evaluated carefully: depending on the supply

source characteristics, different DC supply systems can result as mutually exclusive.

The usage of a regulator or a battery not able to support the highest peak of

VCC

current consumption specified

in the

TOBY-L4 series Data Sheet

[1] is generally not recommended. However, if the selected regulator or battery

is not able to support the highest peak current of the module, it must be able to support with adequate margin

at least the highest averaged current consumption value specified in the

TOBY-L4 series Data Sheet

[1]. The

additional energy required by the module during a 2G Tx slot can be provided by an appropriate bypass tank

capacitor or a super-capacitor with very large capacitance and very low ESR placed close to the module

VCC

pins. Depending on the actual capability of the selected regulator or battery, the required capacitance can be

considerably larger than 1 mF and the required ESR can be in the range of few tens of m

. Carefully evaluate

the super-capacitor characteristics since aging and temperature may affect the actual characteristics.

The following sections highlight some design aspects for each of the supplies listed above providing application

circuit design-in compliant with the module

VCC

requirements summarized in Table 7.

2.2.1.2

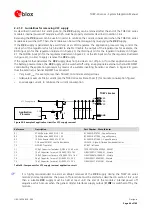

Guidelines for VCC supply circuit design using a switching regulator

The use of a switching regulator is suggested when the difference from the available supply rail source to the

VCC

value is high, since switching regulators provide good efficiency transforming a 12 V or greater voltage

supply to the typical 3.8 V value of the

VCC

supply.

The characteristics of the switching regulator connected to

VCC

pins should meet the following prerequisites to

comply with the module

VCC

requirements summarized in Table 7:

Power capability

: the switching regulator with its output circuit must be capable of providing a voltage

value to the

VCC

pins within the specified operating range and must be capable of delivering to

VCC

pins

the maximum peak / pulse current consumption during Tx burst at maximum Tx power specified in the

TOBY-L4 series

Data Sheet

Low output ripple

: the switching regulator together with its output circuit must be capable of providing a

clean (low noise)

VCC

voltage profile.

High switching frequency:

for best performance and for smaller applications it is recommended to select a

switching frequency

≥

600 kHz (since L-C output filter is typically smaller for high switching frequency). The

use of a switching regulator with a variable switching frequency or with a switching frequency lower than

600 kHz must be evaluated carefully since this can produce noise in the

VCC

voltage profile and therefore

negatively impact LTE/3G/2G modulation spectrum performance. An additional L-C low-pass filter between

the switching regulator output to

VCC

supply pins can mitigate the ripple at the input of the module, but

adds extra voltage drop due to resistive losses on series inductors.

PWM mode operation

: it is preferable to select regulators with Pulse Width Modulation (PWM) mode.

While in connected mode, the Pulse Frequency Modulation (PFM) mode and PFM/PWM modes transitions

must be avoided to reduce noise on

VCC

voltage profile. Switching regulators can be used that are able to

switch between low ripple PWM mode and high ripple PFM mode, provided that the mode transition occurs

when the module changes status from the idle/active modes to connected mode. It is permissible to use a

regulator that switches from the PWM mode to the burst or PFM mode at an appropriate current threshold.