PAGE 5 OF 5

0823 IH-10947

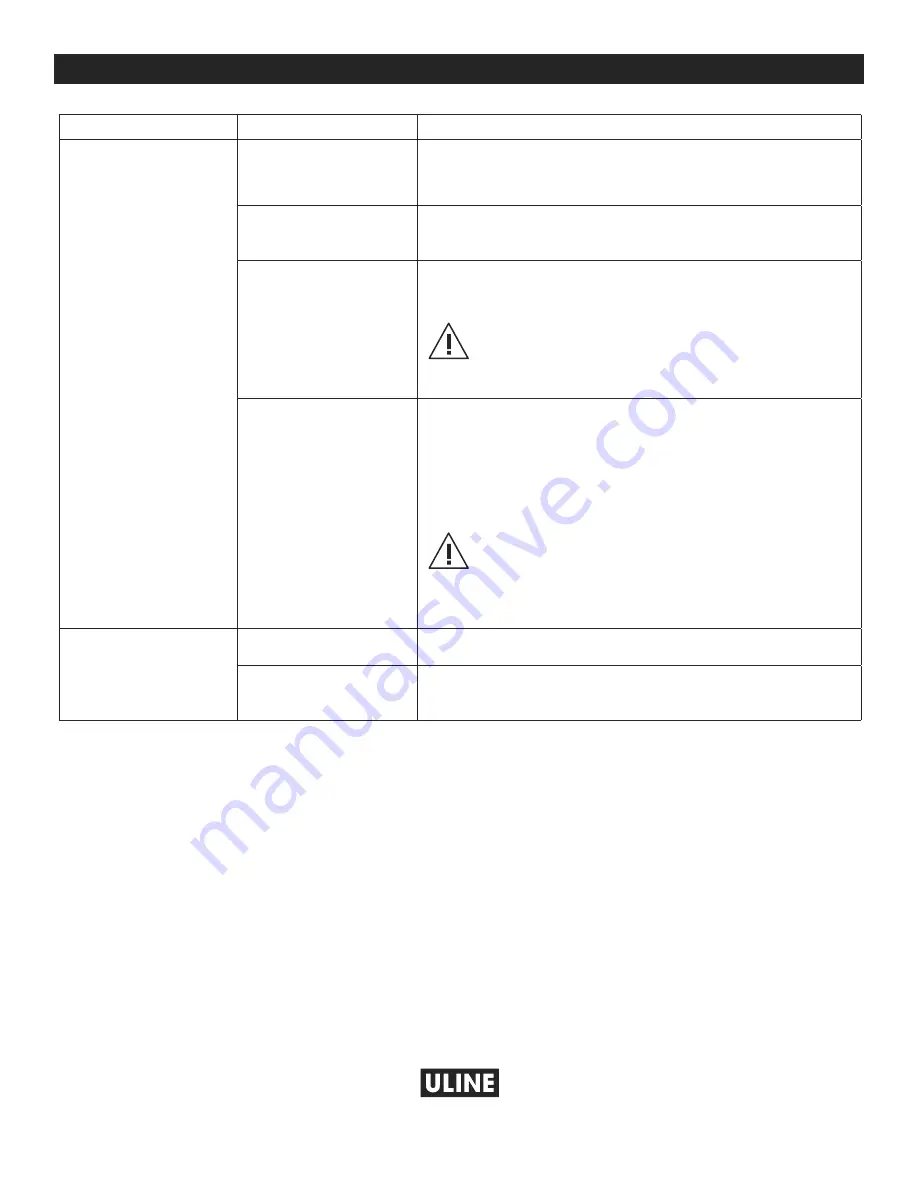

TROUBLESHOOTING

OPERATING ISSUE

CAUSES

RECOMMENDATIONS

Low or no

adhesive flow.

No heat.

Check to see that the electrical 120 Vac service is turned on.

Thermal fuse in the thermostat may have blown.

Shutdown procedure

was not observed.

Allow the glue gun to heat up for at least 30 minutes.

Plugged tip.

If the glue gun was left overnight, the tip may be plugged.

This may block adhesive flow and cause backmelt.

CAUTION! Do not force adhesive. Clear the tip with

a small nail or paperclip. Extrude the remaining

adhesive stick and one new adhesive stick to clear

the opening.

Backmelt.

Remove the clip and feeder from the track of the glue

gun. Push the existing adhesive stick back into the sleeve

approximately 3/4" with a new adhesive stick. Remove the

new adhesive stick before it melts and look into the black

sleeve. Look for a thin skin of adhesive around the inside of

the black sleeve. Scrape this skin toward the heat block.

CAUTION! Do not damage the black sleeve. Extrude

one adhesive stick to clear the sleeve.

To avoid backmelt, observe the start-up and shut-down

procedures. Do not force adhesive through the glue gun.

Dripping nozzle.*

Backmelt.

Refer to preceding paragraph on backmelt.

Contaminated

adhesive.

Keep adhesive clean and free of contamination.

*Thermal expansion may cause some dripping during start-up. This is normal.

1-800-295-5510

uline.com