CLR2160 — Clear Ice Maker

www.U-LineService.com

12

08/2006

Checking Door Alignment

The unit’s door is aligned at the factory before shipment.

However, its alignment could have been disturbed during

shipment or during door panel installation.

IMPORTANT

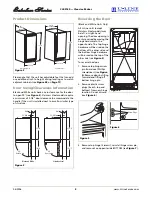

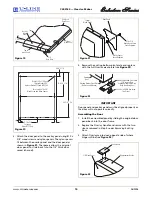

Properly aligned, the door should be 1/8" below the top of

the unit’s cabinet, NOT flush with the top (see

Figure 27

).

1. Compare the top edge of the door to the top edge of

the cabinet.

2. If the door edge is 1/8" below and parallel to the top of

the cabinet, go on to

6 Prepare Plumbing

. If it is not,

note whether the side opposite the hinge needs to be

moved UP or DOWN, and use the following procedure.

Note:

If door is adjusted correctly, but panel is not square

with the adjacent cabinets, slight adjustments can be

made by drilling the holes in the vinyl coated steel panel

slightly oversized. See

Figure 21

on

Page

10

.

Adjusting Door Alignment

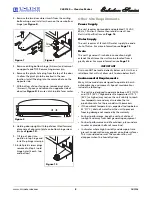

1. Remove top hinge screw

pin (Phillips screwdriver,

see

Figure 28

). Remove

door by tilting forward

and lifting off bottom

hinge pin.

2. With door upside-down,

loosen but do not remove

the two screws on the

door’s bottom hinge plate.

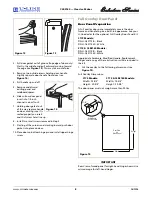

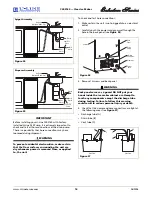

3. See

Figure 29

. If the top far edge of the door needs to

move UP, move the hinge plate toward the outside of

the door and retighten screws. If the top far edge of the

door needs to move DOWN, move the hinge plate

toward the inside of the door and retighten screws.

4. Mount the door to recheck alignment and repeat Steps

2 and 3 if further adjustment is necessary.

5. When top edge of door is parallel to top edge of

cabinet, remove the door and ensure the two screws

are secure.

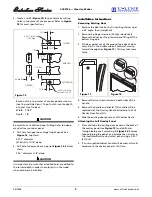

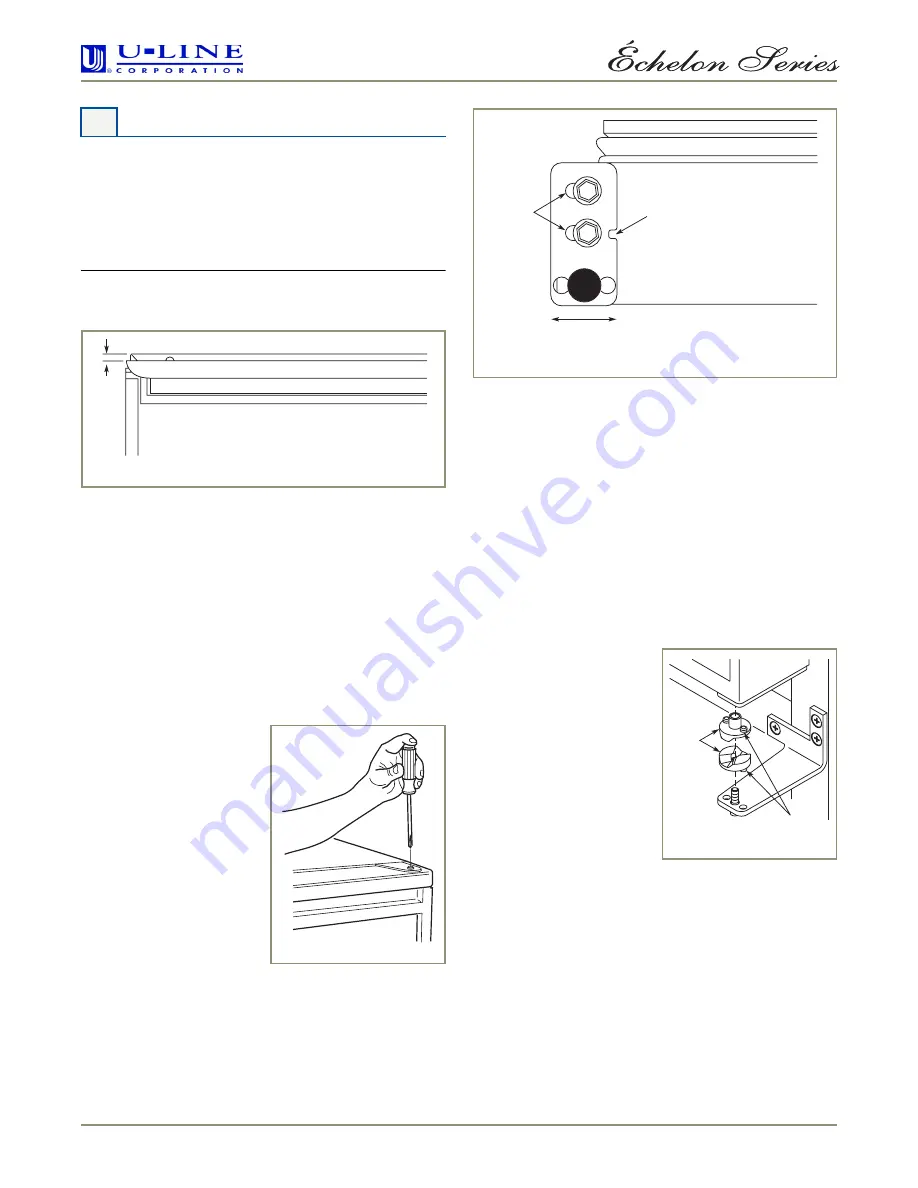

6. Remove the door closers from the bottom hinge, clean

thoroughly and lubricate the mating surfaces with

petroleum jelly.

7. Reinstall the closers, lining

up the bosses with holes in

hinge and hinge plate (see

Figure 30

).

8. Mount the door, install top

hinge pivot pin and go on

to

6 Prepare Plumbing

.

5 Adjust Door

1/8"

Figure 27

ULIN_0133_A

Figure 28

Notch

(must face toward

center of door)

Slotted

Mounting

Holes

Raise

Outside

Door Edge

Lower

Outside

Door Edge

Figure 29

Door

Closer

Inserts

Boss

Figure 30