USER GUIDE

Integrated Panel Dimensions 6

u-line.com

SAFETY •

INSTALLATION & INTEGRATION

• OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

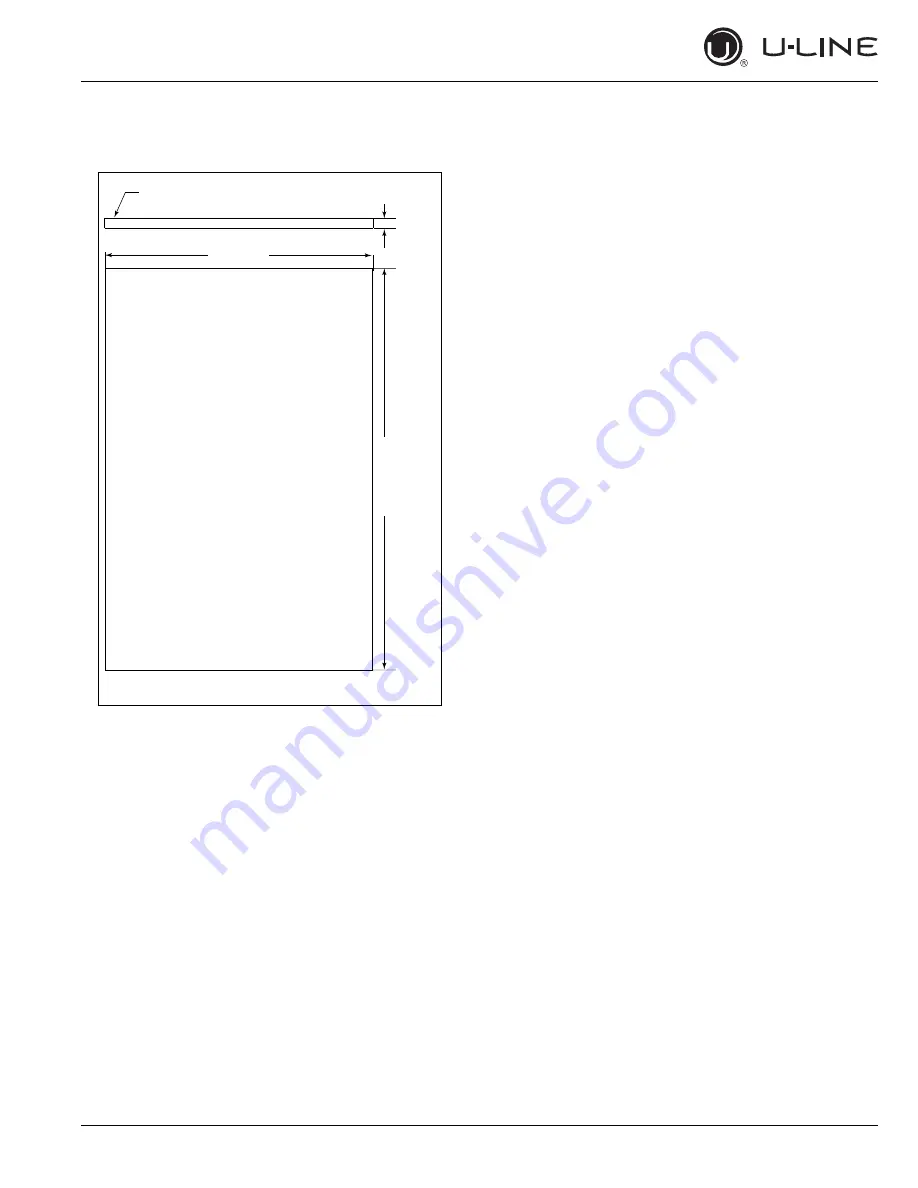

Extended Integrated Panel Dimensions

BACK SURFACE MUST HAVE AMPLE FLAT SURFACE

TO MOUNT OVERLAY PANEL FLAT AND WITHOUT

INTERFERENCE

23-3/8

"

(594 mm)

3/4"

(20 mm)

Integrated Panel

32-7/8"

to

33-7/8"

(834 mm

to

860 mm)*

* A minimum of 1" (25 mm) is required from the

floor to the bottom of the extended integrated

panel/frame for proper ventilation.